Congrats – you made a great decision to invest in ultrafast 3D printing! But wait, it’s about to get even better…

The Nexa3D LSPc 3D printing solution you have decided to buy is already leading in speed, productivity and total cost of ownership. And now we further increase the value of your investment by offering you the most comprehensive factory upgrade ever delivered. The xMOLD resin, used in Freeform Injection Molding, fundamentally transforms the concept of “open materials”. xMOLD 3D printed tooling resin is compatible with thousands of already qualified injection molding polymers, metals, ceramics and rubbers. This means you can print digital tools using the xMOLD resin and instantly produce prototypes using final injection molding materials. Yes, prototyping using the same process and materials used in final production is now possible!

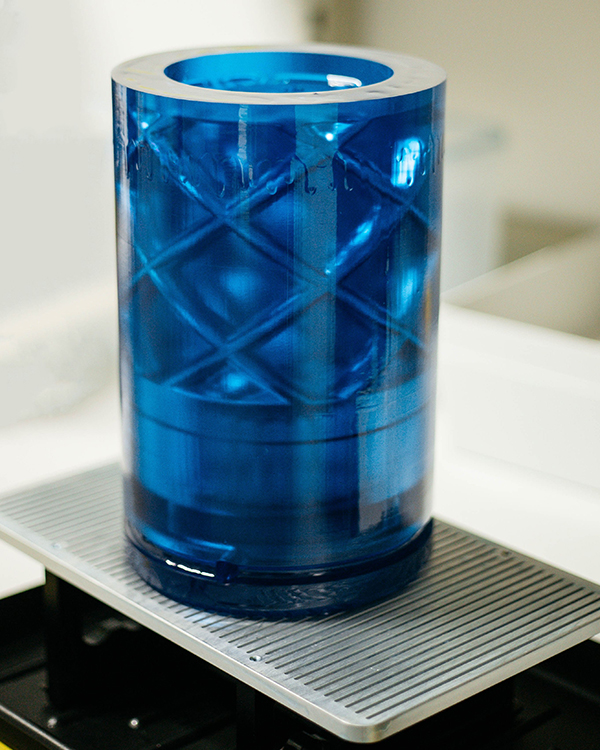

There are two ways to use 3D printed tools printed with XMOLD resin. You can create rapidly create mold halves that are compatible with thousands of off-the-shelf injection molding materials, including reinforced high-performance feedstocks. The ability to design, iterate, and validate using final grade production materials in hours versus weeks is invaluable in any product development process. The tools printed in XMOLD resin are also fully soluble, enabling true design freedom and eliminating the need for time consuming design and gating considerations typically associated with conventional tooling process. You can quickly design and print tools for highly complex parts, inject with injection molding feedstock, and then simply dissolve away the tool to reveal the complex shape underneath.

Why would you want to try xMOLD resin?

The simple answer: Because it allows you to do more on the same investment. The way they are processed matters. And we are deeply committed to increasing the range and quality of parts that can be additively manufactured. With LSPc, we democratized resin 3D printing, enabling you to use whatever photopolymer that meets your requirements. With xMOLD, we democratize injection mold tooling, to effectively tear down the wall between additive manufacturing and injection molding. And in doing so, we rewrite the playbook of product development. Now xMOLD and LSPc allows you to migrate seamlessly from ultrafast 3D-printed prototypes to injection molded products, without hit-or-miss investments in high-cost metal tooling. To bypass service provider queues and print the tools you need when you need them. To either fill them in-house or get someone else to fill them for you. Prototyping of injection-molded parts has never been this fast – or this easy.

Where do I start?

Getting started with injection molding may seem a bit daunting at first – especially if you have little or no experience with the process. This is why we have already set up the infrastructure to help you succeed from the get-go – and to build the knowledge you need to take over. Of course, if you are already a seasoned mold designer – perhaps with presses already installed – you should simply get in touch with your authorized reseller to start reducing cost and lead-times. But for those of you who are new to injection molding, we are happy to lend a hand:

- Mold design – is something you can get as a service. Also if you want to print – and even fill – the molds yourself. At Nexa3D, we have carried out more than 600 mold design projects to date, and we are here to help you get started. Based on the part(s) you want to (have) produce(d), we can help you design and validate – and guide you on the steps you need to develop your in-house skills

- Printing of molds – including cleaning and curing – is something you can already do on your LSPc. You’ll get the parameter sets you need – as well as your first supplies of xMOLD – from your authorized reseller, along with design and process guidelines.

- Injection molding – is available as a service, if you prefer to keep investments low. And if you want to further cut your costs and times-to-market, we will be happy to advise you on how to get started with injection molding on your own floor

- Demolding – involves alkaline solvents and takes place in a dedicated workstation. Depending on your preferences and your set-up, it may either be something you do on your own floor, or it may happen on the floor of the service provider doing the molding.

How Does it Work

What do I need?

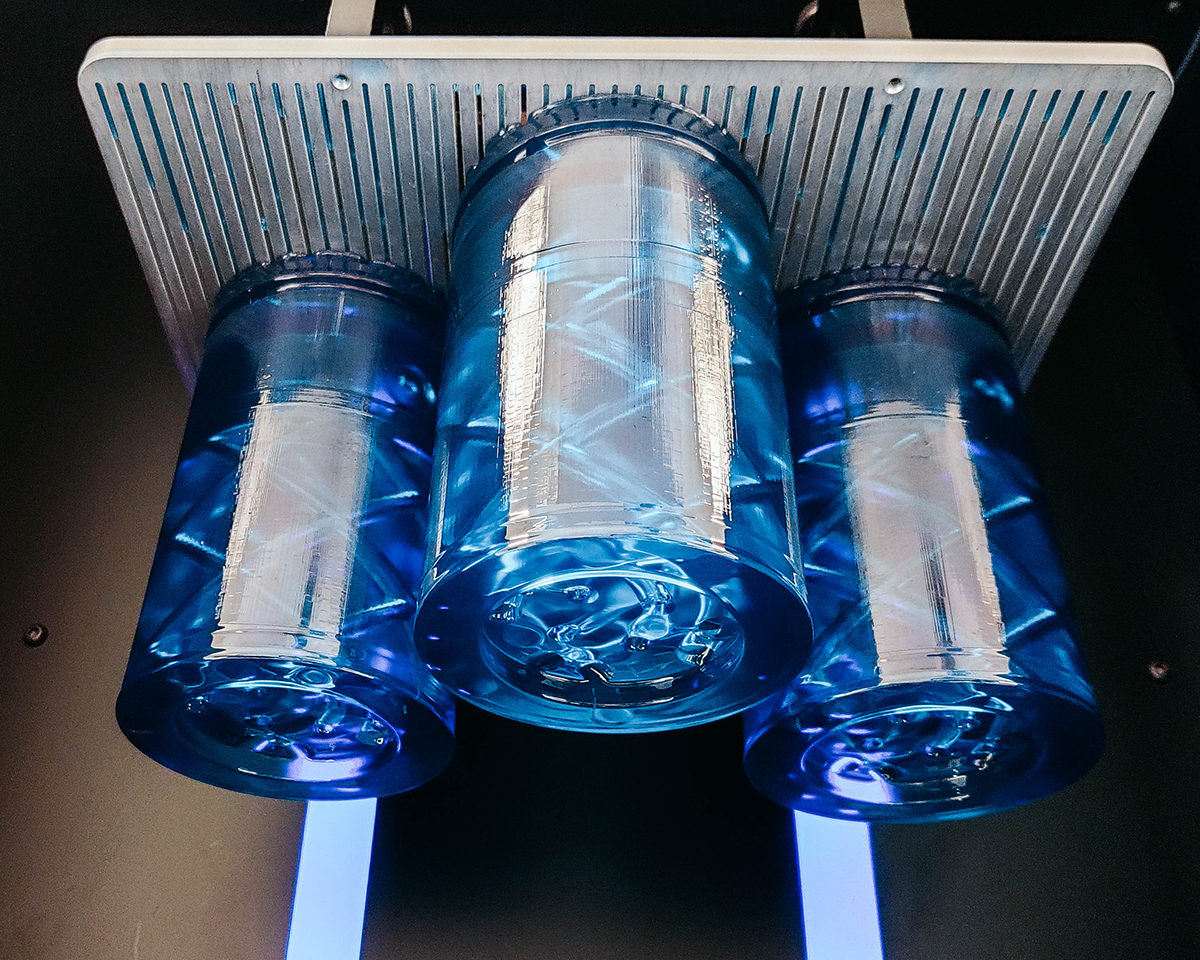

To get from ultrafast LSPc 3D printing to ultrafast injection molding, you’ll need an injection press and a demolding station in addition to your xMOLD resin. And you’ll want this hardware as close as possible to your Nexa3D printer cell as logistics start mattering when speed is of the essence. Below are listed the different demolding solutions we offer, and we will be happy to offer guidance on the selection of injection presses for your specific needs.

- DD1 – when ventilation is critical

- XWASH-FIM Desktop Demolding System – for high-speed applications on your desktop

- XWASH-FIM Industrial Demolding System – for industrial use on the factory floor

Ready to get started? We’re here to help. Contact our FIM Specialists today.