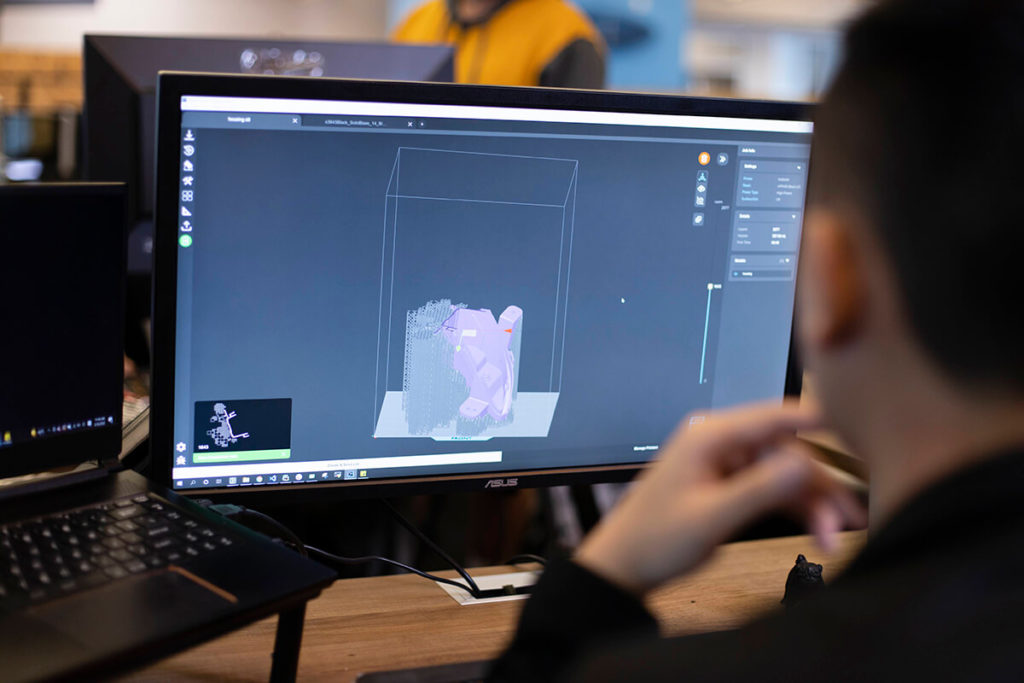

NexaX 3D Printing Software

Intelligent and Automated Print Preparation and 3D Printer Management Software For Optimal Efficiency

NexaX software enables process stability and print consistency, making it easy to scale from prototyping to full scale production.

Raise the ante of the entire design-to-manufacturing 3D printing cycle. Through the interplay of hardware, software and chemistry, NexaX 3D printing software offers print preparation and 3D printer management software with API integration for other software to unlock new properties for printed parts while enabling process stability, production scaling, consistent product quality, higher yields and unmatched mechanical performance.

Lightning Fast Proprietary Algorithms

With lightning-fast proprietary slice algorithms and automatic support generation, NexaX 3D printer software combines process and geometry algorithms with end-to-end workflows to optimize parts production.

Seamless Integration

NexaX provides APIs that make the integration of a variety of software tools easy, including assembly parts consolidation, generative design for AM, lightweighting, automated print optimization, part costing estimator, ROI calculator and MES workflow.

What’s New in Windows Version 3.0

Improved Account Management

- By creating a Nexa3D account, users can now access printer details, print history, and data associated with print jobs.

- Leverage remote accessibility to check their print progress, analytics, and job history without having to be next to the printer.

NEW Dashboard

- Quickly access printer status and details, uptime, utilization, material consumption, print success rate.

- Gain useful insights with print analytics for individual printers or your entire fleet.

- Monitor performance with diagnostics and print history for each print job.

Intelligent Print Queueing

- Streamline your print workflow by sending files directly to available printers after slicing.

- Customize print queues based on material and capacity availability.

- Once a build file is created, users can send files to multiple printers in the fleet.

NexaX 3D printing software comes loaded with significant productivity and performance features

NexaX Basic |

NexaX Pro |

|

|---|---|---|

Orientation and Scaling ToolsAuto-Orientation and Precise Manual Controls |

||

Part ArrayingFill build volume with duplicate parts in X, Y and Z |

||

Validated Resin SettingsPrint resins with manufacturer preset values to achieve known mechanical properties |

||

Customizable, Advanced Support GenerationAuto-generate or customize support for each part with advanced, configurable settings |

||

Intelligent Process ControlsPrint process adapts to part geometry to maximize printability and speed |

||

Mesh Error WarningsFlags common mesh issues that impact printing |

||

Print StatisticsSummary of print time, number of layers, and part volume |

||

Tabbed ApplicationWork on multiple projects at once |

||

Offline Licensing & UsageOperate the ecosystem offline for security or access concerns |

||

Printer Fleet ManagementConnect to printers, queue jobs, and review job history |

||

Hollowing & LatticingMinimize resin usage for large solid parts |

||

Advanced Mesh RepairFixes mesh issues to prevent print failures |

||

XY NestingOptimize the 2-D space on your build platform |

||

Open Material PlatformPrint 3rd party resins and access a full suite of process parameter to customize for any scenario |