Unlocking the Advantages of xESD for Electronic Components Carriers Fabrication

Challenge

Long lead times and the costs associated with machined, bespoke semiconductor component carriers prompted the Customer to explore Additive Manufacturing (AM) technologies. The goal was to accelerate new product introduction cycles and avoid instances of having to replace the entire testing equipment due to the redesign of a single component carrier.

The Customer had specific requirements for the AM equipment and material options, including:

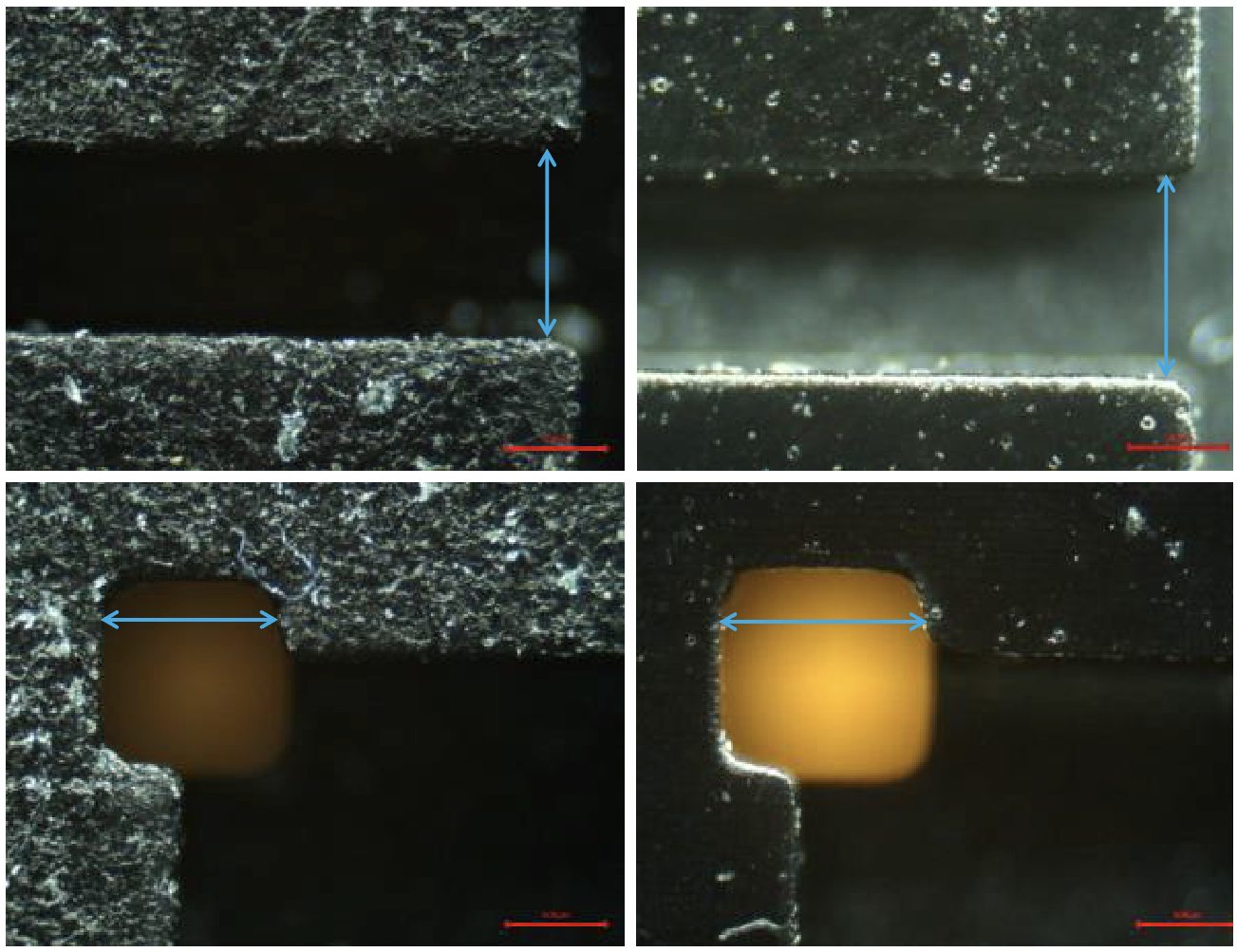

- The ability to achieve an exceptionally high level of feature resolution

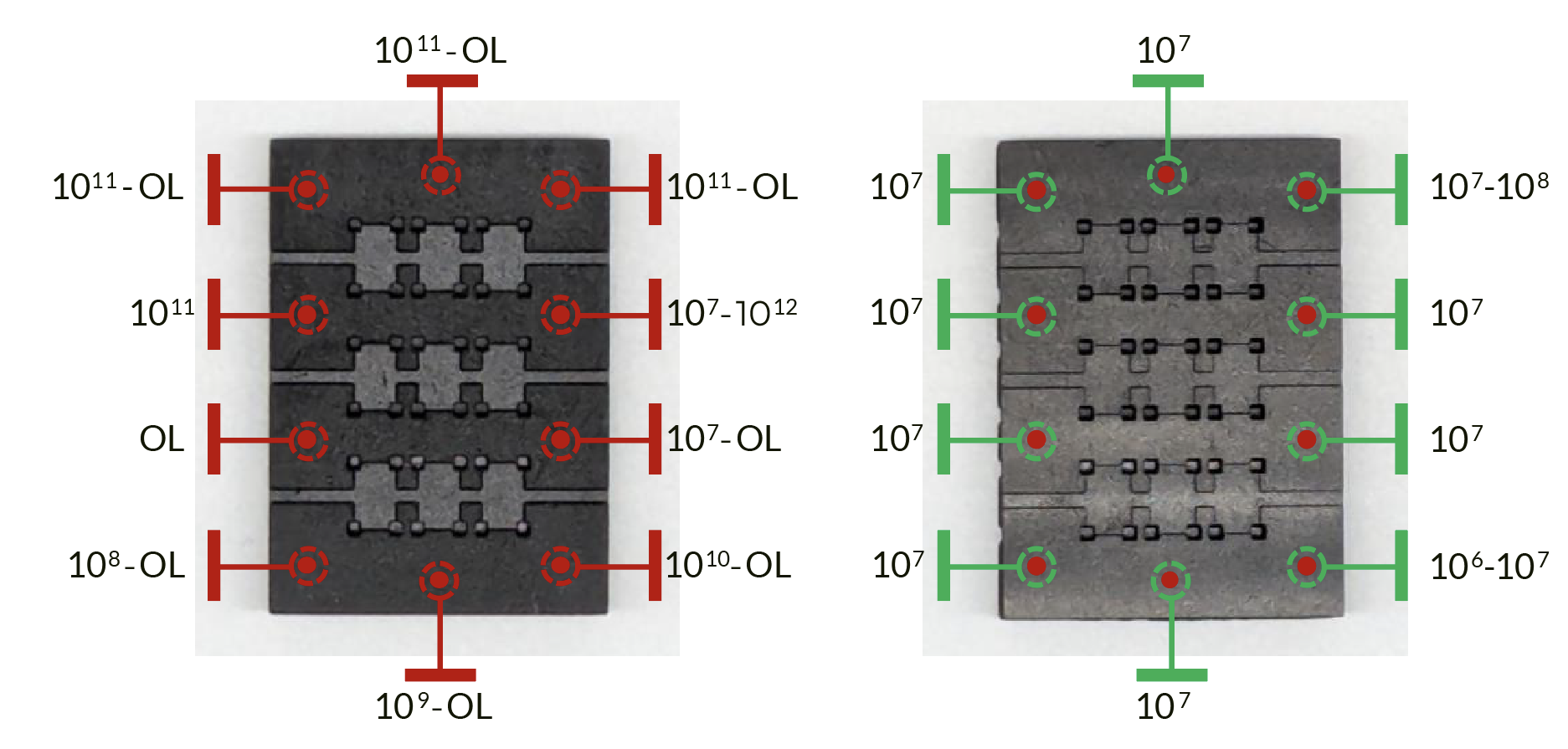

- Static dissipative material capability

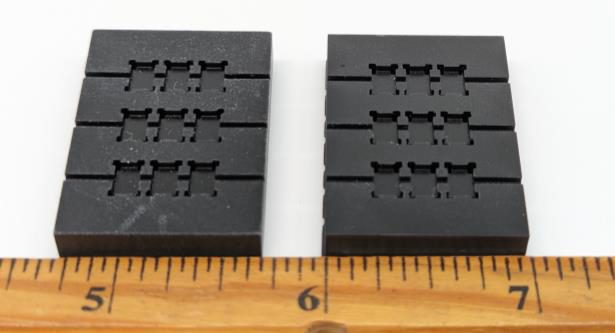

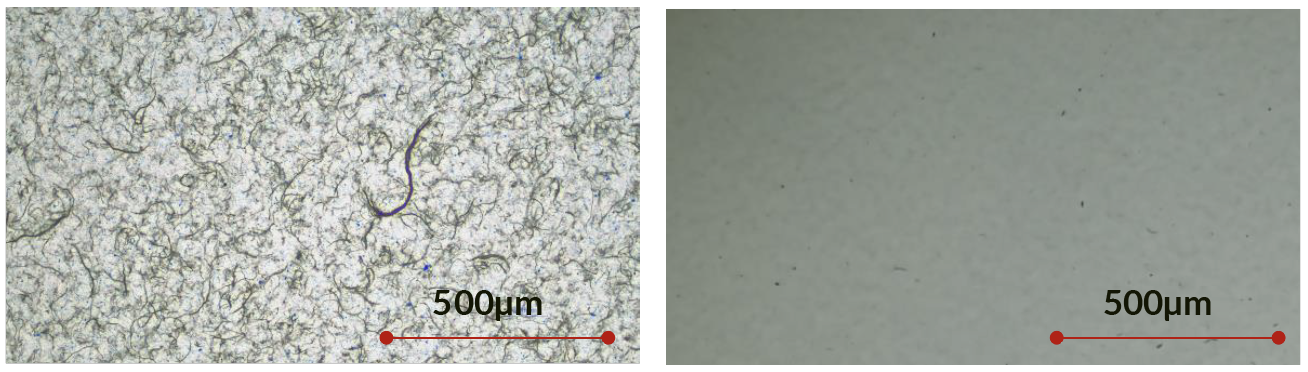

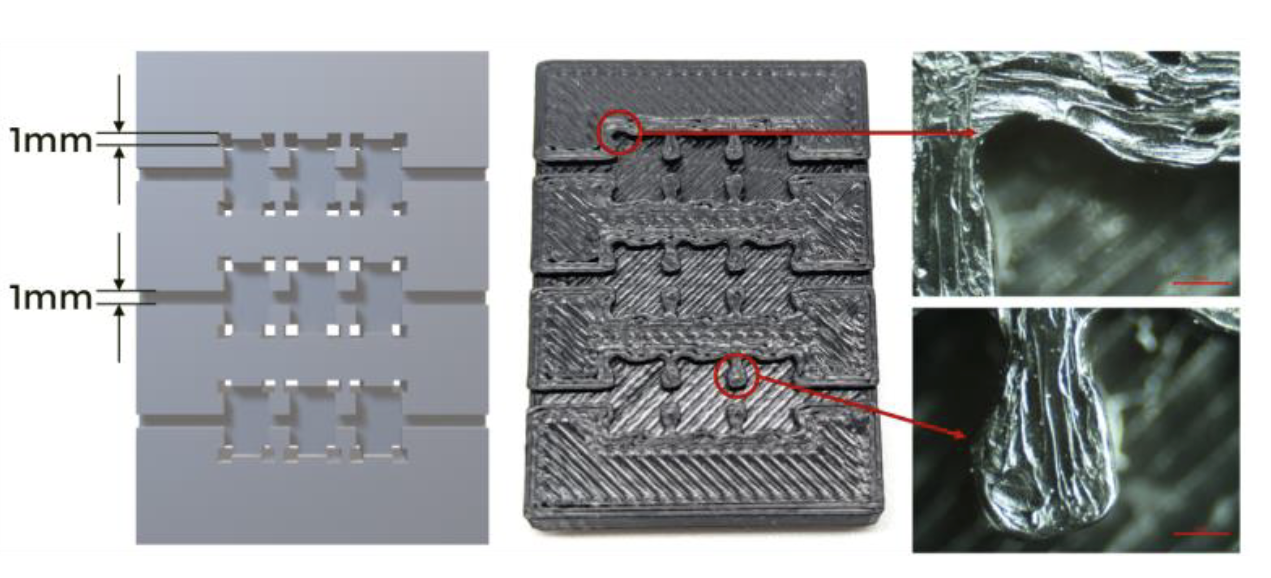

The Customer faced a challenge in finding the right combination of electrostatic discharge (ESD) materials and AM equipment. The options they previously explored relied on filament-based AM, but these options were unable to meet the intricate feature requirements. The capabilities of Fused Filament Fabrication (FFF) equipment, as shown in Figure 1, were not sufficient to achieve the necessary level of precision. As a result, the components produced by FFF machines were unusable. Consequently, the Customer actively sought out an alternative AM process capable of accommodating both high resolution and ESD requirements.

Figure 1: CAD model of the part and the slightly modified version built using FFF. Photo of the FFF part shows inadequate resolution of the features, which renders parts unusable.

Customer

Confidential customer (“Customer”) is a manufacturer of ultra-miniature semiconductor components for medical, aerospace and defense, and industrial markets.

Industry

Semiconductor

Technology

Vat Photopolymerization

Material

xESD

Challenge

- Long lead times & cost for bespoke semiconductor component carriers

- Inability of FFF to achieve necessary precision levels

- Use xESD and XiP for part

fabrication

Solution

Results

- Nano-Uniform ESD performance

- Exceptional feature resolution

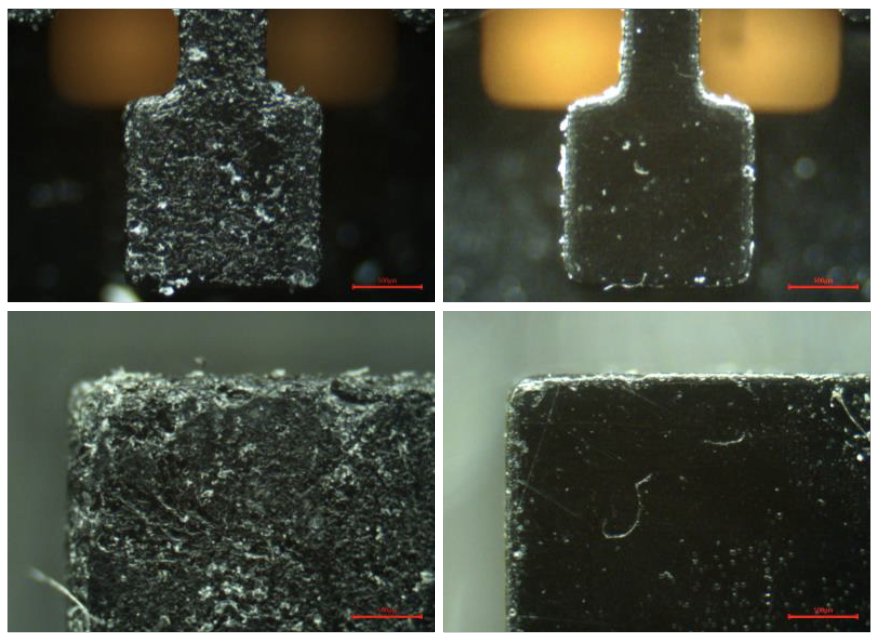

- Outstanding surface finish

Impact

- Reduction in lead time from

8 weeks to 2 hours - 84% cost reduction

- Higher-accuracy parts with finer

detail and resolution