High Speed Extrusion 3D Printer

Revolutionize your manufacturing process with the HSE 280i High Speed Extrusion (HSE) 3D Printing Platform, outpacing the competition at speeds ranging from five to 15 times faster. Designed to overhaul factory floor operations, this cutting-edge printer utilizes an X-Y stage equipped with linear servo motors. By addressing longstanding challenges in strength, speed, and scalability, the HSE 280i redefines the possibilities of additive manufacturing.

Fully Independent

The HSE 280i HT 3D Printer stands as the inaugural 3D printer in the industry to boast true independent dual extruders (IDEX), signifying complete autonomy for each head along both the X and Y-axes.

Speed and Reliability

Harnessing a non-slip, high-torque extrusion system powered by all-linear servo motors, the HSE 280i HT 3D Printer delivers an uncompromising solution. This innovative design ensures both speed and reliability, enabling seamless 3D printing at scale.

Open Ecosystem

In a recent third-party study commissioned, it was revealed that 96% of manufacturers are advocating for open ecosystems to enhance their control. Empowering users with limitless material options, the HSE 280i HT 3D Printer aligns with this demand for greater control.

Specifications

| Print Heads | Two |

| Nozzle | Gen 5 Hozzle™ Heated Nozzle |

| Print Speed | 500 mm/s |

| Filament Diameter | 1.75 mm |

| Nozzle Diameters | 0.4, 0.8 mm |

| Nozzle Temperature | Up to 550ºC |

| Build Volume (Single Head Mode) | 695 x 500 x 600 mm |

| Build Volume (Support Mode) | 595 x 500 x 600 mm |

| Build Volume (Multi-Process Mode) | 595 x 500 x 600 mm |

| Build Volume (Independent Mode) | Future Feature |

| Electrical Requirements | 200–240 VAC, 40A, single/dual phase |

| Net Weight | 850 kg |

| Printer Dimension | 1590 x 1350 x 2490 mm |

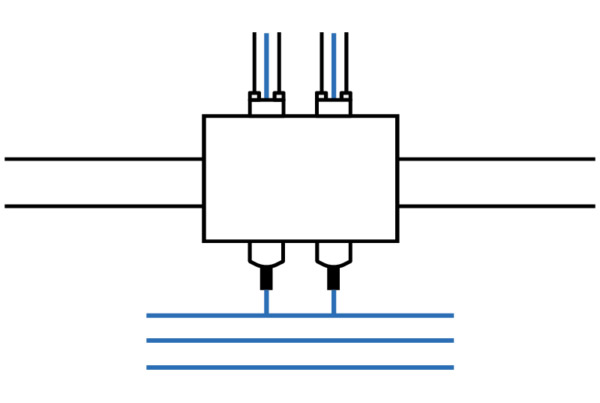

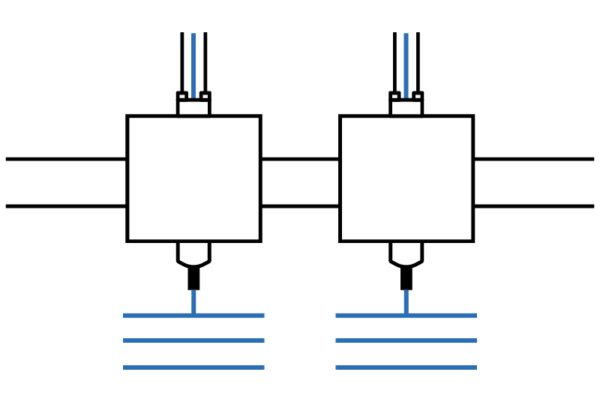

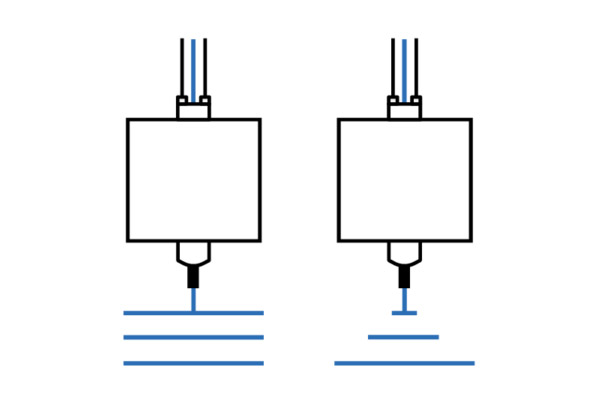

What is True IDEX?

Pioneering innovation, the HSE 280i 3D Printing Platform stands out as the initial industrial 3D printer to provide authentic Independent Dual Extruders (IDEX). Distinguishing itself from other IDEX machines in the market, which position print heads on the same X-axis gantry, the HSE 280i ensures true independence by allowing unrestricted movement on both the X and Y axes. This sets it apart from “semi-IDEX” machines, which are constrained to synchronous Y-axis print modes.

Conventional Dual Extruder

- One head, two nozzles

- Prints primary filament and support material

- Second nozzle may leave filament deposits

Conventional Dual Extruder

- One head, two nozzles

- Prints primary filament and support material

- Second nozzle may leave filament deposits

Conventional Dual Extruder

- One head, two nozzles

- Prints primary filament and support material

- Second nozzle may leave filament deposits

Five Print Modes

With five distinct print modes, the HSE 280i 3D Printer provides a versatile printing experience. The genuine independence of the print heads along both the X and Y-axes offers users the flexibility to efficiently produce parts at scale.

Single Head Mode

Achieve unparalleled printing speed with Single Head Mode, utilizing a single head to print at a rate five to 15 times faster than competitors. Manufacturers can now print at the speed required for staying relevant in the industry.

Copy Mode

Double your productivity with Copy Mode. This innovative feature allows for the simultaneous printing of two identical parts, making it an ideal choice for additive manufacturing at scale.

Multi-Process Mode

Unlock new possibilities with Multi-Process Mode, enabling the printing of two materials or nozzle sizes. This capability is perfect for creating parts with a combination of flexible and rigid features.

Support Mode

Introducing Support Mode, a game-changer for printing complex geometries. This mode facilitates the printing of support structures for parts in progress, utilizing soluble or breakaway materials for optimal results.

Frequently Asked Questions

- Single Head Mode: Prints individual parts at a relevant speed.

- Support Mode: Generates support structures for parts in progress.

- Multi-Process Mode: Prints using two different materials or filament diameters.

- Copy Mode: Simultaneously prints two identical parts.

Note: Independent Mode is a planned future feature.

|

Print mode |

Build volume |

|

Single Head |

695mm x 500mm x 600mm |

|

Multi-Material |

595mm x 500mm x 600mm |

|

Copy Mode |

595mm x 500mm x 600mm |

|

Support Mode |

(395mm x 500mm x 600mm) x2 |

|

Independent Mode |

Coming Winter 2021 |