Perrigo Increases Production Speed with Rapid 3D Printing Solutions from Nexa3D

For Perrigo, whose production lines generate around $20,000 an hour, avoiding downtime is a business-critical objective.

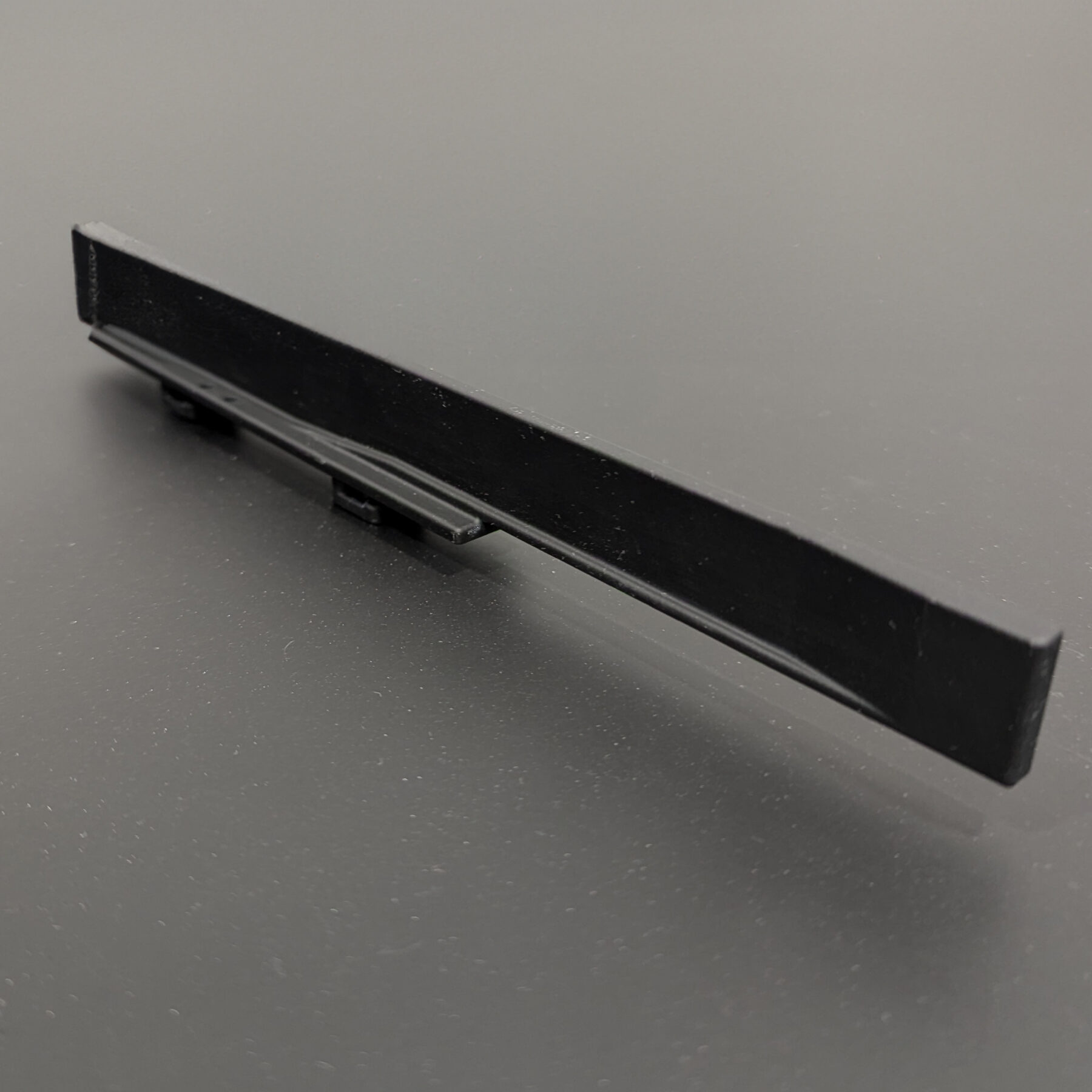

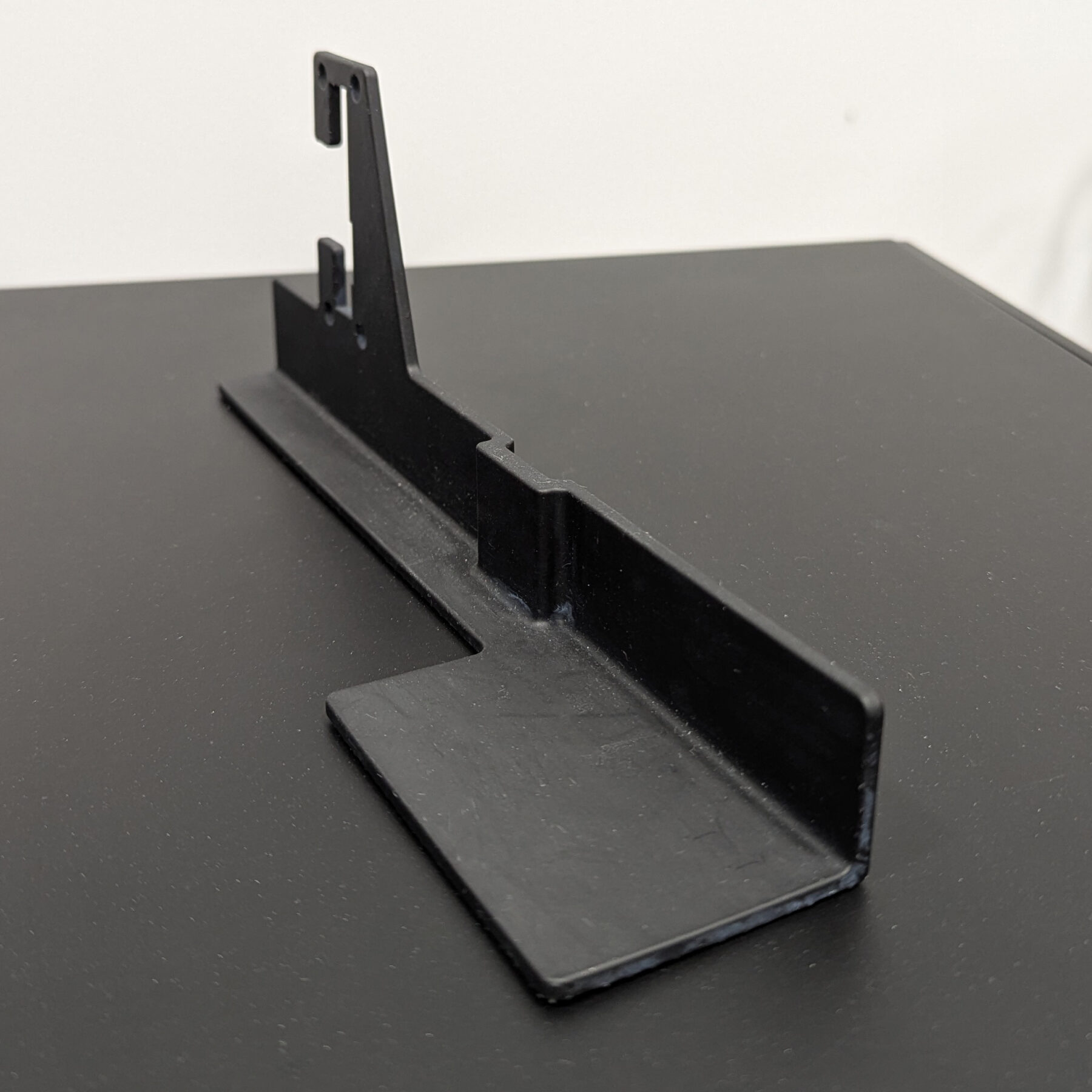

Perrigo is a leading over-the-counter (OTC) pharmaceutical company selling products that are familiar to most grocery stores across the US and globally. The company recently turned to 3D resin printing to manufacture previously outsourced original equipment manufacturer (OEM) items, such as cartoners and caps, to ensure they were always in stock and available for production.

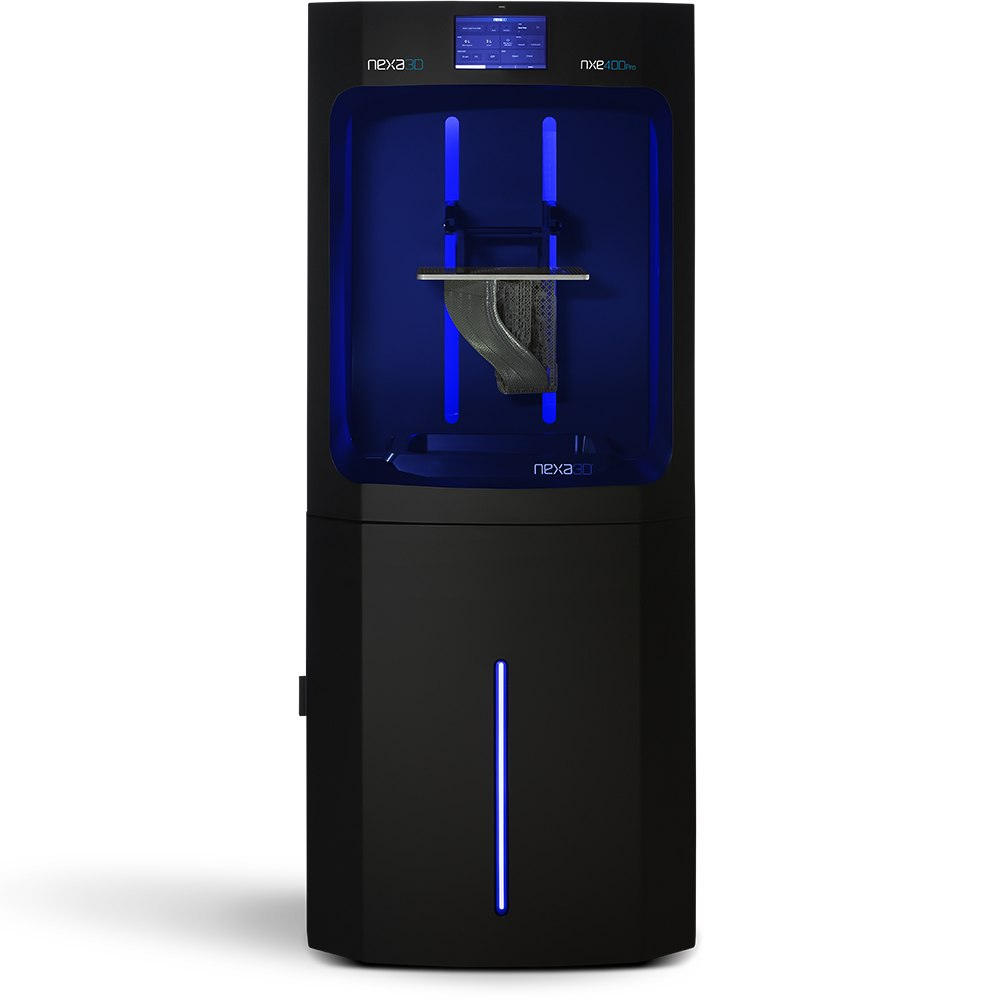

The speed of the Nexa3D NXE 400Pro, which can produce full builds in as little as two hours, has allowed Perrigo to keep stock levels high and production lines running without interruption. This saves the company approximately $8000 monthly in replacement parts alone.

Challenge

Pharmaceutical retail products require a range of OEM parts, particularly for packaging. Kevin Moore, 3D printing engineer at Perrigo, explains, “Parts are designed specifically for each product, and they are generally quite expensive to source from the OEM. We also have the issue of being dependent on them for continuous supply. If the OEM has an issue with their manufacturing or logistics processes and we don’t have the right parts in stock, our production lines must stop while we wait for the product. At the volumes we work with, this downtime costs us on average $20,000 per hour in lost revenue.”

He continues, “With some lead times for OEM products taking as long as two months, we wanted much more control over our supply chain to ensure continuous production. At that time, we were also working with Burton Precision, using their scanners to produce 3D models for printing, and they recommended we speak to Nexa3D.”

“We adopted Nexa3D’s resin printing technology, and by leveraging the speed and versatility of their printers, we began manufacturing replacement parts in-house. This reduced lead times from two months to two hours!”

– Kevin Moore, 3D Printing Engineer, Perrigo

Customer

Perrigo

Industry

Pharmaceuticals

Products

- NXE 400Pro Industrial 3D Printer

- xABS3843 Resin

Application

Manufacture OEM parts for OTC pharmaceutical packaging production lines, including cartoners and caps.

Advantages

- Products with two-month lead time can be produced in two hours

- Enables continuous and uninterrupted production lines

- Save potential financial loss of $20,000 per hour due to downtime

Solution

Perrigo recognized the potential of 3D printing to transform its maintenance processes. “We adopted Nexa3D’s resin printing technology, and by leveraging the speed and versatility of their printers, we began manufacturing replacement parts in-house. This reduced lead times from two months to two hours!” says Kevin.

After installing Nexa3D’s NXE 400Pro printer, Perrigo integrated the technology into its production workflow. Derek adds, “The best thing about the printer is the speed with which it manufactures the parts we need so they are always available. This ensures continuous production and uninterrupted operations, delivering huge cost savings.”

Thanks to Nexa3D’s resin printing technology, Perrigo has achieved some very positive results in terms of cost savings, production efficiency, and maintenance agility. “By producing parts in-house we have significantly reduced procurement costs and operational downtime, and this delivers substantial financial benefits for the company,” concludes Kevin.

Download 2024 Resin Material Guide

Latest and greatest resin materials in 2024 featuring xABS3843, xMOLD, xESD, FR, xDENT, and more.