- Everything you need to know about ABS 3D printing - March 9, 2023

- How a New Generation of 3D Printers is Accelerating the NPD Process - November 16, 2022

- Buyer’s Guide to an Industrial 3D Printer - October 31, 2022

The Author, Stelios Avraam is a mechanical design engineer and co-founder of Simlead a product design, strategy, and innovation agency based in Strovolos, Nicosia in Cyprus.

In today’s highly competitive environment, organizations need to have agility to adapt quickly to market changes. Every day, hundreds or thousands of products are launched in international markets and companies are pushed more and more to shorten project completion cycle time in order to stay ahead of the competition. In a nutshell, there is a lot at stake to ensure your product can be the first to make the difference, gain greater market share, and create a positive impact on users.

What is the NPD Process?

The process of turning an idea into a tangible product is known as the New Product Development (NPD) process. The NPD process is a systematic approach for organizations that assist them in developing high quality user centered products that have the highest chance of succeeding in such crowded and oversaturated competitive markets. NPD is an iterative process, therefore the more you can understand your users and articulate your thoughts clearly, the more successful your solutions will be. The NPD process can be divided into the following phases:

Phases of the New Product Development (NPD) Process

- Discovery: The first phase is all about defining goals, vision and project expectations. Main activities of the discovery phase are:

- Research

- Exploring markets and technological trends

- Innovation strategies

- Product strategy

- User journey

- Brand directions

- Design: During the design phase, any ideas, insights and opportunities are turning into tangible concepts. This iterative process allows for the full exploration of concepts and alternatives, while involving all stakeholders in critical decisions regarding concept directions.

- Development: In this phase, design intent meets engineering expertise. The manufacturing know-how ensures that the design integrity, functionality and performance remain intact throughout the development process. Highly detailed physical prototypes are produced and tested extensively with targeted user groups to get hands-on experience with the product as well as to obtain vital information and feedback.

- Delivery: In the delivery phase, technical drawings and specifications are transferred into manufacturing processes and quality procedures.

Prototyping the MVP

The NPD process has grown increasingly stressful in recent years with businesses applying increasing pressure to product release timelines. The most challenging part of the process, which is taking place during the development phase, concerns rapid development of functional prototypes, known as minimum viable product (MVP). The NPD process relies heavily on the prototyping step, since critical feedback is given by the users to the development team, therefore major improvements happen. This ability to continuously evaluate, demonstrate and modify the design until its highest quality level is achieved, is the key to reducing product errors and risks.

However, companies are forced to threaten product success by carrying out fewer prototypes and testing cycles due to the time-consuming and expensive prototyping process. Fabricating highly complex prototypes at high speeds while mitigating risks has always been a priority for designers and engineers but that can conflict with the tight timeline pressure from above. Based on the product’s complexity, the NPD process may be time-consuming and if executed improperly, most probably will lead the under-development product out of the targeted market.

Solving the NPD Crunch with Next-Gen Ultrafast 3D Printers

With the advent of the next generation of 3D printers – such as the XiP from Nexa3D – one can test, evaluate, and get feedback immediately on a number of new enhanced iterations of the product all within a single day. Unlike traditional 3D printing processes, where iteration cycles can take days or even weeks due to slow processes, new generation 3D printers speed up the prototyping step, keep teams focused, saving engineers time, money and resources.

The major characteristics of such 3D printers are: high speed and throughput, as well as a high-quality surface finish. Moreover, under this new generation of 3D printers, a broad range of materials are able to build reliable, functional prototypes that can be leveraged to provide accurate results. These materials allow their utilization to create final products for industries including the automotive, manufacturing, dental and medical.

Design Sprints with Ultrafast 3D Printers

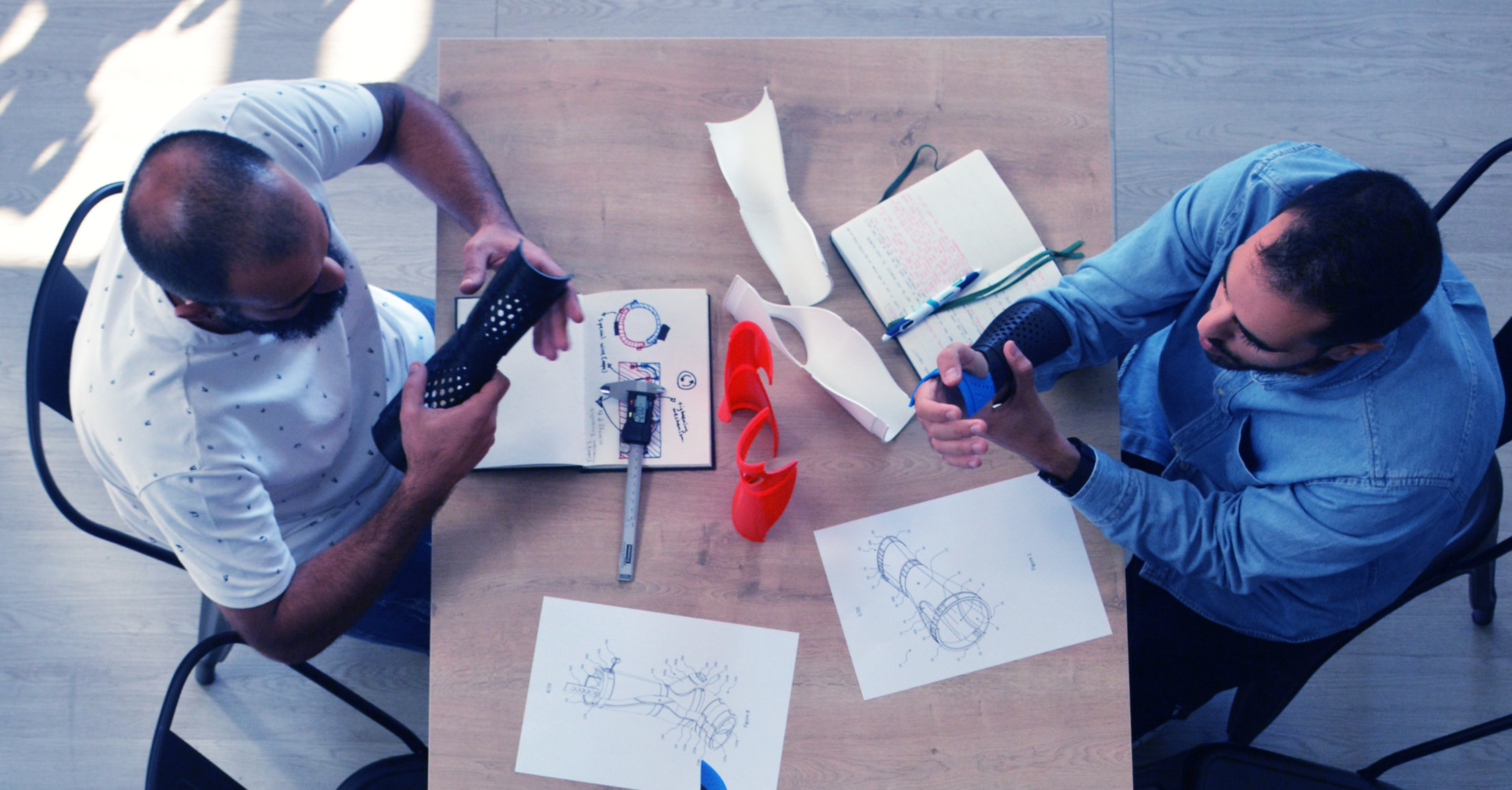

Our company, Simlead, a product design, strategy and innovation agency, is currently implementing this technology during design sprints. A product design sprint (PDS) is a series of workshops aimed at developing a new product or improving an existing one in just four days.

The Four-Day Design Sprint

- Day 1 – Understand, Align, Sketch

- Define the challenges

- Produce a mass of solutions

- Day 2 – Decide, Storyboard

- Curate and vote on best solutions

- Define the prototype with a storyboard

- Day 3 – Prototype

- Build the prototype

- Set up the user tests

- Day 4 – User Testing

- Test the prototype with real users

- Use feedback from the testing to create clear next steps

PDS is the most effective technique to check if a value proposition is correct. The third day of the Design Sprint is dedicated to prototyping. In the case that the prototype needs to be a physical product, the fabrication of a prototype under such advanced technology accelerates the fabrication process, enhances its quality and provides us the opportunity to optimize the overall user experience during the testing day.

That concludes our guide to the NPD process. Hopefully you feel inspired around the new ERA of 3D printers, and have picked up some actionable strategies and techniques you can employ during your next product development process.

If you enjoyed this article feel free to contact Simlead for design consultation and Nexa3D for those interested in ultrafast 3D printing.