- Everything you need to know about ABS 3D printing - March 9, 2023

- How a New Generation of 3D Printers is Accelerating the NPD Process - November 16, 2022

- Buyer’s Guide to an Industrial 3D Printer - October 31, 2022

A common misconception these days is that professional 3D printers are costly, big and most often cannot be used in office environments. If this is what you’ve been thinking too, then you may not realize that the technology has become more accessible than ever. Here is a buyer’s guide to help you on your journey to find the right professional desktop 3D printer.

Today’s professional desktop 3D printers are affordable, have decent build volumes, and can be safely used in office environments. Moreover, these give you unprecedented advantages over your existing traditional manufacturing processes – not to mention your existing desktop 3D printers. Is a professional desktop 3D printer a good fit for you?

What’s your 3D printer Status?

No in-house 3D printer

An obvious starting point is simply having an in-house 3D printer. Today, 3D printers are becoming commonplace in new product development (NPD) cycles. Many of the challenges faced by engineers can be quickly solved by using the power of 3D printing that enables faster prototyping. In-house 3D printers also enable implementation of design thinking principles to make products better.

The pain point of not having a 3D printer often means having longer NPD lead times, allowing a competitor to gain an advantage. So, what is the solution to having no 3D printer? Outsourcing! But note that outsourcing too has its problems.

Outsourcing costs

As mentioned, when you don’t have a 3D printer, the common route most engineers or manufacturers will take is to outsource their 3D printing jobs.

This is obviously the easiest way out but not always the most ideal. Outsourcing makes you dependent on the service provider and their capabilities. Outsourcing will be the most expensive option on a per part basis and will have an impact on the overall supply chain. You’ll likely face higher lead times, require more quality control, and need to expend more resources in logistics.

3D printing is relatively new to many organizations and even service providers are learning the technology. And so, outsourcing will in fact increase your costs rather than reducing it.

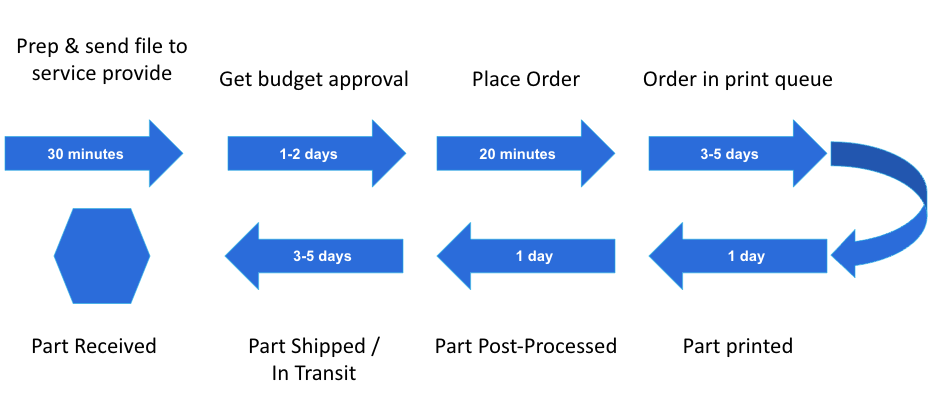

Outsourcing turnaround times

When you are outsourcing part manufacturing, you are basically relying on the partner to fulfill deliveries and follow your production and shipping timelines. Even a slight change in your production cycles has to be communicated to the outsourcing partner well in advance. This makes it difficult to reduce your turnaround times. This will be a long drawn process and it defeats the purpose of 3D printing which can help you quicken the pace of new product development and introduction to market.

Reduced throughput potential which leads to higher risk

The impact of the above two points results in a reduced throughput potential. This means that you are constantly at the risk of falling short of production, missing your delivery schedules and ultimately the risk of upsetting a customer and losing business.

In-house industrial 3D printer

Industrial 3D printers are costly, heavy-duty and not generally suitable for local office environments (ie. near where you sit). More importantly, they can require costly maintenance and are not always easy to operate. In addition to buying the printer, you may need to hire a full-time technician who does the printing, and therefore they’re most commonly used in the format of an in-house service bureau – which has similar pain points as external service providers.

Moreover, you’re essentially losing money if you are only running it at half-capacity. The cost of materials, maintenance, and operator does not justify occasional usage, so you have to keep churning out part after part to justify the large investment.

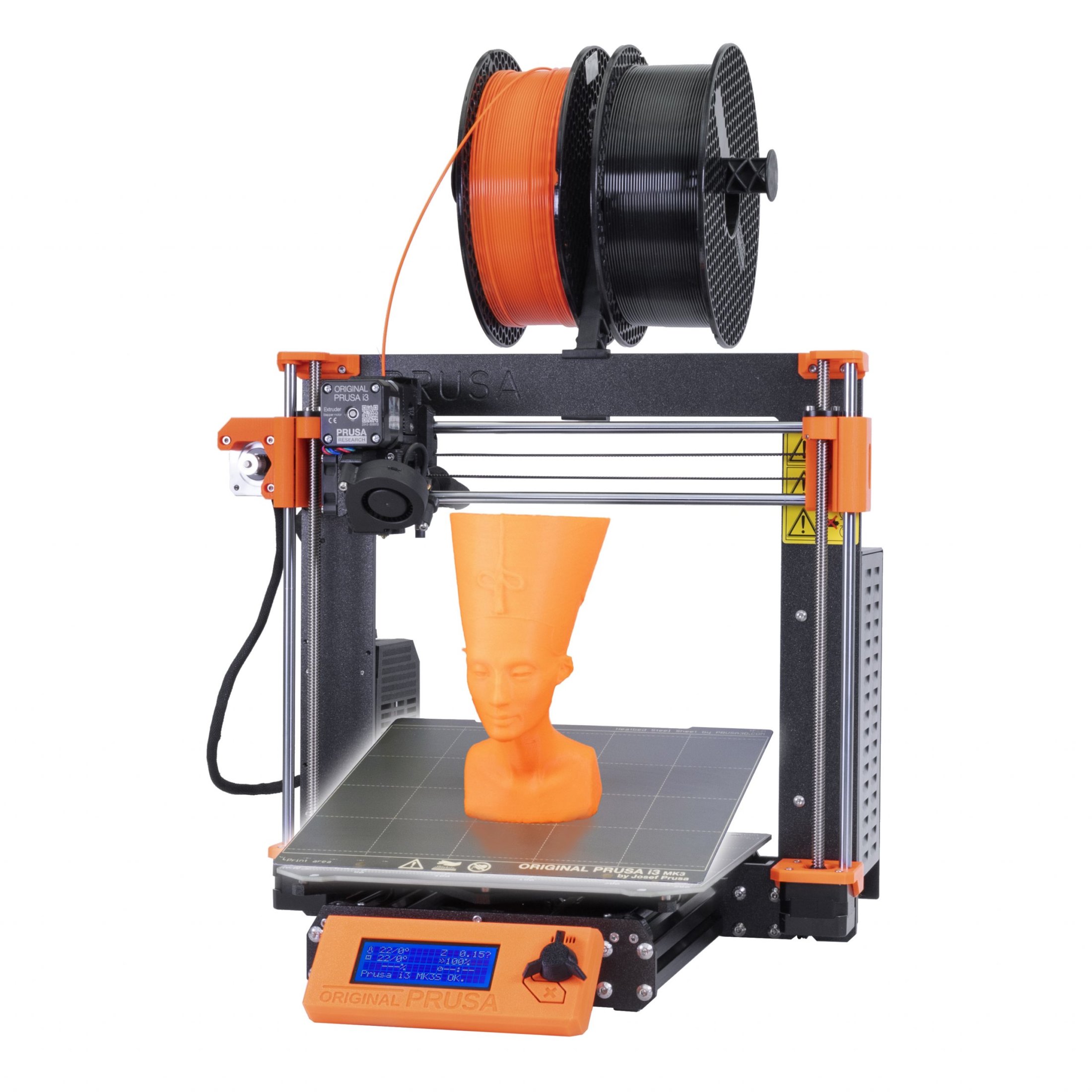

Hobbyist 3D printers

Some engineers or companies that do not have enough resources to buy an industrial 3D printer, rely on cheaper hobbyist 3D printers. These 3D printers can be a good starting point for the technology, but not always. They are targeted at consumers who are price sensitive, and the low price tags are often reflective of lower build quality.

They often rely on 3rd-party software packages to operate, and operation often requires quite a lot of fine tuning. That said, if you have your own 3D printer and you have successfully gone through the tuning you could have a decent experience… as long as you’re the only one using it. Because of the manual tuning, once more than one user steps in the workflows can quickly head downhill. Customer support can be challenging if available at all, and materials will require experimentation to figure out what does or doesn’t work.

What to Look for when Buying a Professional Desktop 3D Printer

So, you may ask that if you cannot use hobbyist 3D printers or even outsource the 3D printing job, then what is the ideal way to proceed? We propose you consider buying a professional desktop 3D printer that can give you exceptional results. Below are some of the main things to look for in a professional desktop 3D printer:

Proprietary Technology

While this is becoming less common as patents expire, it is still something to consider. There are a surprising number of professional desktop 3D printers that use the exact same technologies and components as their hobbyist counterparts which begs the question – why would someone pay a professional price for something that is undifferentiated?

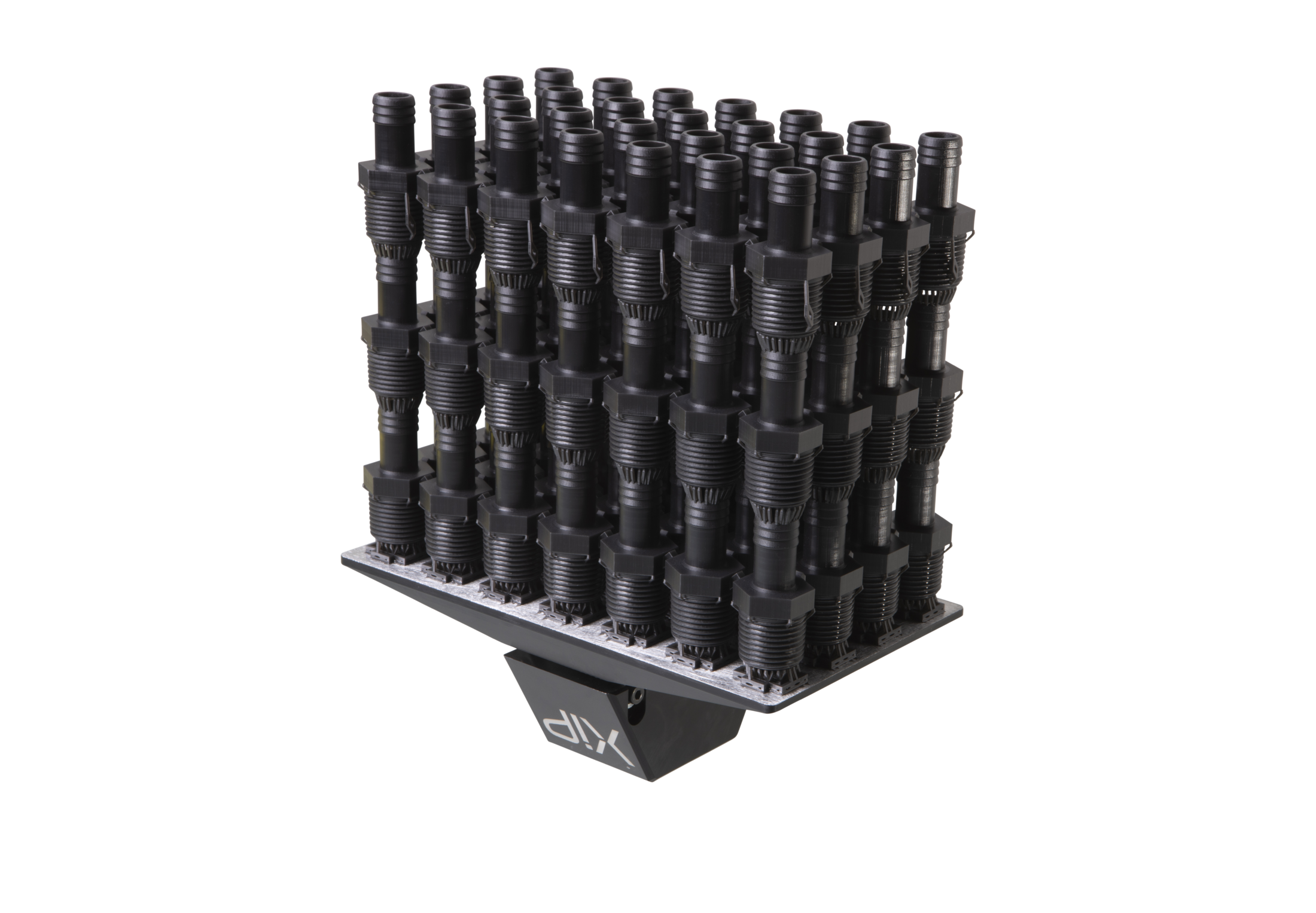

Nexa3D’s XiP is an example of a printer that has some serious innovation under the hood – taking advantage of the LSPc light engine and membrane that powers its industrial brethren the NXE 400Pro Industrial 3D Printer.

Build Quality

Professional desktop 3D printers should be built to last and provide higher throughput than alternatives. While many 3D printers are built with plastics and acrylic, consider looking for something that has metal construction for added rigidity and longevity. If you have a chance to see them in person (at a tradeshow for example) don’t be afraid to walk up and open the door. That can tell you a lot about the rigidity (or flimsiness) of the printer.

XiP from Nexa3D is built almost entirely out of aluminum with a full aluminum body and a machined aluminum vat frame. The z-axis is anchored from top to bottom unlike most resin 3D printers which drastically reduces vibration during printing and leads to better part quality.

Validated Materials AND Open Materials

Your 3D printer is only going to be as good as the materials you use so choose wisely. The debate of open vs closed systems has raged since the beginning of desktop 3D printers, but at the end of the day isn’t it best to have options and flexibility? Some professional desktop 3D printers give you one option only – buy and use their materials. Others have more flexibility with validated materials AND the option to use 3rd party materials.

XiP offers both so you can have an easy controlled experience or switch to a 3rd party material that you already have. Make sure there is a selection of materials with a variety of properties to fit your application needs too.

Quantity while maintaining Quality

You don’t have to compromise on quantity to maintain the quality of each part you print. While older technologies like FDM and SLA, may only print a single decent sized print per day, professional desktop 3D printers like Nexa3D’s XiP, could allow for 4-8 decent sized prints per day or several assemblies. And this is without any quality compromise and this is just incredible.

Throughput & Speed

3D printers that deliver value should also be judged on their throughput and speed. With professional desktop 3D printers, you can achieve high throughput and speed while maintaining the quality of the product.

For example, the XiP 3D printer allows users to print at blazing speeds of up to 18 cm per hour. It is 6 times faster than competing SLA printers.

What’s Next?

This professional desktop 3D printer buyer’s guide will have hopefully helped you to better understand the reasons that professional desktop 3D printers exist, and what to look for when purchasing one. Professional desktop 3D printers will often be a good option for users who want to be hands-on with their 3D printer for maximum access, but also want a higher end experience with improved performance and reliability.

If you’re still not quite sure if a professional desktop 3D printer is right for your application you can always contact the Nexa3D sales team for a no-pressure consultation to understand if a Nexa3D printer is a good fit for your application or not. Want to get a sample? We’ve got those too – get xRook.