Breaking Speed and Size Barriers

HAUX-LIFE-SUPPORT demands outstanding technical performance, innovation, quality and reliability because their life-saving equipment can’t fail. They trusted the NXE 400 because of its ability to deliver the quality and tolerances the product demands.

Since its founding in 1980, HAUX-LIFE-SUPPORT The company develops and manufactures state-of-the-art systems and equipment, provides tailor-made solutions for customers, and has more than 1,500 hyperbaric HAUX systems delivered worldwide. Over the past almost 4 decades, HAUX-LIFE-SUPPORT has become the world market leader in the fields of medical, tunneling, and diving technology.

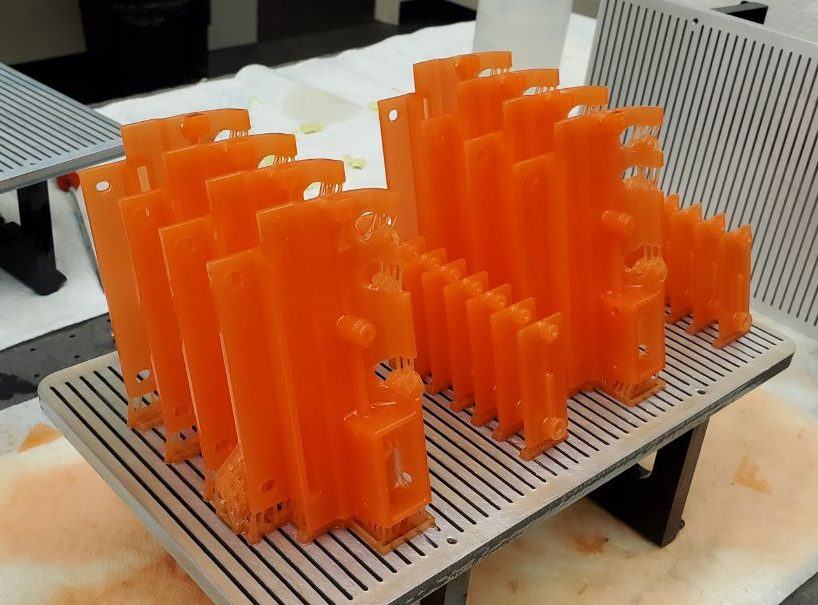

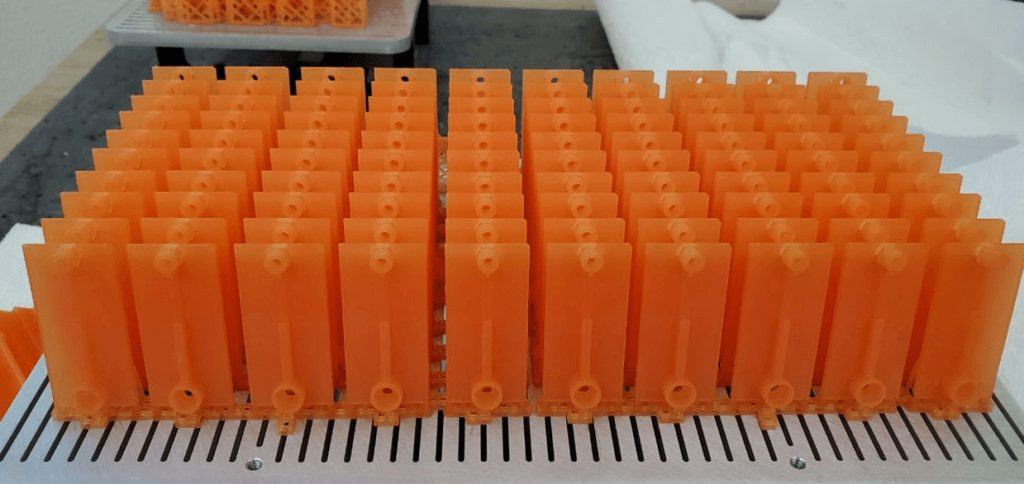

The company needed to produce high and low pressure equipment for medical applications and diving bells for underwater applications. The medical devices are used to treat certain illnesses; diving bells are used to rescue divers, for example, who had an accident under water and cannot rise above sea level).

High-Pressure Production

When another human life is on the line, product quality must be at the highest. HAUX needed complex, dependable parts at the ready to keep production moving.

Precisely What Was Needed

The NXE 400 delivered essential reliability and precision, at unmatched speeds, to meet HAUX’s stringent production standards and timelines.

Speed and Reliability

The NXE 400 provided fast turn times for proptypes and high-quality end-use parts that allow HAUX to keep production moving without sacrificing quality.

A Local Solution for Complex Machining

The company had a set of standard parts for most product manufacturing, but some required complex custom parts made in Germany, specifically designed for the application. HAUX’s products contained up to 500 parts to finish the project. Missing any of the imported parts could hold up deadlines.

Many of these parts were very complex and needed to be 3D printed. Only parts printed with the Nexa3D NXE 400 gave them the speed, precision and reliability to finish the projects on time.

Prototypes Within Minutes

Nexa3D’s unique LSPc technology breaks the speed barrier by actively overcoming the traditional speed limiting factors of traditional SLA without compromising accuracy and resolution. With the parts printed on the Nexa3D NXE 400, HAUX produced prototypes within minutes. They were also able to produce the end use parts in the 100 to 500 range within less than a day.

“With Nexa3D’s innovative NXE 400, we were able to produce functional end use parts at a very high speed with great precision and reliability.”

Mr. Paul Ziegenhagel

The Speed to Meet Important Deadlines

Boasting 6 times the speed and 2.5 times the volume of all other comparable 3D printers on the market, the Nexa3D NXE 400 gave HAUX the ability to create prototypes fast. In addition, the parts produced were functional end-use parts, making it possible to meet demanding shipping deadlines.

Download PDF