Resin 3D Printers

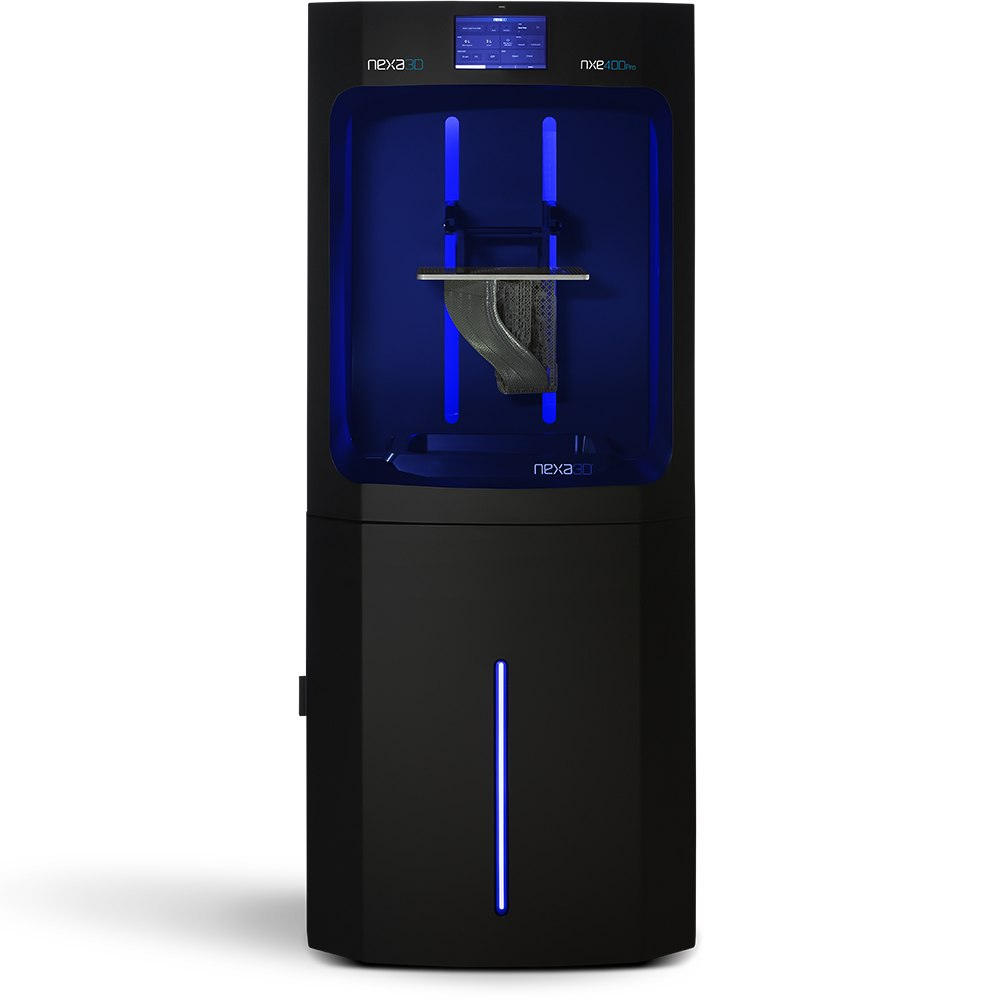

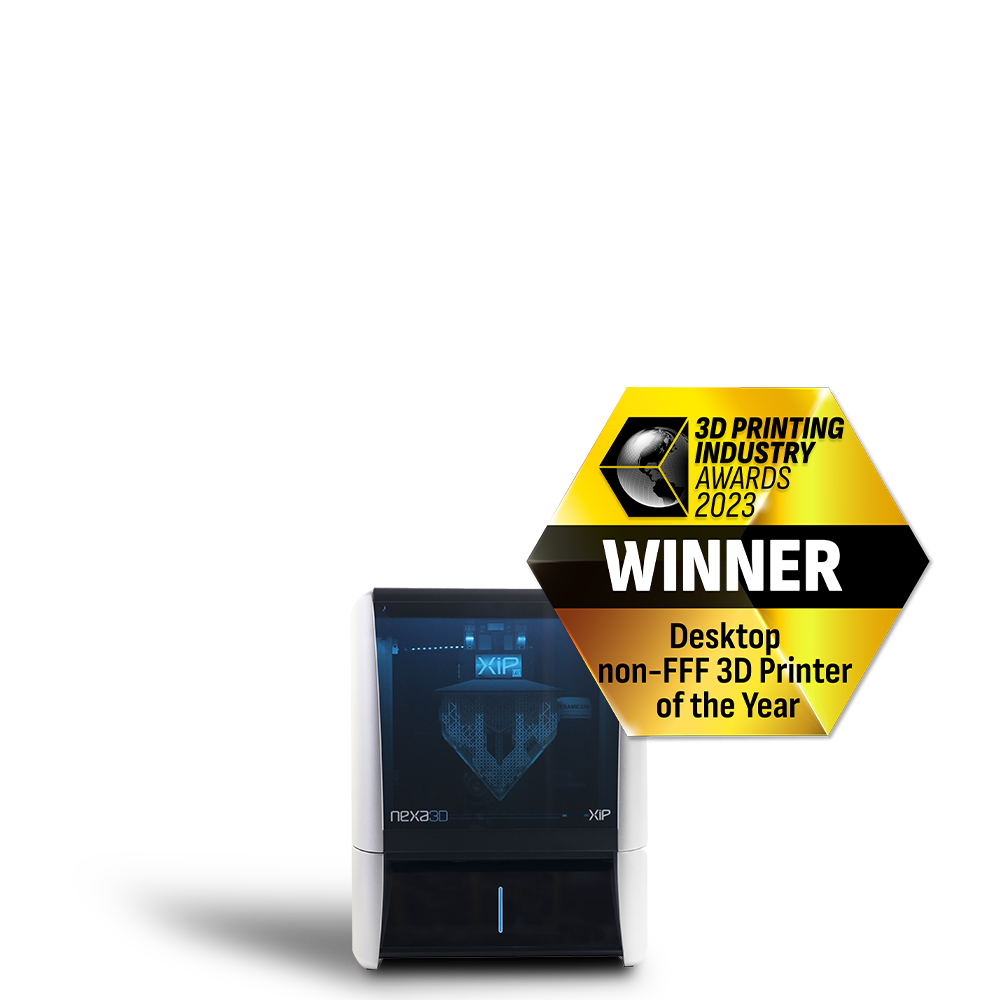

Resin 3D Printers Powered by Lubricant Sublayer Photo-curing® (LSPc)

Resin 3D printers have reached a new peak in additive manufacturing, boasting cutting-edge features such as Lubricant Sublayer Photo-curing® technology and the Self-Lubricating Everlast 2 Membrane. With a stunning 7K resolution, edge-to-edge uniformity, and advanced thermal management, these printers redefine precision, speed, and reliability for engineers at the forefront of innovation.

Talk to a 3D printing specialist to learn more

Industrial Resin 3D Printing powered by Lubricant Sublayer Photo-curing® (LSPc)

Self-Lubricating Everlast 2 Membrane Our fastest, clearest and longest lasting membrane

7K resolution with sub-pixel antialiasing for fine features and smooth surfaces

High power, collimated, 405nm LED light for edge-to-edge uniformity and accuracy across the build

Advanced thermal management for maximum curing reliability in as little as a second per layer

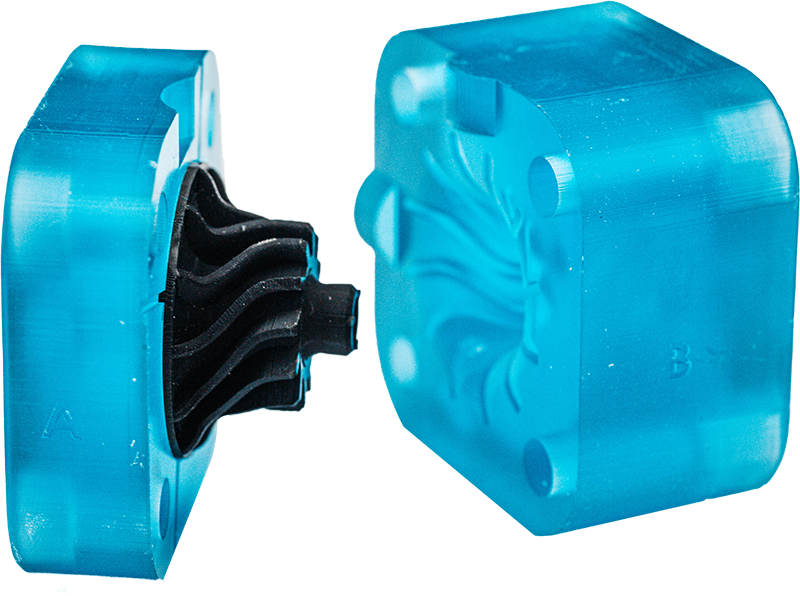

Digital Tooling

Combining design freedom of resin 3D printing with mechanical performance of injection molding plastics

The patented Freeform Injection Molding (FIM) process utilizes rapid Nexa3D printers and xMOLD resin to create injection molding tools compatible with various off-the-shelf materials, including high-performance options. This enables rapid design iteration and validation with production-grade materials in hours rather than weeks, a significant advantage in product development.

“With the extremely tight deadline and challenging manufacturing process we could not have met our manufacturing dates with any other process as the iterations involved very challenging painting/lighting effects. The XiP enabled us to move revisions into physical form faster than printing in other slower technologies.”

– Jason Lopes, Dir. of Additive Manufacturing at Gentle Giant Studios

NEW!

Download 2024 Resin Material Guide

Latest and greatest resin materials in 2024 featuring xMOLD, xESD, FR, xDENT, and more.