- Metal 3D Printing Guide: What It Is & How It Works [2024] - February 5, 2024

- Metal Injection Molding: What It Is & Top Alternatives [2024] - January 11, 2024

- 11 Fastest 3D Printers on the Market (Industrial and Desktop) [2023] - December 11, 2023

Dental 3D printers have helped the dental industry create complex, custom dental prosthetics and appliances in a highly accurate and repeatable process.

Many industries have benefited from advances in 3D printing technology, with the dental industry being one of the most prominent use cases for 3D printing. The ability to manufacture precise implants, bridges, crowns, and other orthodontic devices has improved workflow efficiency for dental labs so they can respond to the rising demand.

This guide will explore the various 3D printing technologies ideal for printing dental parts and the best dental 3D printers on the market.

How are dental parts 3D printed?

When 3D printing dental parts, the process typically begins with creating a 3D digital model using specialized Computer-aided designs (CAD) software.

The CAD software obtains data from scans or impressions of patients, which are then used to create a 3D digital model of the dental part. This is then sent to a 3D slicer which converts the 3D model into a format a dental 3D printer can understand. The 3D printer builds the object layer by layer, each fused or cured, depending on the specific technology used.

Sometimes, the printed part may require post-processing, such as polishing and finishing, to get the desired finish. Once the part is complete, the patient receives a perfectly fitting dental device, such as crowns, bridges, and implants.

3D Printing Technology for Dental Applications

Some of the most common technologies used for 3D printing dental parts include:

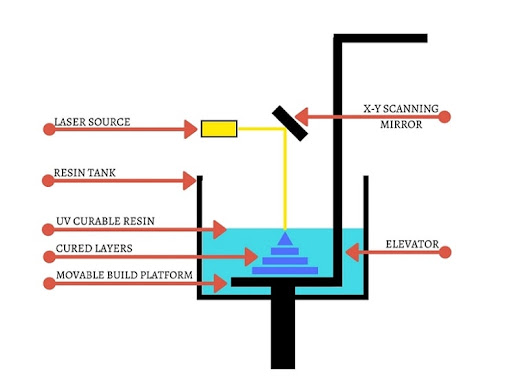

Stereolithography (SLA)

Stereolithography is a 3D printing technology that uses a laser to cure photosensitive materials layer by layer to create solid parts. This resin 3D process is ideal for creating precise, highly-detailed prototypes requiring watertight tolerances and smooth surfaces like molds, guides, and trays.

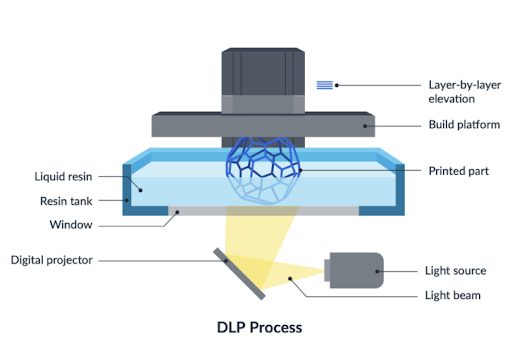

Digital Light Processing (DLP)

Digital Light Processing (DLP) is another generation of SLA 3D printing that uses liquid resin and projector or an LCD screen. The projector flashes an image of an entire cross-section of the object that is cured when exposed to ultraviolet light.

DLP 3D printing technology works well for printing dental parts because it also produces highly detailed and accurate parts with smooth surface finish. DLP technology works faster than traditional Stereolithography technology because it uses light to harden the entire layer rather than line by line.

However, Digital Light Processing does not accurately solve the classic speed vs. quality issues existing in the predecessor SLA 3D printers. Another potential challenge with DLP is that its single projection source means that the image can become distorted, which can lead to uneven build quality.

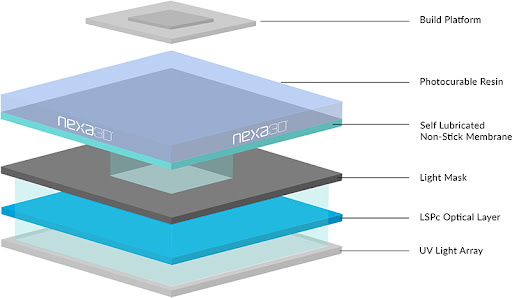

mSLA

Nexa3D’s LSPc ® technology

mSLA, or Masked Stereolithography, is a later generation of stereolithography that uses an LED array light source instead of a laser or a single projection point. The LED array projects light through an LCD panel which masks certain pixels while printing so curing occurs only in the unmasked section.

mSLA is one of the fastest 3D printing technologies that can also maintain print quality for even the most intricate geometries. However, Nexa3D’s proprietary version of mSLA technology–Lubricant Sublayer Photo-curing or LSPc®–goes a step further. This technology combines a UV light array and LSPc® Optical lens layer to ensure light uniformity in this process, which is essential for optimal use of LSPc® High Contrast Mask.

The LSPc® HC Mask is in charge of projecting 3D image slices onto the vat, where the photopolymerization process takes place layer by layer. This provides the fastest printer on the market with the largest build area in its class without sacrificing image quality: you get high edge-to-edge performance with no distortion, in contrast to DLP 3D printers.

Nexa3D’s LSPc® technology also utilizes a patented lubricated sublayer called the Everlast 2 membrane. This membrane significantly reduces the “peel force” imposed as each layer is lifted off of the base of the 3D printer vat–allowing for significantly faster print jobs and more complex geometries with fewer supports.

Best Dental 3D Printers

1. Nexa3D NXE 400Pro

Nexa3D NXE 400Pro is ideal for both industrial and dental applications, and it comes with an exceptional 17L build volume and ultrafast speeds without compromising accuracy or repeatability. It uses Nexa3D’s patented Lubricant Sublayer Photo-curing (LSPc®) technology that delivers accuracy with a superior surface finish.

NXE 400Pro industrial resin 3D printers offer a wide range of materials to meet performance needs — including polypropylene, acrylonitrile butadiene styrene, and other engineering-grade functional materials.

Various manufacturers use Nexa3D NXE 400Pro for their production needs. Murtfeldt Additive Solution GmBH, a full-service production company, uses NXE 400Pro to produce specific, high-quality electrical connectors. These high-precision products require an excellent surface finish to be effective, and the NXE 400Pro was the only 3D printer capable of the job.

Pros:

- Unmatched 17-liter build volume (274 x 155 x 400mm).

- Best in its class for print speeds (6.5x faster than other SLA and DLP technology).

- LSPc® light engine delivers uniform, high power, and distortion-free image to ensure part-to-part accuracy and uniformity.

- Self-lubricated membrane prevents delamination forces and enables fast print speeds.

Cons:

- This is also a professional printer (not for hobbyists).

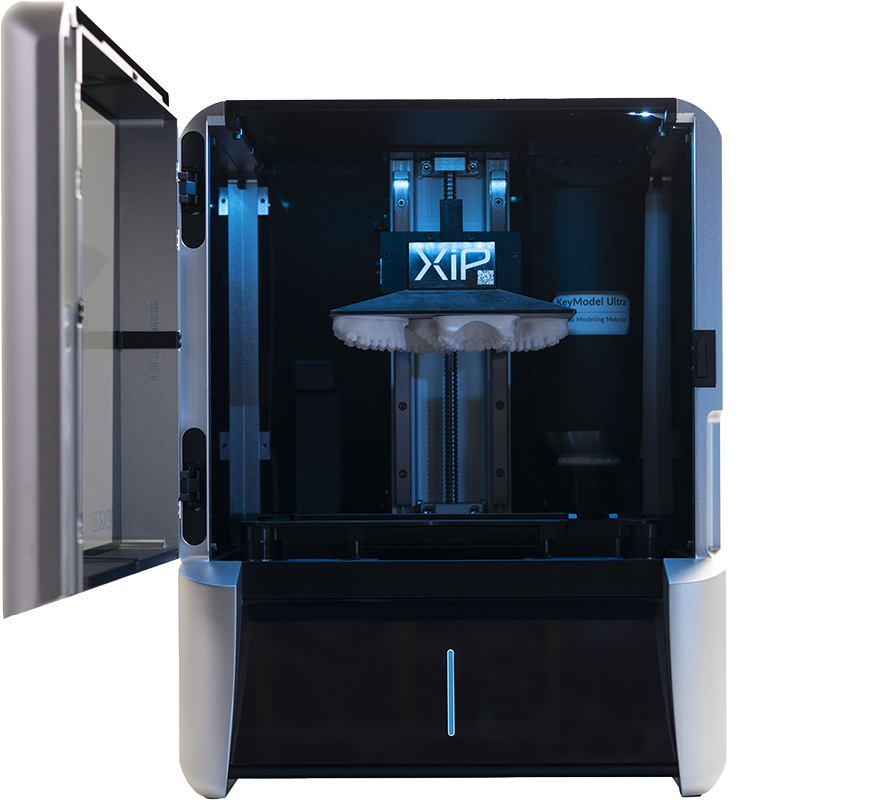

2. Nexa3D XiP

The Nexa3D XiP is a great option for dental professionals seeking an affordable and user-friendly desktop 3D printer. The XiP also uses LSPc® technology to achieve ultra-fast printing speeds. It combines a compact footprint with a 4.8L print volume to deliver high-quality prototypes on your desktop.

The XiP offers a broad range of already validated rigid and elastomeric materials, as well as a fully open material platform providing ultimate flexibility and access to the materials you need, when you need them.

For dental professionals looking for high-precision capabilities in a desktop size, the XiP is a perfect solution.

Pros:

- Speed: Print 10 dental models in 30 minutes

- Large 4.8L build volume

- Easily upgradeable and easy to operate.

- Affordable and user-friendly.

- Open material platform (allowing third-party resins).

- Open material platform (allowing third-party resins).

- Wide variety of dental resins available

Cons:

- Its build volume is smaller than the NXD.

Request a free XiP sample part.

3. XiP Pro

\

\

Nexa3D XiP Pro is an industrial resin 3D printer that delivers the highest production throughput at the lowest cost of operation. XiP Pro offers the largest 19.5L build volume and fastest print speed in its class–and its unrivaled productivity allows you to produce functional prototypes and final-use parts at previously unattainable production economics.

Various industries use XiP Pro printers for their manufacturing needs. According to Glen Mason, Manager of Advanced Innovation/Industrialization at DeMarini (a division of Wilson Sporting Goods), “XiP Pro gives us about 10x the throughput of what we had before. Nexa3D has done a really great job taking the costs out of 3D printing while increasing the capacity. Their printers are getting bigger, faster, and more affordable at the same time. It’s a total win for the users.”

Pros:

- Large industrial capacity and compact footprint

- Intuitive NexaX Software & Smart Resin Delivery System

- Environmental Monitoring System

- 19.5L build volume & 10″ High-Resolution LCD Touchscreen

- LCD-based VAT photopolymerization process uses patented Lubricant Sublayer Photocuring (LSPc) technology

- Self-lubricating membrane enables lighting-fast print speed and unprecedented production value without sacrificing print quality or surface finish

- 7K resolution LCD screen with 46 µm pixel size and 23 µm sub-pixel resolution

- Open material platform (ability to use with third-party resins)

Cons:

- Not for hobbyist 3D printing

Get a free XiP Pro sample part

4. Form 3B+

Formlabs Form 3B+ is a professional 3D printer that uses Low Force Stereolithography (LFS)™ technology. This device has a build volume of 145 × 145 × 185 mm and supports biocompatible materials, making it suitable for dental 3D printing. Form 3B+ has a physical dimension of 405 × 375 × 530 mm and weighs 17.5 kg.

Pros:

- Form 3B+ uses SLA 3D printing technology.

- Offers good print quality and an optimized workflow.

- Relatively affordable.

Cons:

- It has a 483-minute build time, which is slower than other leading 3D printers.

- It has a closed platform that requires Formlabs branded resin.

- Form 3B+ has a relatively small build volume of 3.8 liters.

Also Read: Form 3B+ vs Nexa3D XiP

5. Stratasys J700 Dental

Stratasys J700 Dental is a dental 3D printer that uses material jetting (UV-cured) technology to produce thermoset parts using resin feedstock. This device measures 490 x 390 mm (19.3 x 15.35 in.), weighs 430 kg, and has an automated workflow for managing the additive manufacturing process from start to end. The printer also has GrabCAD management software.

Pros:

- 490 × 390 × 200 mm build volume.

- Supports various dual materials (such as rigid and soft materials) for printing dental parts.

- Has an automated load/unload function to produce various models.

Cons:

- Expensive compared to other 3D printers.

- Unsuitable for smaller projects.

- Build time can be slower than other 3D printers.

6. Carbon M2

The Carbon M2 is a professional dental 3D printer that uses Digital Light Synthesis (DLS) technology to produce parts. The printer has a build volume of 189 x 118 x 326 mm and physical dimensions of 540 x 654 x 1734 mm. It supports various materials, such as dental PS, PA11, and other resins.

Pros:

- It comes with an automated print setup, which simplifies the entire printing process.

- It has a faster print speed.

Cons:

- The Carbon M2 has a relatively small build volume compared to other 3D printers.

- It is also more expensive than most dental 3D printers.

7. 3D Systems NextDent 5100

The 3D Systems NextDent 5100 is an industrial dental 3D printer that uses material jetting (inkjet) technology for the production of dental appliances and sacrificial castings. The printer runs on the Figure 4® technology and has a build volume of 124.8 x 70.2 x 196 mm.

NextDent’s 3D printing materials are biocompatible and CE certified in accordance with Medical Device Directive 93/42/EEC, listed at FDA, and registered in various other countries.

Pros:

- It has a fast print speed.

- The printer has an enclosed system that is dust-free for printing precision parts.

Cons:

- It’s unsuitable for larger projects due to its small build volume.

- It has a closed material platform and accommodates only NextDent 3D printing materials.

8. Kulzer Cara Print 4.0

The Kulzer Cara Print 4.0 is a professional dental 3D printer that uses Direct Light Processing (DLP) technology to produce parts. The printer has a build volume of 103 x 58 x 130 mm and supports various dental materials, such as zirconium dioxide and gypsum. The 3D printer has an average print speed and uses a cara Print CAM 2.0.

Pros:

- Kulzer Cara Print 4.0 is lightweight, weighing about 21 kg.

- It is user-friendly and easy to operate.

Cons:

- The Kulzer Cara Print 4.0 is expensive compared to other dental 3D printers on the market.

- It uses DLP printing technology, which is not as advanced as mSLA 3D printing.

9. Rapid Shape D100

Rapid Shape D100 is an industrial dental 3D printer that uses Direct Light Processing (DLP) technology to produce parts. The device has a build volume of 338 x 190 x 80 mm and supports various materials, such as nylon, PMMA, PEKK, and PEEK. The D100 also comes with in-built software for controlling the entire printing process.

Pros:

- The Rapid Shape D100 has a large build volume, which is ideal for printing large parts.

- It supports multiple materials and allows users to customize their prints.

Cons:

- The Rapid Shape D100 is expensive compared to other 3D printers.

- It has a relatively slow print speed.

- It also uses DLP printing technology.

How to choose the best dental 3D printer

Choosing the best 3D printer for printing dental parts depends on various factors, such as budget, print speed, and materials compatibility.

3D Technology

The most common 3D printing technologies used are Masked Stereolithography, Material Jetting, and Digital Light Processing (DLP). Each of these technologies can result in different dental end-products.

Nexa3D’s resin 3D printers use a proprietary version of mSLA technology called Lubricant Sublayer Photocuring (LSPc®), which combines the LSPc Optical lens layer and a UV light array to ensure light uniformity. This makes it perfect for a broader range of industries, including dentistry, manufacturing, automotive, and jewelry.

Accuracy and precision

With the right 3D printer, users can print parts with high accuracy. Professional dental 3D printers that use mSLA or material jetting technologies are often more accurate than those that use other technologies, such as FDM or DLP.

Ease of use

A user-friendly 3D printer means engineers can quickly understand the device and ramp up production. Look for a 3D printer with an intuitive interface, clear instructions, helpful tutorials, and a great customer service team.

Throughput and speed

The fastest 3D printers can help reduce the time it takes to print dental parts, resulting in a quicker time to market and greater dental workflow efficiency. For example, Key Dental Technologies can print 20 Ortho Models in 30 minutes thanks to Nexa3D printers.

Material requirements

Different 3D printers support different material types–and some only allow for their branded materials. Look for a 3D printer that has an open material platform and is compatible with a range of materials, such as xMODEL 2505, KeyOrtho IBT, and KeySplint Soft®.

Cost and ROI

It’s important to consider the return on investment of a 3D printer and its consumables to ensure it offers a good long-term value. If you’re investing too much on the initial purchase, it is more advisable to switch to more cost-effective options.

For example, Excel Orthodontic Lab switched from the Carbon M2 printers to the more cost-effective Nexa3D 3D printers. Carbon does not sell its 3D printers but rather leases them for 3 years at a minimum of $150,000–upon which time the customer must return the hardware or start a new lease.

Use the best dental 3D printer

Nexa3D offers an array of advanced 3D printers that are ideal for printing various parts and cuts across several industries. In addition to offering excellent accuracy and precision, these 3D printers have an intuitive interface, a wide range of compatible materials, and high throughput.

Whether you’re using the XiP series or NXE 400Pro, Nexa3D printers offers world-class dental model manufacturing capabilities at ultrafast speeds. The XiP Pro’s unrivaled productivity and accuracy means dental and orthodontic companies can make dental resin models, splints, impression trays, occlusal night guards, and more– with the speed and quality their patients need.

With Nexa3D’s advanced technology, dental labs can now produce professional-grade models at a fraction of the time and cost of other 3D printers.