- Formnext Reflections: Catalyzing Innovation, Building the Future of AM Solutions - November 19, 2024

- Best Filament Materials for 3D Printing Flight-Ready Aerospace Parts - August 1, 2024

- 9+ Filament Materials for 3D Printed Fixtures and Jigs - July 21, 2024

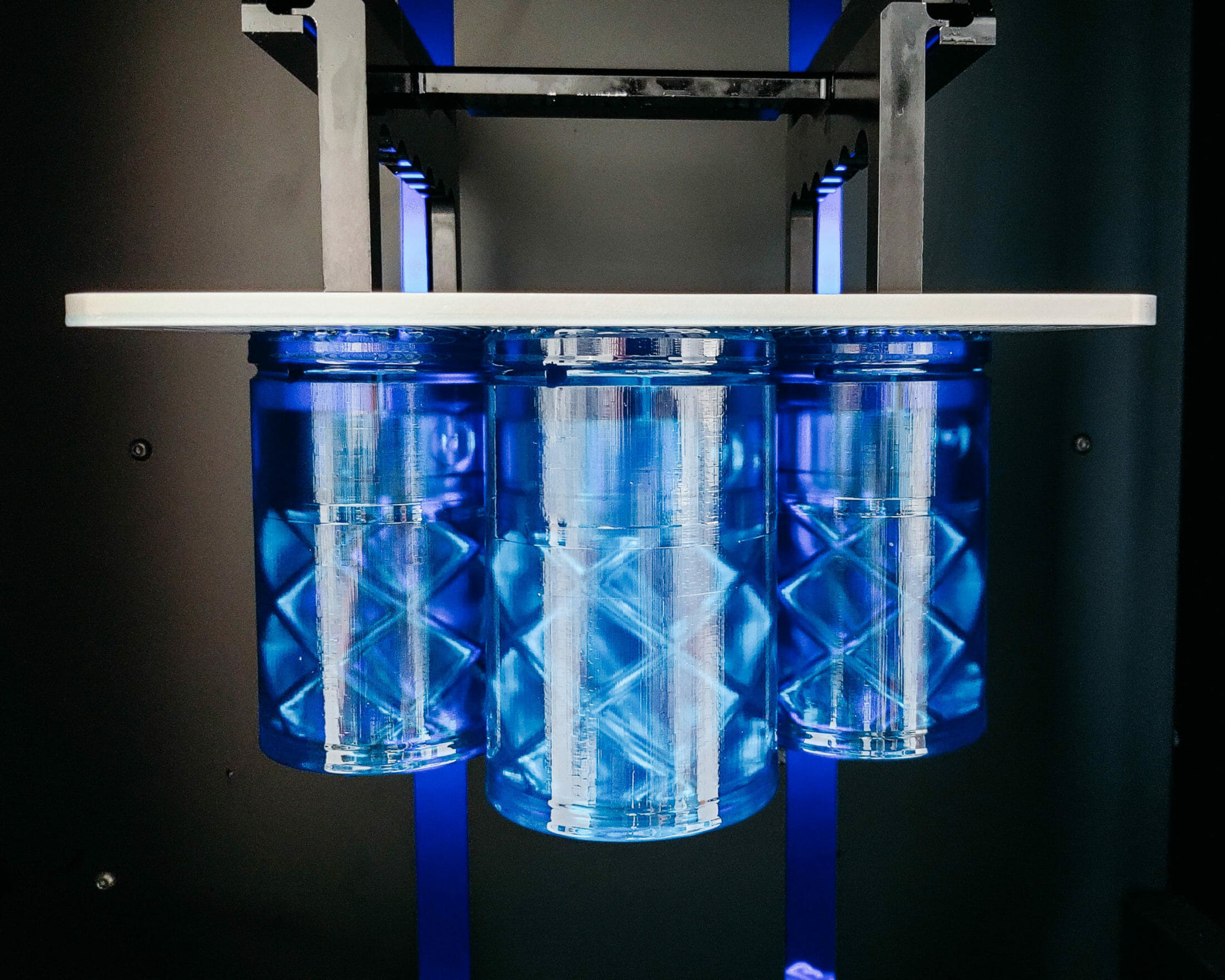

Our product offering and material capabilities continue to expand with today’s acquisition of Addifab. Addifab is the originator of Freeform Injection Molding, a patented digital tooling resin and dissolvable tool process that couples the design freedom of 3D printing with the mechanical performance of injection molding.

Located in Copenhagen, Denmark, Addifab developed, patented, and successfully brought to market a proprietary end-to-end digital tooling solution that includes CAD-to-Tool software generator, dissolvable tooling resins, 3D printing and production injection molding process. By combining the best of freeform additive manufacturing with the industrial strength of injection molding, Addifab unlocks tremendous potential for contract manufacturers, regional molders, service providers and low-volume manufacturers looking to take full advantage of the design while using tried and proven injection molding plastic materials for same day and next day part production.

The acquisition follows a successful year of joint go-to-market collaboration between the two companies in both North America and EMEA. The joint sales and marketing efforts resulted in converting dozens of customers from traditional tooling to digital tooling due to significant time and cost savings associated with this innovative approach. The transformative end-to-end solution combines the best of Nexa3D’s ultrafast 3D printers with Addifab’s high-impact, high-temperature soluble resins to print complex tools that are compatible with any injection molding feedstock, thereby delivering complex tooling at a fraction of the cost and time of other 3D printers or conventional tooling processes.

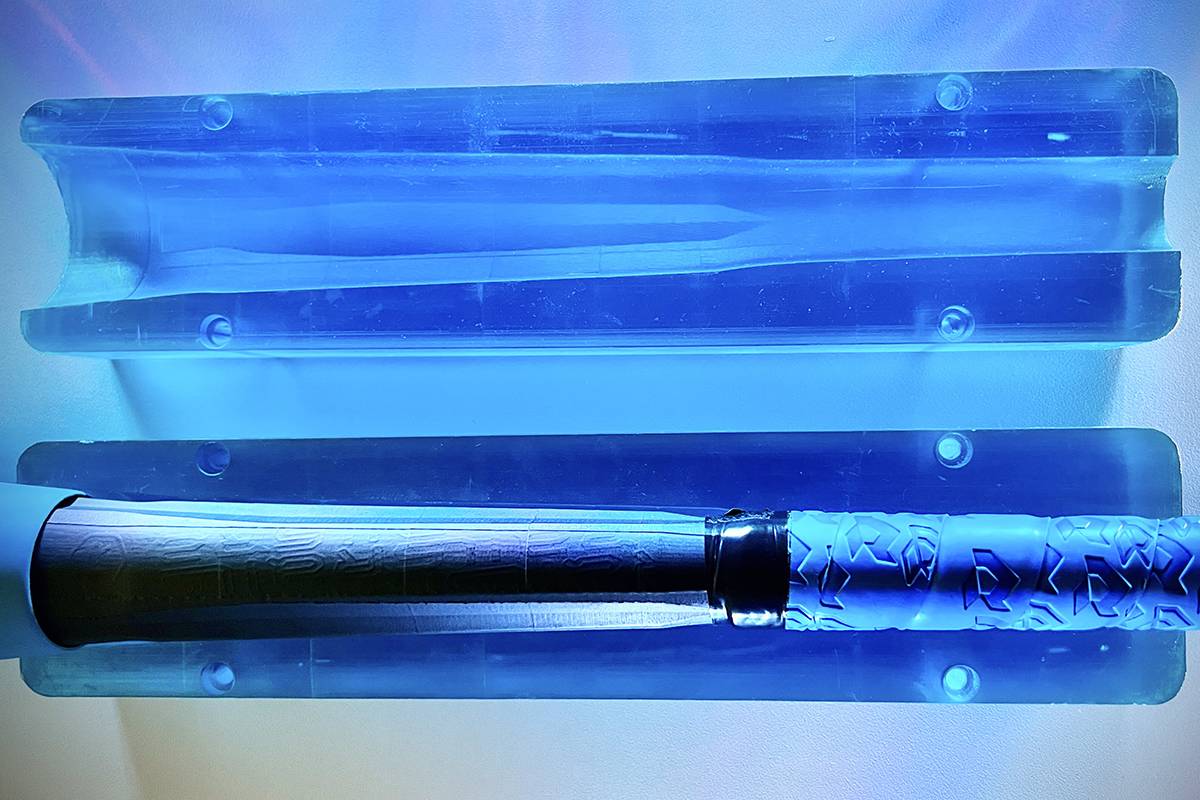

Most notably, the combined solution was used by Wilson Sporting Goods to accelerate the development of youth baseball bats. Wilson’s R&D team was able to produce and test multiple design iterations at once by combining a 3D printed tool with final manufacturing materials during the prototyping phase.

“Because we can iterate so much quicker, our R&D team can afford to be wrong. This helps us greatly improve our time-to-market, allowing us to be quick and nimble with our design decision-making process.”

– Glen Mason, Advanced Innovation at DeMarini Sports

Addifab’s proprietary tooling resin will be rebranded as xMOLD and offered to all Nexa3D customers for use with all of our resin-based 3D printers. The xMOLD resin can be used in a traditional split mold application for repeated use, or in a unique dissolvable application taking full advantage of design freedom of 3D printing. The xMOLD resin is compatible with over 300 off the shelf injection molding materials, including reinforced high-performance feedstocks. And because the xMOLD tools are soluble, no special design considerations need to be given to slides or gates, giving manufacturers the ultimate flexibility to test and iterate more frequently. Most importantly, you don’t have to be a toolmaker to quickly design an injection molding tool using the Addifab tool maker software or another popular CAD tool.

Why did we acquire Addifab?

- Combining design freedom and industry leading print speed with ubiquity of injection molding significantly broadens true production capabilities for our customers

- Dissolvable tooling creates same day production opportunities for highly complex, otherwise unmoldable geometries

- Specialized tooling resin is compatible with hundreds of injection molding feedstock, enabling prototyping and production using final grade materials

- New Customer Experience Center in Copenhagen, Denmark

“We are very excited to welcome the entire Addifab team to the growing Nexa3D family of people, products and partners democratizing access to dissolvable tooling for same day complex molded parts with hundreds of industrial plastics.”

– Avi Reichental, Co-founder, Chairman and CEO of Nexa3D

As part of its growing commitment to EMEA, and in service of our growing reseller partner network, we plan to immediately leverage Addifab’s Copenhagen facility as our new Customer Experience Center, inclusive of a product showroom, service and support hub, and a main European fulfillment center. This move further emphasizes our commitment to geographic expansion, customer success, and broadened access to our ultrafast 3D printing technology and digital tooling solutions.