Automotive

Our 3D printer for automotive parts lets you go from concept car to 20X faster! In the highly-competitive auto industry, marketplace advantage can only come from greater innovation. Requiring faster design iteration to drive new products. Automotive designers and manufacturing engineer

If you and your team want to:

- Get to market faster

- Cut costs

- Optimize innovation

- Leverage flexible toolless manufacturing capabilities

- Work with new gen of functional materials

- Enjoy seamless transitions throughout your entire product life cycle

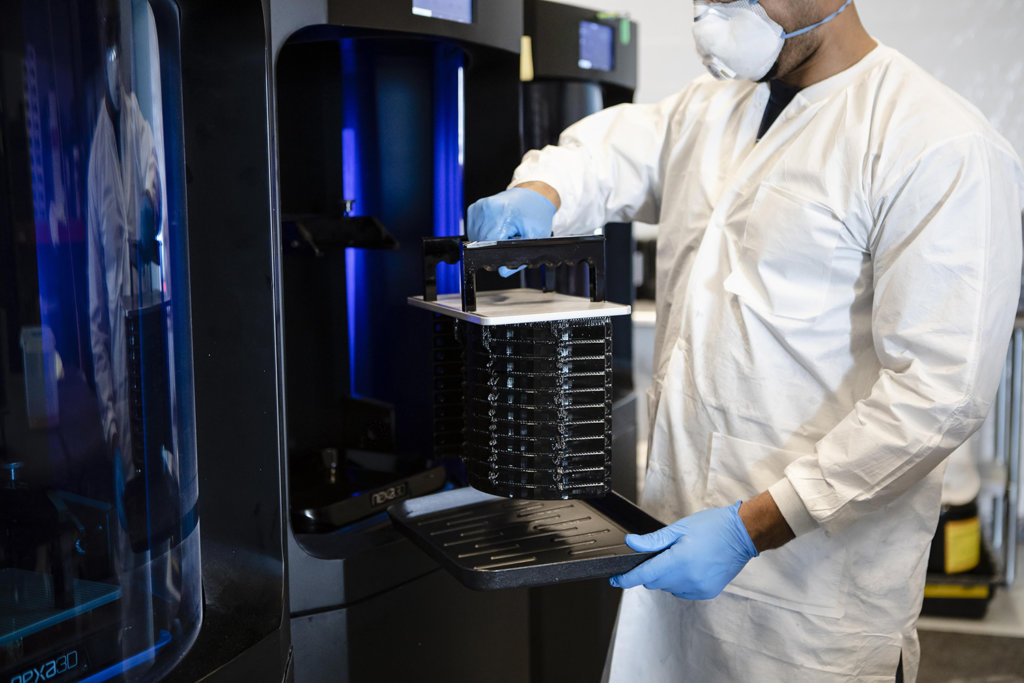

NXE 400Pro 3D printer technology can help!

Our 3D printer for auto parts shortens time to market, reduces cost, and increases innovation with same day prototyping and next day production! With our technology, you’ll own your entire product life cycle and supply chain and enjoy:

- Compressed product development cycles

- Reduced overall R&D costs

- Shorter production lead times

- Flexible manufacturing at scale

- No tooling costs

- Just in time prototypes and production part

Boost your R&D and Manufacturing Productivity by a Factor of 20!

Our 3D printing for automotive parts allows for better control of the entire product development and manufacturing process and the ability to move quickly on iterations. It boosts productivity by 20X and fundamentally simplifies the 3D printing process, resulting in:

- Greater productivity

- Quicker responses to market changes

- Better control of processes

- Digitized inventory

- Seamless transition from prototyping to production — on the same printer!

Reduce Development Time

In addition to rapid prototyping, our 3D printer for auto parts enables true design optimization by reducing prototype development time by 6X. Larger prototypes can be realized with 2.5X larger build volume, and product development can transition from prototyping to low-scale production, all on the same printer!

Explore NXE 400Pro

Our Circular Economy Design Principles Mean a Better Bottom Line!

Our 3D printer for car parts leverages circular economy principles in every phase of the design and delivery process by rigorously measuring and improving on what matters:

- Minimizing process waste

- Reducing energy consumption per part

- Working with our customers to reduce their overall carbon footprint

- Making it possible to produce parts on-site and on demand, reducing carbon footprint

- Optimizing parts for lightweighting, parts combination, and reduction of power consumption per part through our Digital Twin Software