xESD Case Study

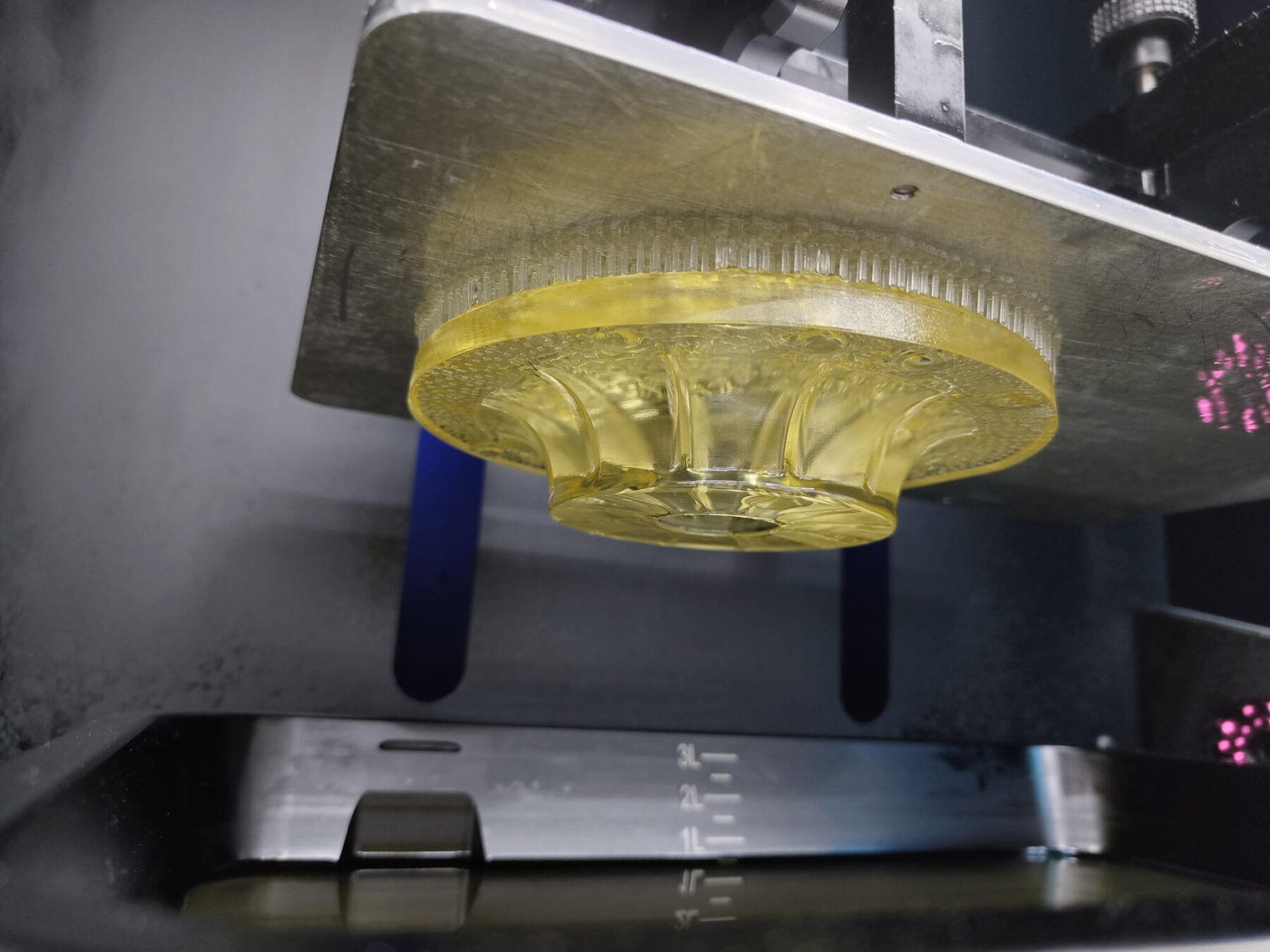

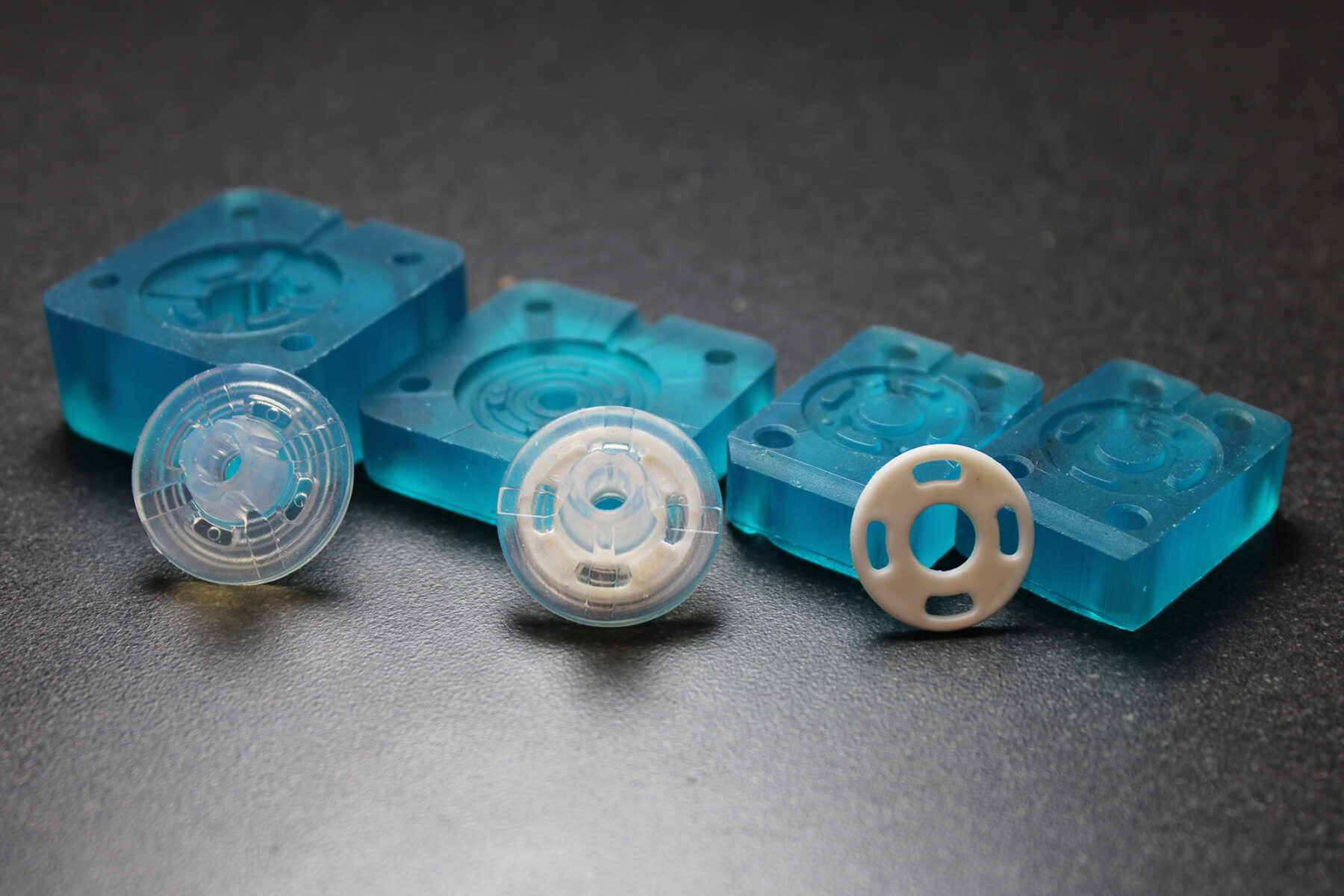

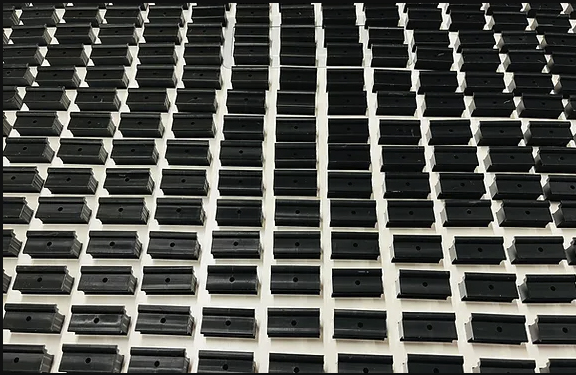

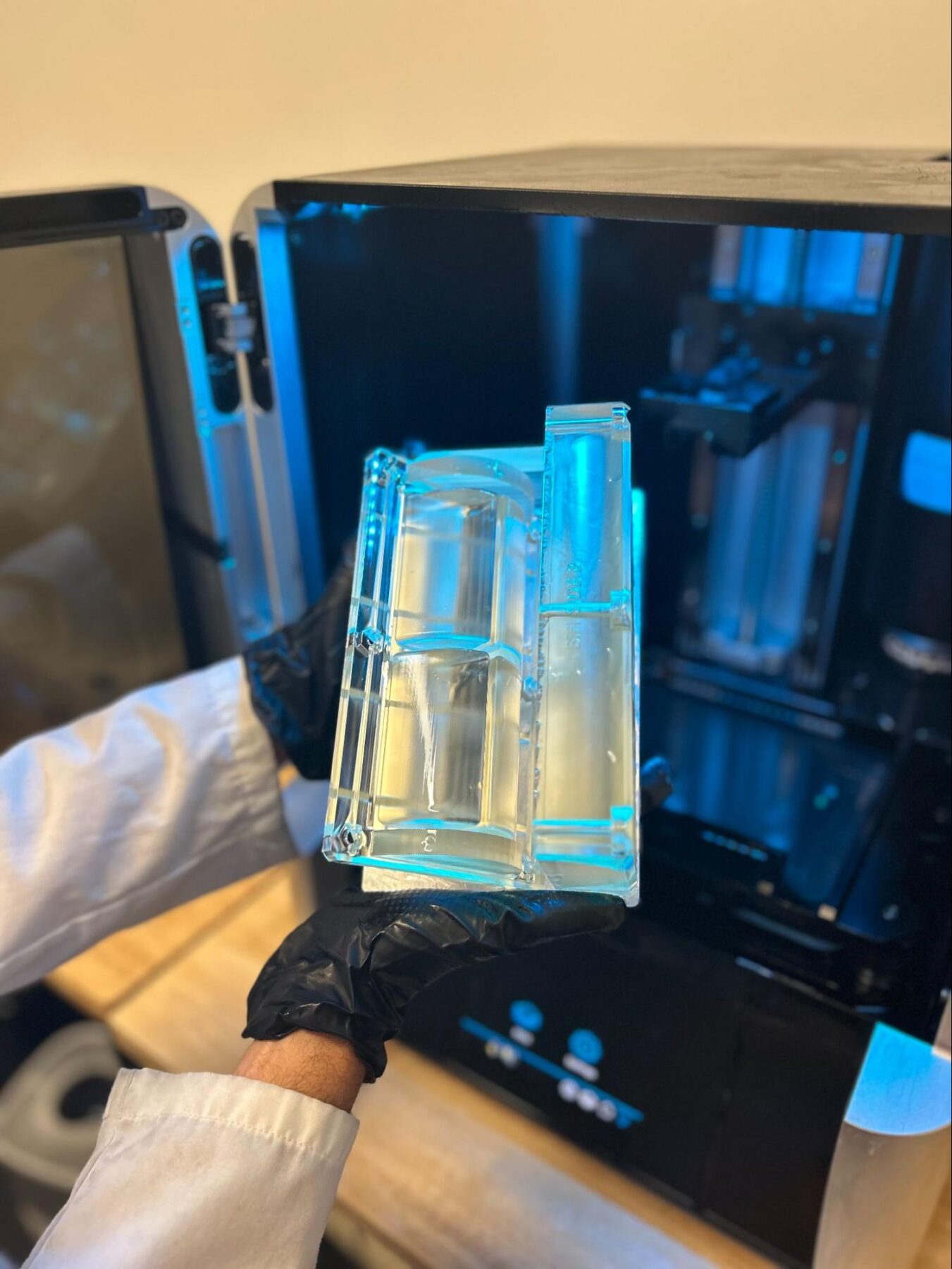

By using xESD resin formulated for ultrafast LSPc 3D printing technology, the customer achieved high resolution, static dissipative performance, and significant cost savings, revolutionizing their production process for faster turnaround times and improved precision.

View Case Study