Toyota Accelerates Break-Through Development with Freeform Injection Molding

Toyota, Nexa3D, J. Krebs & Co prototype novel electrochemical device

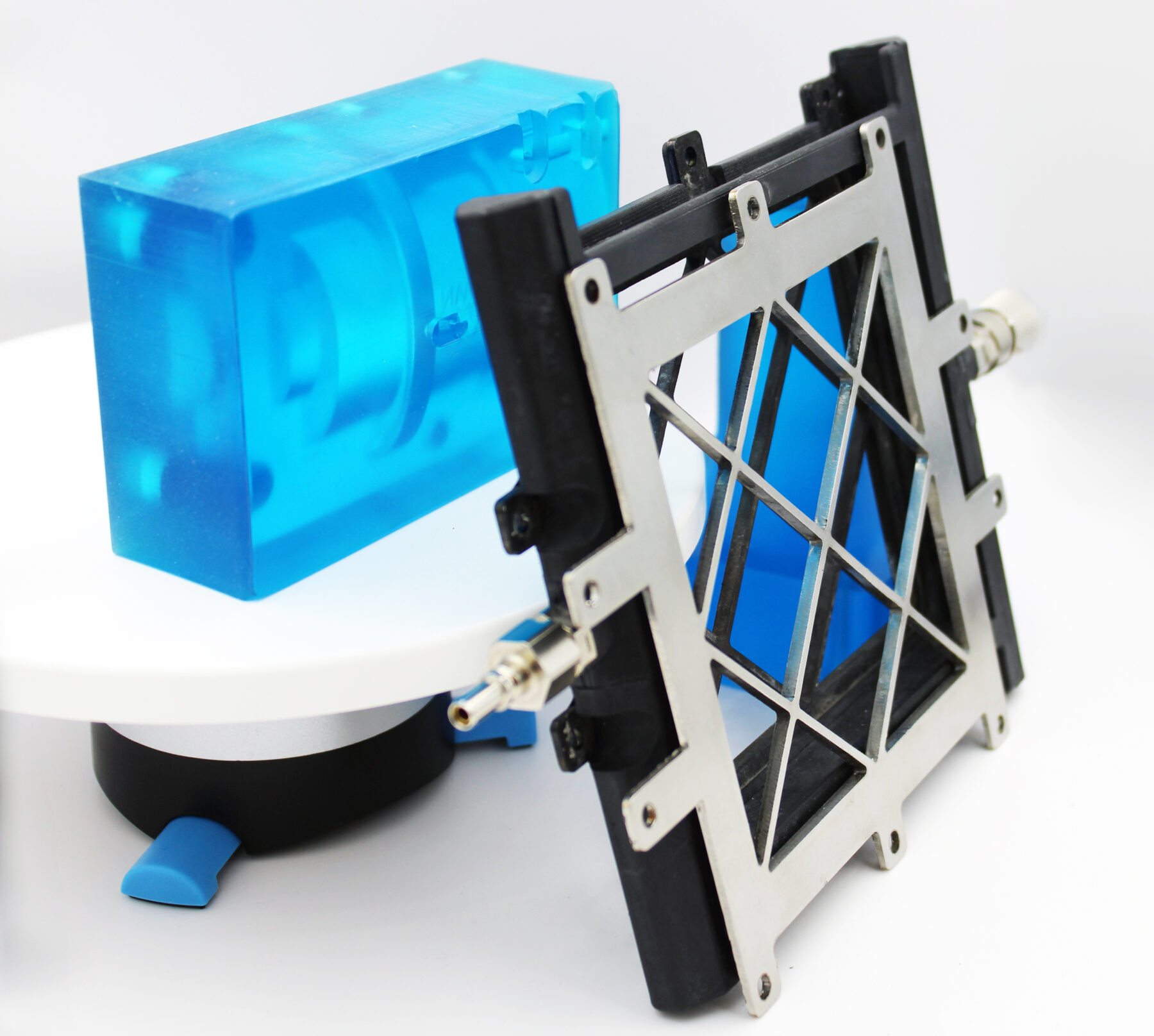

In the spring of 2024, Toyota teamed up with Nexa3D and injection molding pioneer J. Krebs & Co. to work towards making a low volume prototype of a housing for a novel electrochemical device. The promise of Freeform Injection Molding allowed Toyota the capability to change designs without fixating the mold design.

The tools used to power this acceleration: 3D printed soluble injection molds.

Challenge

Rapidly Prototype Design for Housing with Integrated Metal Inserts

The Toyota project was based on break-through innovations in the field of material science, and the requirements faced by the development team were defined in advance: “Provide a three-part prototype assembly, incorporating metal grids in a specific metal that are housed in water-tight, weather-proof enclosures – and manufacture the assembly using processes that are highly scalable”.

Following a period of research and experimentation, the Toyota team heading the development came across Nexa3D’s Freeform Injection Molding. This technology, which enables injection molders to prototype injection-molded parts with the speed and design freedom from additive manufacturing, has been used by companies in a wide range of industries to accelerate product development and support rapid product launches. And it is available as a manufacturing service – which was of key importance to the Toyota team.

“Through FIM, we were able to prototype with injection molding at low volumes. This unique benefit allowed us to remain flexible at design stage while prototype with injection molding technology which would be more representative for higher volumes in the future”.

Jason Fernandes, Senior Engineer, Toyota Motor Europe

Solution

Overmolding with 3D Printed Soluble Injection Molds

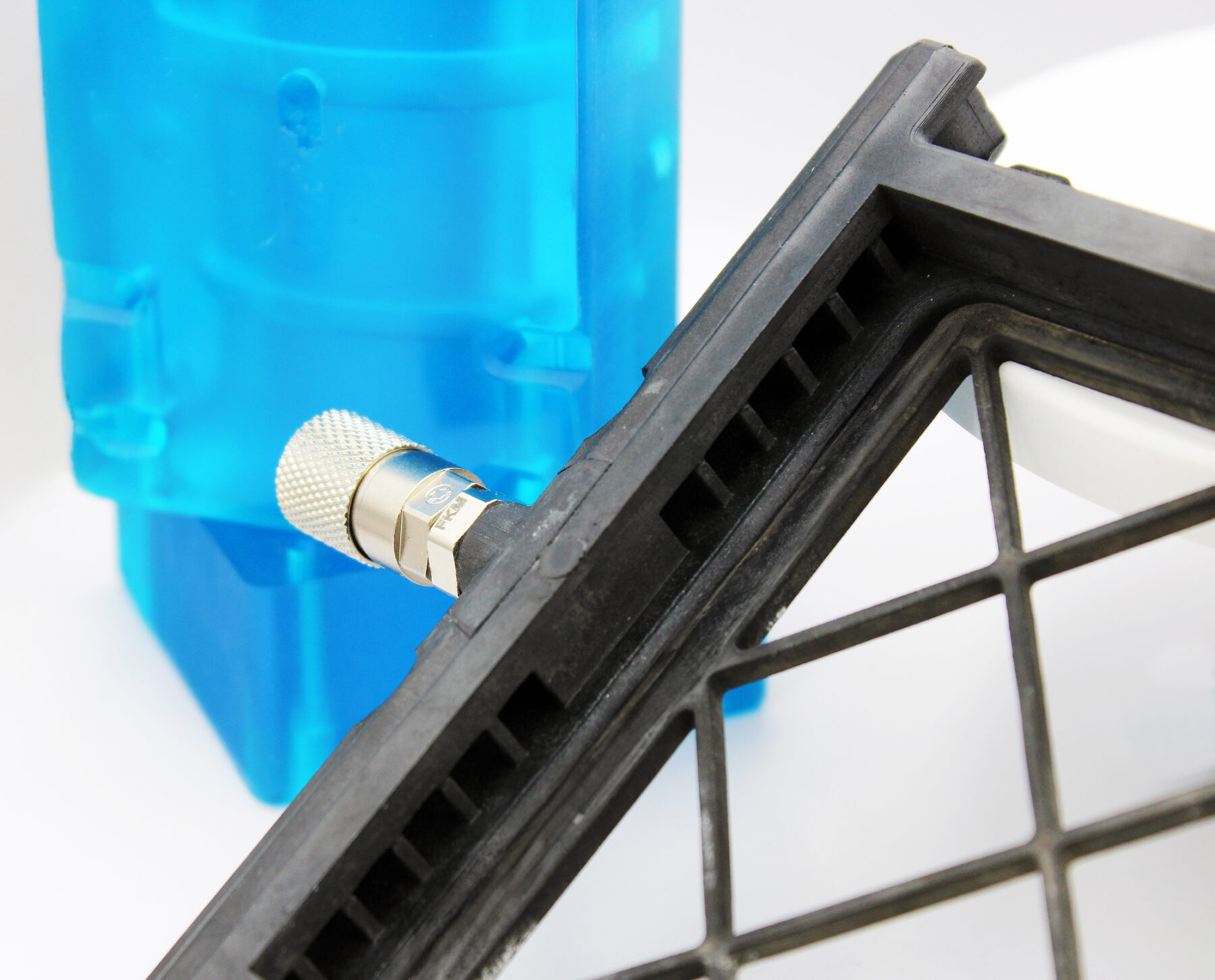

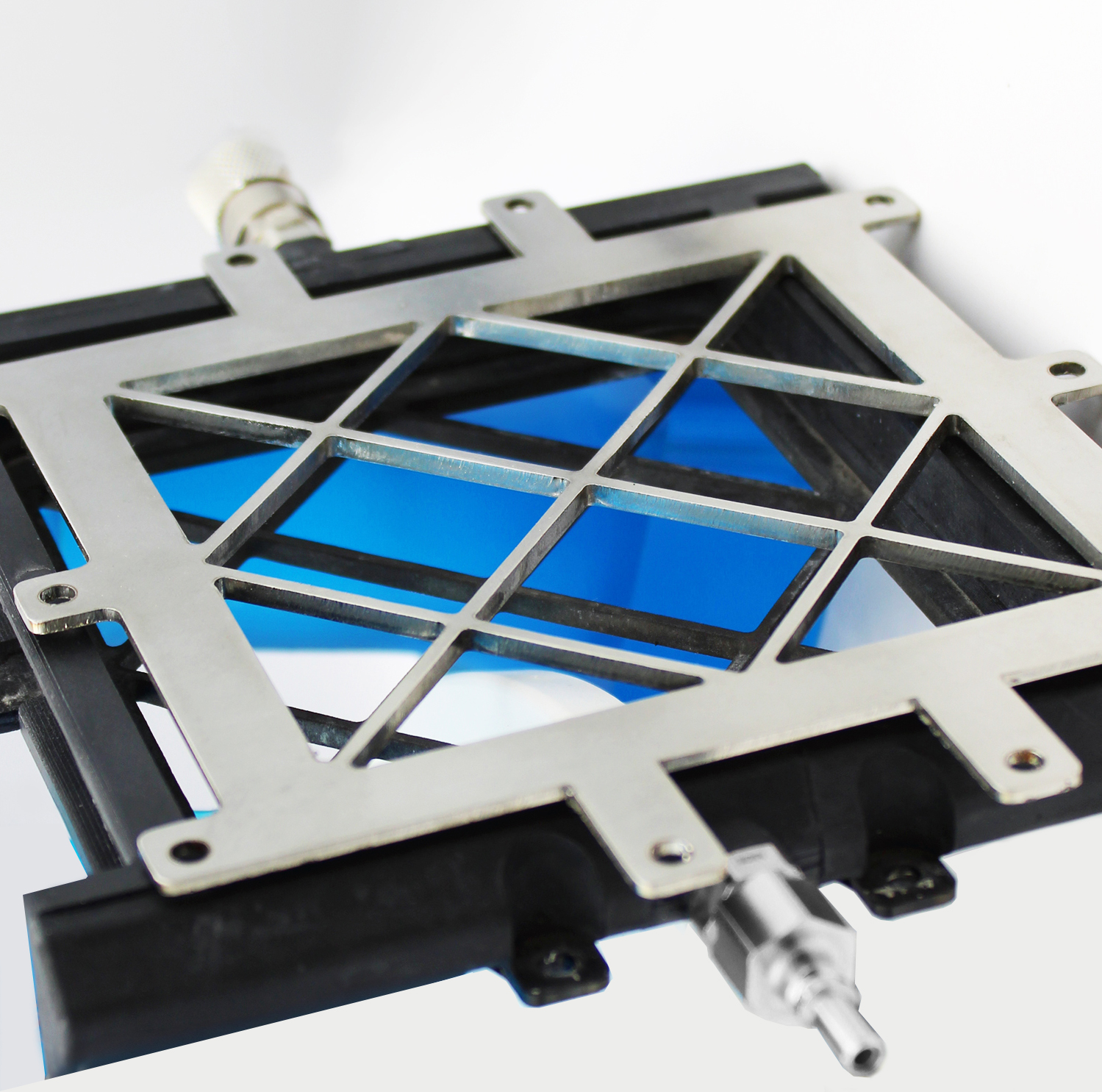

The housing design comprised of a complex sandwich of a plastic housing to assure electrical isolation and metal inserts that had the role of providing electrical contact and end to end inserts to allow for easy connections for modular connections. Water-tightness was a key requirement for which the design was adapted in multiple rounds of parts creation, and which remains a key focus going forward.

Overmolding is a well-known approach used in the injection molding industry where metal and polymer elements need to be combined. Key benefits of this approach include tight integration of elements, high mechanical stability and tight fits promoting high levels of native water tightness.

Overmolding of the connectors was achieved with relative ease and remains a key feature of this technique that allows us to place custom metal inserts within the mold.

For the Toyota project, a metal grid and two metal connectors needed to be integrated into a housing in a high-strength, non-conductive polymer housing that needed to combine excellent weather stability and chemical inertness. After consulting with experts from Nexa3D and J. Krebs & Co., the FIM manufacturing partner involved in the project, a PPS (Polyphenylene sulphide) with 45% glass-fiber reinforcement was chosen as the housing material. Since a key project objective was to maximize environmental compatibility, a recycled grade from German company Mocom was chosen for the prototyping and verification.

Once the manufacturing approach had been determined, the design team from J. Krebs & Co worked out the first mold design. Considering the size and number of parts to be molded, the XiP Pro was identified as the most appropriate Nexa3D printer for the job. To realize the mold design itself, which included a number of intricate part features and several undercuts, xMOLD was chosen as the tooling resin. This resin has already demonstrated that it is capable of handling the high pressures (in this case up to 110 bar) and temperatures (up to 340 degrees) used for the molding of PPS and other high-performance polymers, and fully molded prototype parts were available less than two weeks after kick-off.

Benefits

The accelerated prototyping of a complex polymer part assembly incorporating multiple over-molded metal elements is a daunting task by any standards. Mold design and sourcing of prototype metal elements had to be done in parallel, which made tolerance chain management extra challenging. When using metal molds, a very tight fit between metal parts and mold interfaces has to be guaranteed, and this fit is difficult to achieve in an immature prototype supply chain operating on tight time schedules. However, the increased ductility of xMOLDs, compared with the rigidity of conventional metal molds, enabled the design team to initially design for maximum mold tightness which enabled the successful molding of proof-of-concept parts already in the first iteration. At the same time, the mold design could be easily and quickly updated to capture learnings from the first iteration, which enabled the project to move from CAD concept to physical verification with a very low level of risk and uncertainty.

- No minimum order quantities since the molds could be printed on demand. For the first iteration, two molds were printed and the second shot resulted in a fully molded proof-of-concept part.

- Prototypes in end-use materials since the xMOLD resin possesses the mechanical and thermal stability needed for the molding of PPS and other high-performance materials. In addition, the strong insulation – and resulting low heat loss – offered by the xMOLD material allows semi-crystalline materials like the PPS to achieve high crystallinity levels.

- Simplified mold designs since the xMOLD material is soluble. Part features that would normally require the use of sliders, cores or other mold complications can be easily realized with soluble mold elements in the prototyping stage