MaxResolution3D Relies on Nexa3D to Build its Manufacturing-as-a-Service Business

The NXE 400 platform proved to be the system of choice for establishing scalable services at MaxResolution3D with help from the team at ProductionToGo.

![]()

Berlin-Based Startup Seeks Serial Production Platform

Birthed in 2021 after a pre-seed funding raise from private investments, Berlin-based startup MaxResolution3D seeks to take on serial production using Nexa3D’s additive manufacturing platform to help close the gap between injection molding, machining, and other traditional manufacturing technologies. Co-Founders Max Männel and Dario Dill have been friends since high school and first got in touch on a work base by scaling Männel’s former e-Commerce startup, Stoeberstube030. In February 2021, they decided to start their second venture through MaxResolution3D.

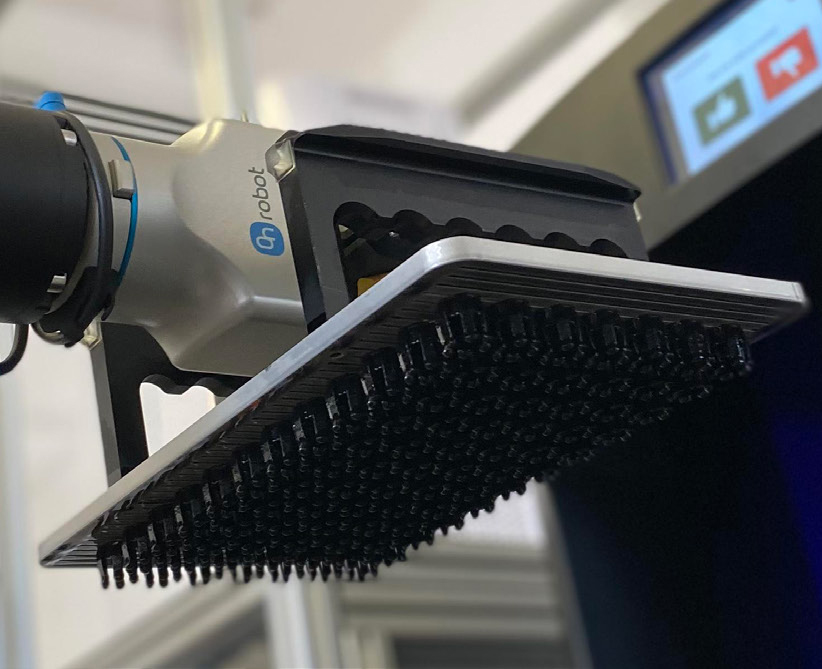

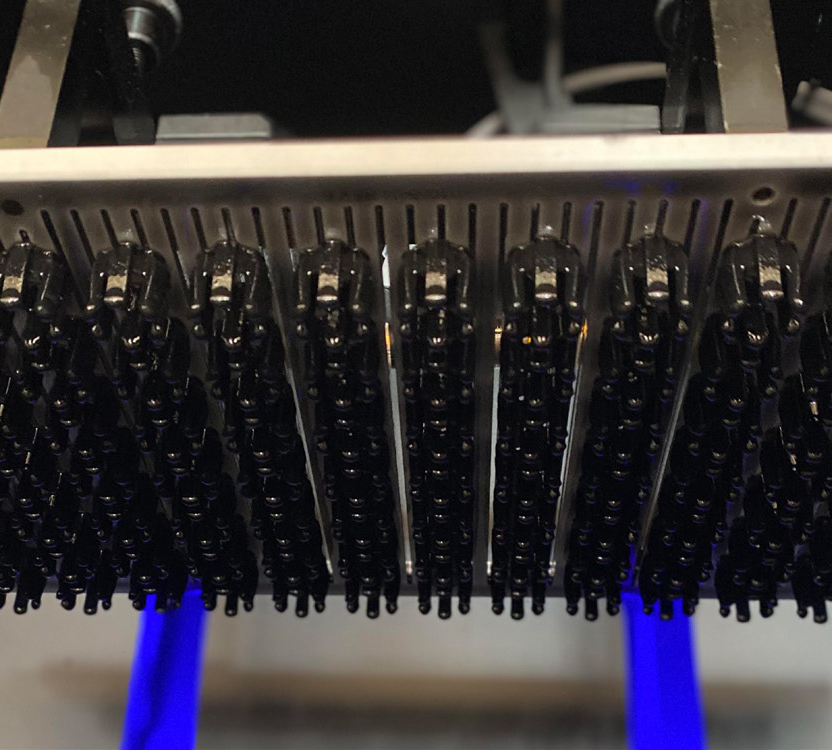

After much investigation, the team landed on Nexa 3D’s additive manufacturing platform paired with robotics and sensoric for its speed, resolution, and flexibility to cater to numerous Europe-based companies. Operating as a production 3D printing service bureau via Nexa3D’s AM system, MaxResolution3D’s customers span a variety of industries, targeting especially those who are in need of small, complex, polymer components in production quantities.

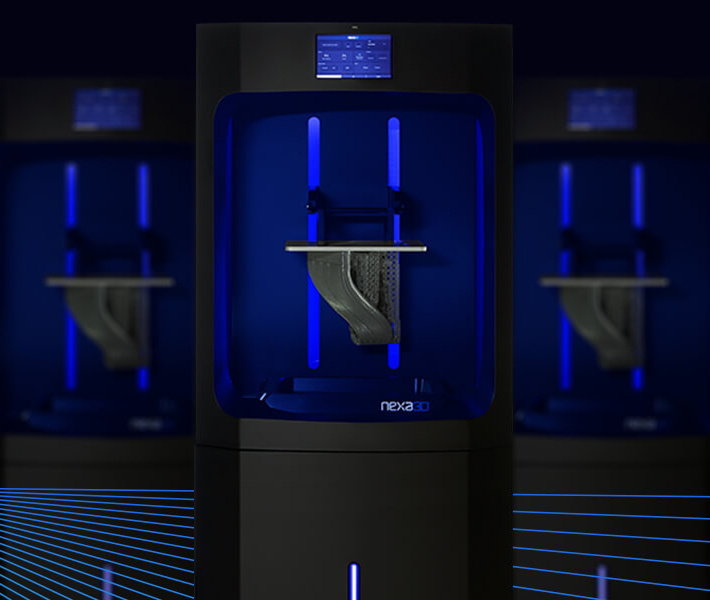

NXE 400 Platform Proved to be the System of Choice

“With our NXE 400 3D printer, we’re able to keep up with our customers’ demands, which he simply could not achieve with one FFF printer. Because of the fast 3D printing our Nexa3D machine offers, it’s easy for us to have on-demand manufacturing available to our customers,” said Dario Dill.

“Compared to other printers we looked into, the Nexa3D NXE 400 offered nearly perfect surface finish, very comparable to the original CAD model, requiring very little post-secondary work,” Männel added.

One of the factors that largely swung in favor of the NXE 400 came when Dario and Max saw a robotic work cell; engineered by Nexa3D’s German partner, ProductionToGo, for handling part loading and secondary operations. One of their long-term goals as a company is to leverage similar robotics to further automate batch production with their NXE 400 system.

“Compared to other printers we looked into, the Nexa3D NXE 400 offered nearly perfect surface finish, very comparable to the original CAD model, requiring very little post-secondary work.”

Max Männel – Co-founder, MaxResolution3D

MaxResolution3D Team Has Grand Plans to Expand NXE 400 Platform

“Having robotics integrated with the workflow is something we value highly; nearly everything we’re doing manually today we hope to automate in the future,” said Dario Dill, Operations & Digitization Lead, MaxResolution3D. “Additionally, we have a polymer scientist on staff who’s helping us with the experimentation and implementation of various resins and other plastics into our existing material stack.”

With only a year of history with MaxResolution3D, Dario and Max are hard at work landing and expanding onto their current production resin 3D printing partnerships all across Europe. In years to come, the team plans to expand into different geographies, a wider array of industries, and with a larger selection of material offerings. It all started with a single NXE 400 installation.

Download Case Study