Keystone Industries Says ‘Incredible’ Speed of NXD 200 Spells Profit for Busy Dental Labs

As one of the most trusted open-source resin suppliers in the industry, Keystone partners with 3D printer manufacturers, rigorously validating each printer to ensure it meets the necessary accuracy and quality parameters. Nexa3D’s NXD 200 not only met Keystone’s criteria–it provided a game-changing option for the dental industry.

Keystone Industries manufactures thousands of dental products as well as its own KeyPrint line of biocompatible photopolymer 3D printing resins. Its group of dental companies focuses largely on consumable digital, laboratory, operatory, and preventative products. The company is a global supplier, maintaining a diverse network of more than 800 US and international dental distribution partners in more than 70 countries.

Keystone’s KeyPrint soft and hard resins cover a wide range of dental appliances and include diverse applications such as splints, models, surgical guides, and indirect bonding trays.

Increased Demand

Dental labs, Keystone’s customer base, have high volume needs. Adding volume can mean adding more printers–investing in new hardware, increased maintenance and space.

Higher Throughput

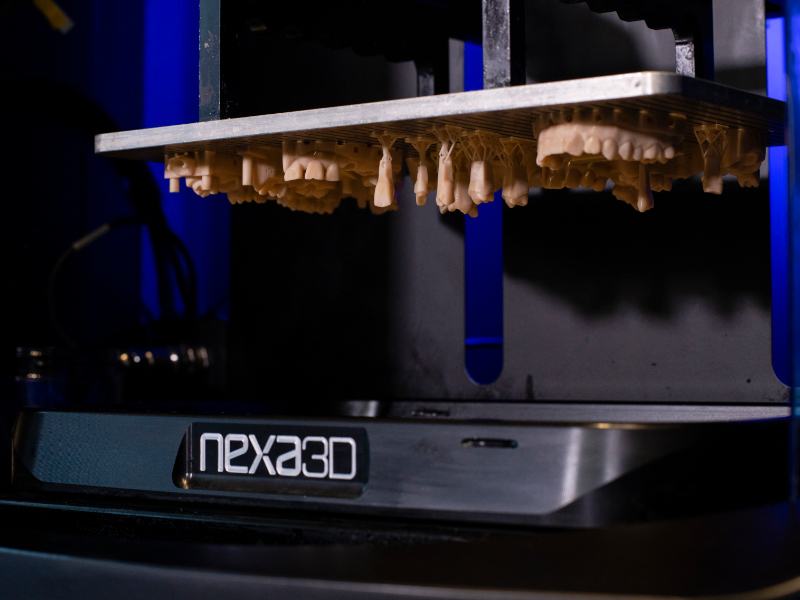

The NXD 200’s large build volume, industrial modular design and lightning speed make it possible for dental labs to increase their throughput to meet demands, with just one printer.

Undeniable Results

Using the NXD 200 Keystone can print 32-36 full arch splints with its KeySplint Hard resin in 76 minutes, and 16 flat dental models with KeyModel Ultra resin in less than 30 minutes.

Ever increasing demands mean labs need to boost production

While the company already works with nearly two dozen 3D printer partners, Keystone faced the challenge of meeting the high-volume throughputs demanded by busy dental labs. Labs make their money by doing the manufacturing for the doctors. While demand for 3D printed dental products continues to surge, the labs are constrained by the size and throughput limitations of their 3D printers.

The simplest solution would seem to be for a growing lab to simply buy more printers, notes Keystone 3D printing engineer and lab manager Benjamin Taylor. But that translates into more expense, more maintenance, and the need for more space. The preferred approach is to use faster, larger-volume 3D printers and to keep them constantly pumping out product.

One printer provides a game-changing scalable solution

Nexa3D’s NXD 200 currently has the biggest build volume in the dental 3D printing market, Taylor says, meaning that lab operators are able to print more product at one time. The NXD 200 platform combines a superior build volume of 8.5 liters (measuring 10.8 in x 6.1 in x 7.8 in), extreme print uniformity, modular design for onsite automation, 4K resolution, and intelligent print optimization software.

In mid-2021 Keystone began evaluating the NXD 200 printer, and as of early 2022 has validated six of its resins for use with the system. The result has been “a game-changer.” With this printer model – which is five to six times larger than many competitive printers – Keystone can print 32-36 full arch splints (depending on the print orientation) with its KeySplint Hard resin in 76 minutes, and 16 flat dental models with KeyModel Ultra resin in less than 30 minutes. Other 3D printers can’t even hold 32 splints on one build plate at a time, Taylor says, so it would take two complete prints to match just one Nexa3D print, part wise. “This is the definition of higher throughput. If you run the printer all day, you’re looking at over 200 splints in an eight-hour day, while other printers would need significantly more time for that,” Taylor notes.

“This is the definition of higher throughput.”

Benjamin Taylor – Keystone 3D Printing Engineer and Lab Manager

Greater output equals increased profitability for dental labs

Additionally, he notes, the NXD 200 “is extremely accurate, offers one of the best print speeds in the market, checks in at an affordable price, and comes with solid tech support.” Powered by Nexa3D’s proprietary Lubricant Sublayer Photo-curing (LSPc) technology, the large build plate and repeatable accuracy of the prints make this 3D printer a viable production-level option that stands to help drive greater output and increased profitability for today’s busy dental labs.

Download PDF