High Speed Extrusion 3D Printer

The HSE 180 series High Speed Extrusion 3D Printing Platform operates at a remarkable five to 15 times the speed of its competitors, aiming to revolutionize the manufacturing landscape. Featuring an X-Y stage equipped with linear servo motors, this advanced 3D printer addresses longstanding challenges in additive manufacturing, specifically tackling issues related to strength, speed, and scalability that have traditionally constrained the industry.

Unmatched Speed

Achieve printing speeds of up to 500 mm/sec utilizing linear servo motors, boasting impressive 1G acceleration, and a swift 1 m/sec travel speed.

Large Build Volume

Efficiently produce substantial components with rapid speed and robustness on a generously sized build plate that accommodates 85% of the world’s jigs and fixtures.

Open Ecosystem

Select the ideal material for your application from our extensive material portfolio or explore alternatives to ensure optimal performance with your filament choice.

Specifications

| Print Heads | One |

| Nozzle | Hozzle™ heated nozzle |

| Filament Diameter | 1.75 mm |

| Nozzle Diameters | 0.4, 0.8 mm |

| Build Volume | 690 x 500 x 600 mm |

| Motion System Accuracy | 0.081 mm XY and 0.005 mm Z |

| Electrical Requirements | 4 KVA, 220/240V 20A for LT machine and 40A for ST and HT machines, Single Phase 50/60 Hz |

| Net Weight | 850 kg |

| Printer Dimension | 1590 x 1350 x 2490 mm |

HSE 180 3D Printer Models

HSE 180LT

Low-Temperature Materials

Key Industries:

- Biomedical Device

- Commercial Manufacturing

- Footwear and Apparel

- Architecture and Design

Key Applications:

- Prosthetic Sockets

- Orthotic Devices

- Low-Temp Jigs and Fixtures

- Rapid Prototyping

- Castings

HSE 180ST

Standard Materials

Key Industries:

- Automotive and Transportation

- Consumer Goods

- Electronic Manufacturing Services

Key Applications:

- Low-Temp Jigs and Fixtures

- Low-Pressure Mold Tooling

- NPI and Bridge-to-Production

- Manufacturing Aids

HSE 180HT

High-Temperature Materials

Key Industries:

- Aerospace and Defense

- Semiconductor Device Manufacturing

- Oil and Gas

Key Applications:

- High-Pressure Mold Tooling

- High-Temp Jigs and Fixtures

- Connectors

- Functional Parts

Innovating the Additive Manufacturing Landscape

Traditionally, extrusion 3D printing methods such as FFF and FDM have been characterized by painstakingly slow processes, requiring hours for simple geometries and days for intricate designs. Our HSE technology revolutionizes this by minimizing wasted movement through linear servo motors, boasting 1G acceleration, and a rapid 1 m/sec movement speed. This breakthrough enables manufacturers to achieve printing speeds five to 15 times faster than conventional FFF and FDM printers.

The synergy of our HSE technology and its extensive range of top-quality materials empowers manufacturers to scale 3D printing to match the efficiency of subtractive manufacturing, laying the foundation for the advancements of Industry 4.0.

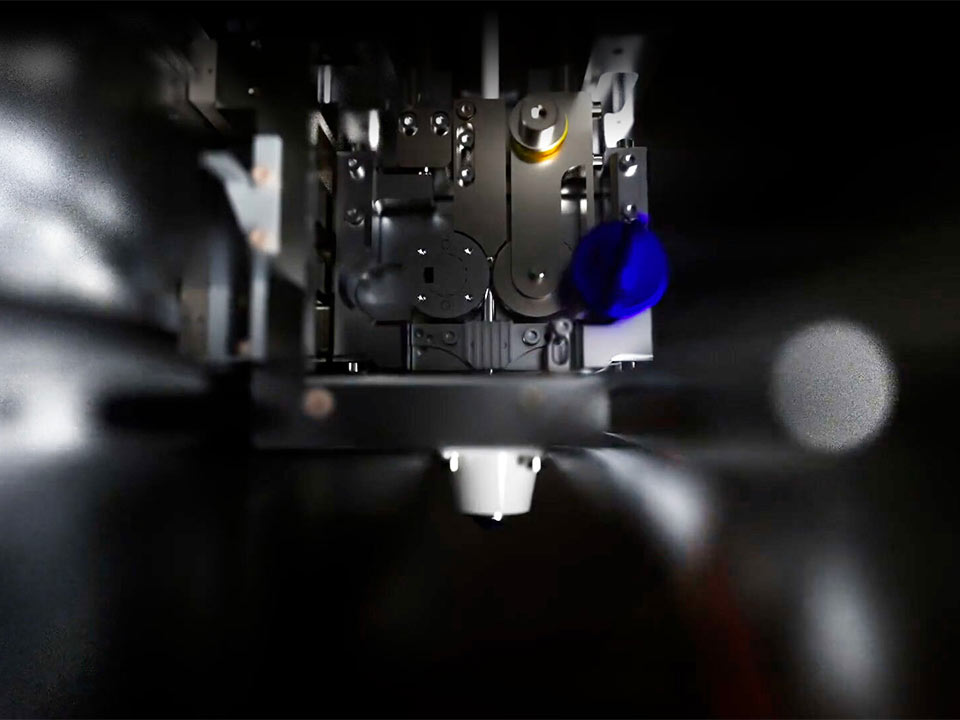

Revolutionizing Extrusion 3D Printing: Hozzle™ Heated Nozzle Technology

Achieving high-speed extrusion of high-performance materials demands an exceptional nozzle. Hozzle™ is an integrated heating and temperature sensing unit that sets new benchmarks with temperatures soaring up to 550°C. Featuring a sapphire tip, the Hozzle heated nozzle empowers manufacturers to effortlessly extrude the most cutting-edge high-performance materials available in the market.