Part Design

This part design was provided by a premier global automotive manufacturer based in Germany. For FIM, STEP files are preferred.

Insufficient spare parts inventory.

Use FIM to produce spare parts using customer-specific material,

BASF Ultramid® 30% glass-filled PA66.

This part design was provided by a premier global automotive manufacturer based in Germany. For FIM, STEP files are preferred.

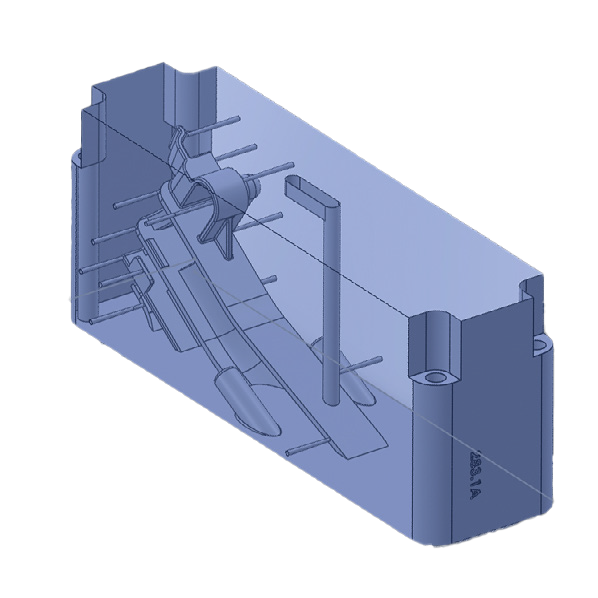

The next step is converting the STEP file into a mold design which is done by inverting the part into a cavity, in a block of material, and then adding the inlet gate(s) and initial venting.

The part design was large, so the mold was split into 2 mold units and assembled.

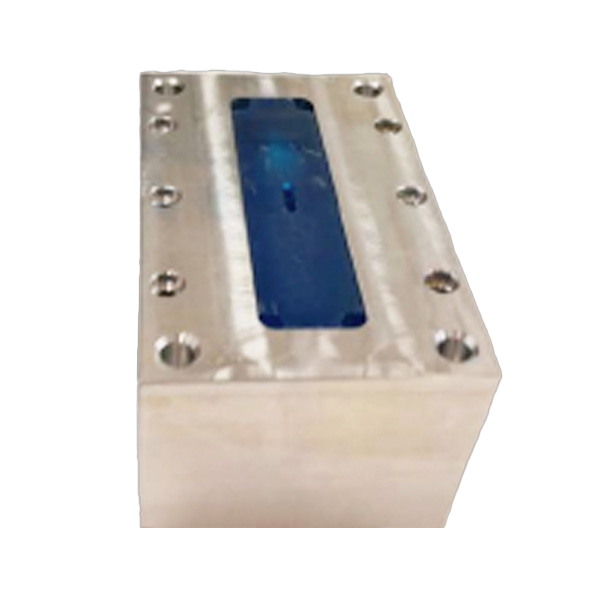

The parts were molded on a 50-ton press. FIM molds work hand-in-hand with any installed base molding unit.

An aluminum mold frame was used to hold the large mold assembly in place.

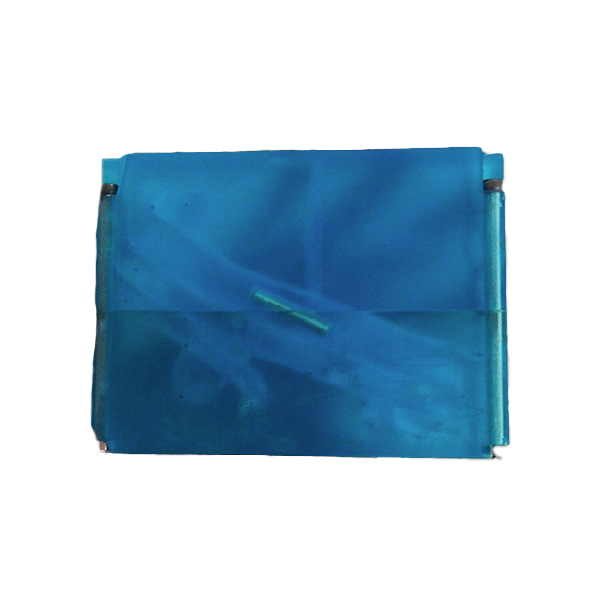

The Nexa3D alkaline solution was used for demolding these parts, over a 2.5 day period.

This time can be optimized through mold re-design or by removing a part of the mold before demolding.

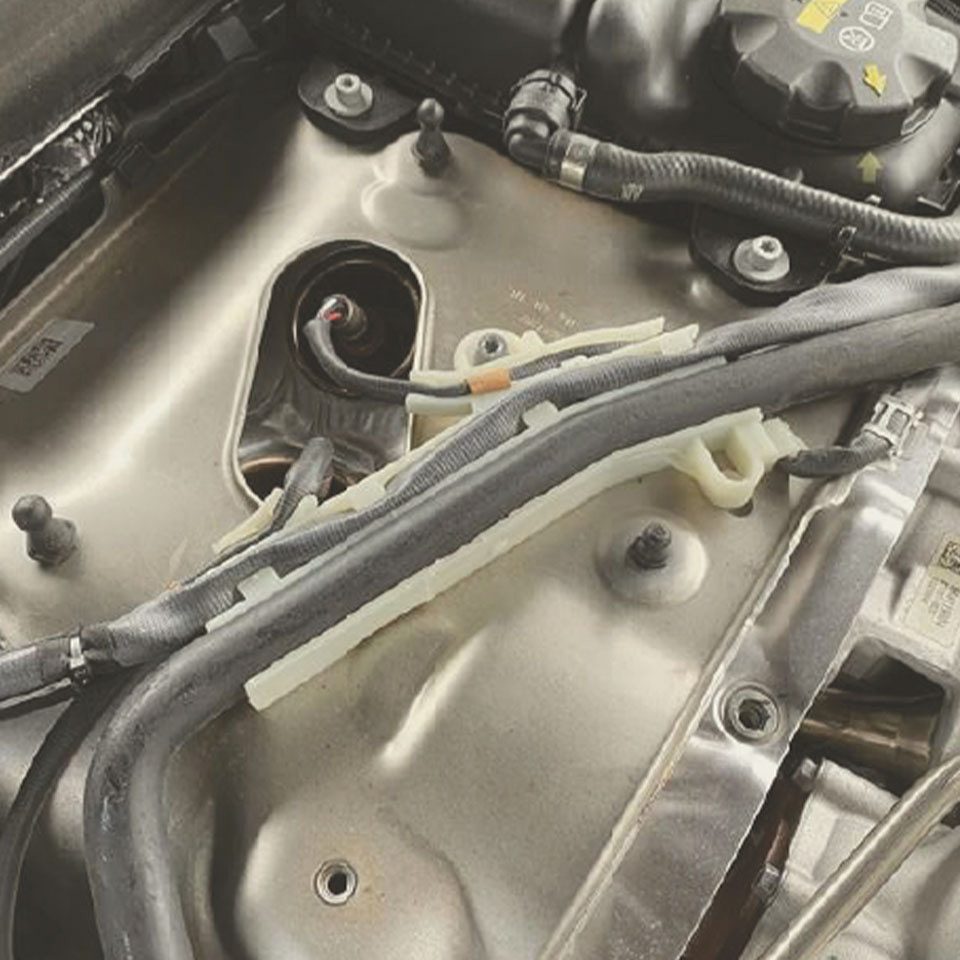

The bracket above is straight out of the tool: no post-processing, no polishing. Details in the design and part functionality stand out clearly.

The parts were mounted in a range of high-end sports cars.