Manufacturing

Our Industrial 3D Printer Lets You Make More, So You Can Make More!

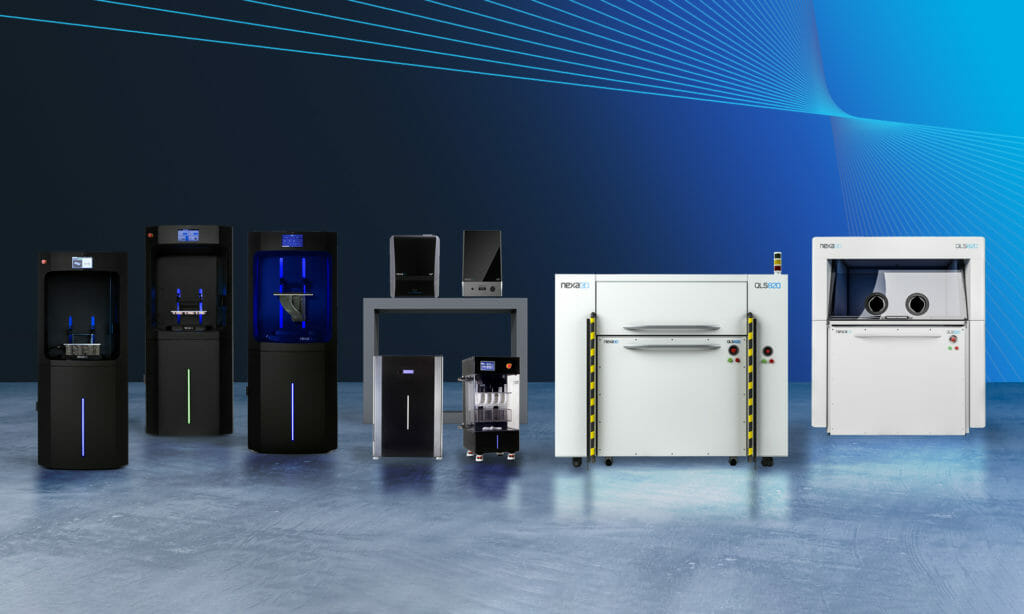

Industrial 3D Printers

At Nexa3D, we’re committed to helping manufacturers enhance their efficiency through our robust and rapid additive manufacturing. Our 3D printing and additive manufacturing technology can give you more control of your supply chain and allow you to digitize your inventory for benefits that include:

- Enabling of on-demand manufacturing

- Streamlining of processes

- Lowering working capital requirements

- Allowing for on-site per demand production of spare parts

- Freeing up working capital

- Reducing environmental waste

…And with Nexa3D technology, it’s all done at an 85% lower total cost of operation!

Nexa3D is committed to digitizing the world’s supply chain sustainably by making the world’s fastest polymer 3D printers affordable for companies of all sizes — including yours! Our unique LSPc technology breaks the speed barrier by actively overcoming the traditional speed-limiting factors of traditional SLA without compromising dimensional accuracy, high-quality surface finish, and structural integrity. The result is 20X more productivity that will allow you:

- Flexible tool-less production

- Improved product performance

- Faster production at scale

- Mass customization

- Design agility

Continuity and Unification

Our industrial 3D printer technology allows for innovative and optimized design configurations that can be produced quickly and assembled in a single operation, reducing set up time to nearly zero! This technology gives your design and production teams tremendous flexibility and reduces the amount of labor needed in the manufacturing process.

Book a Meeting

Our Circular Economy Design Principles Mean a Better Bottom Line and a Better World!

Our 3D printing for production parts leverages circular economy principles in every phase of the design and delivery process by rigorously measuring and improving on what matters:

- Minimizing process waste

- Reducing energy consumption per part

- Working with our customers to reduce their overall carbon footprint

- Making it possible to produce parts on-site and on demand, reducing carbon footprint

- Optimizing parts for lightweighting, parts combination, and reduction of power consumption per part through our Digital

- Twin Software