Wilson Sporting Goods Reimagines Product Development Workflows with Nexa3D x Addifab

The long-term play is to continue to utilize this Nexa3D x Addifab platform to continue to churn out new innovations and improvements to existing product lines.

![]()

Wilson Sporting Goods Seeks Better Prototype Injection Mold Tooling

Recently the Wilson R&D/product development team has thoroughly involved themselves in the additive manufacturing space, where they leverage a number of partners to assist with continuous product improvement and innovation. “We’re just barely scratching the surface of additive manufacturing,” says Glen Mason, Manager of Advanced Innovation/Industrialization at DeMarini (a division of Wilson Sporting Goods). “Not only are we looking to accelerate tooling and design iteration cycles, but we’re also looking at how to get to production-ready molds with zero R&D test components needed,” he explains. “Our goal with using Nexa3D’s 3D printer and Addifab’s FIM platform is to fail fast, and not stress ourselves out to get a design precisely right the first time.”

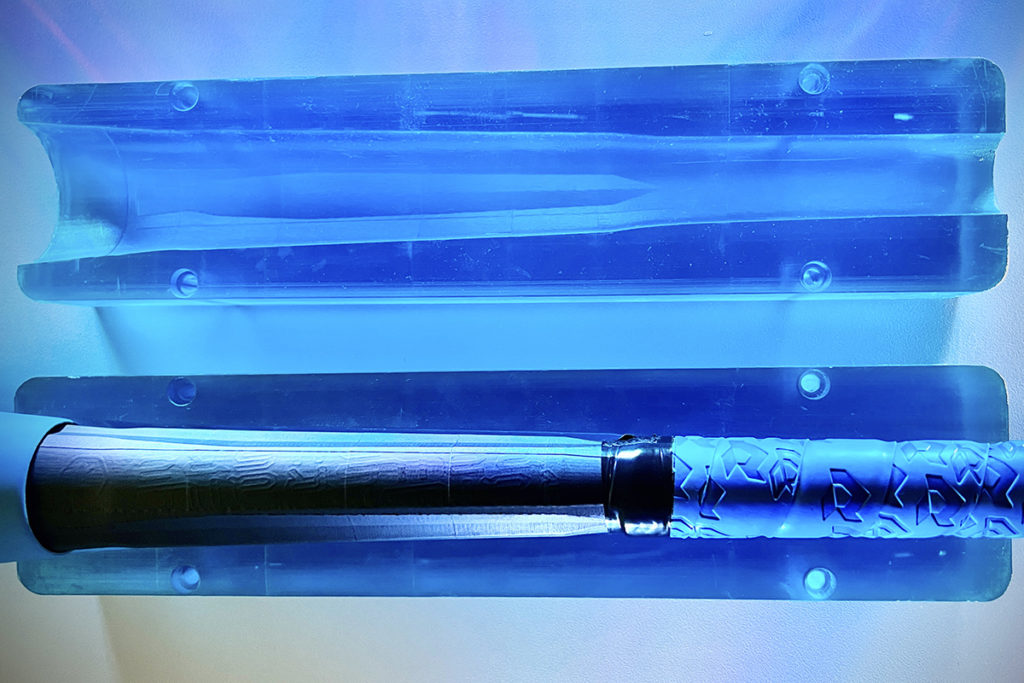

Wilson R&D team was looking for a more effective means to produce prototype injection.

Prior to discovering Nexa3D and Addifab, the Wilson design team was using traditional subtractive manufacturing methodologies to produce their tooling for plastic injection mold prototypes. While metal tooling is typically much more rigid and robust than polymer tooling, there are several design constraints one must consider before delving too far into the concept/design phase of things.

Additionally, with a global manufacturing operation to support, Wilson was also looking for ways to shorten their product design lifecycle, and accelerate their time-to-market to find new ways to

quickly churn out functional and testable prototypes.

Prototyping in a Day, Not Months

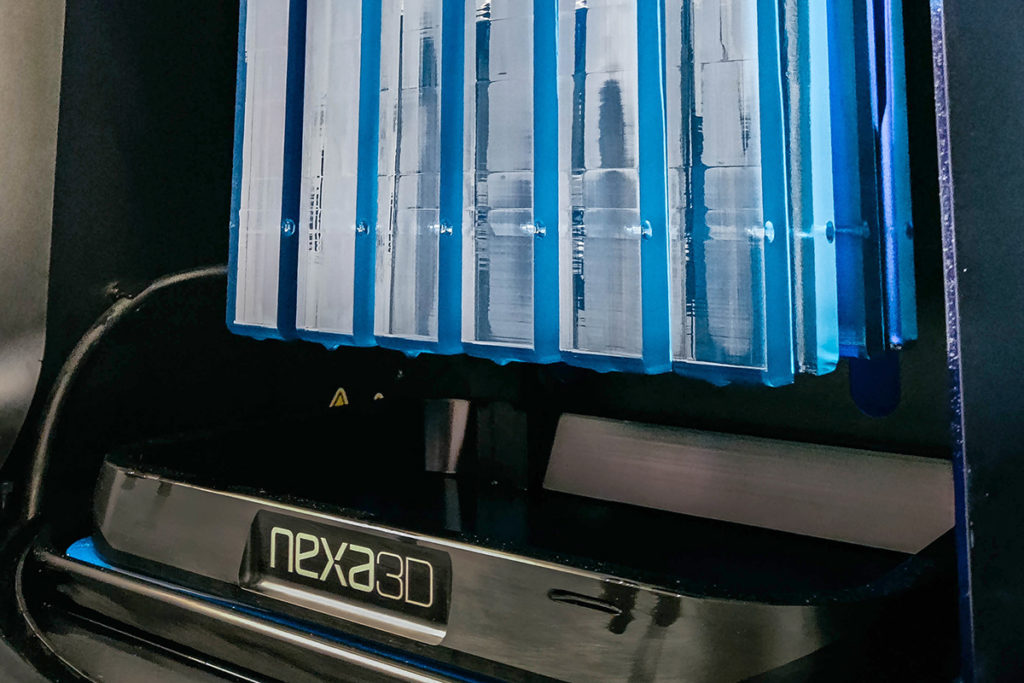

With Nexa3D’s large print envelope and ultrafast LSPc process, the Wilson R&D group can now produce multiple parts at once, in a rapid manner, allowing for multiple design iterations in a single print batch. In addition, what were previously several components assembled together can now be printed into one singular part, reducing assembly time and increasing durability for a given part.

After drafting an initial concept, the R&D team can typically crank out a prototype in a single working day – a process that would have taken months to create previously.

“Because we can iterate so much quicker, print tools faster than we can machine, and eliminate a couple of the steps in the process, our R&D team can afford to be wrong. This helps us to greatly improve our time-to-market, allowing us to be quick and nimble with our design decision-making process.”

Glen Mason

Manager of Advanced Innovation/Industrialization, DeMarini (a division of Wilson Sporting Goods)

Nexa3D + Addifab Create Strong Relationship

The long-term play is to continue to utilize this Nexa3D x Addifab platform to continue to churn out new innovations and improvements to existing product lines. Mason explained that the team is already using this same workflow to coordinate design efforts for adjacent product lines, and will continue to do so. Although it’s quite difficult to replace the durability and capabilities of metal production tooling, the Wilson product development team is constantly pushing the envelope on what’s possible using additive manufacturing as their primary tool.