Part Design

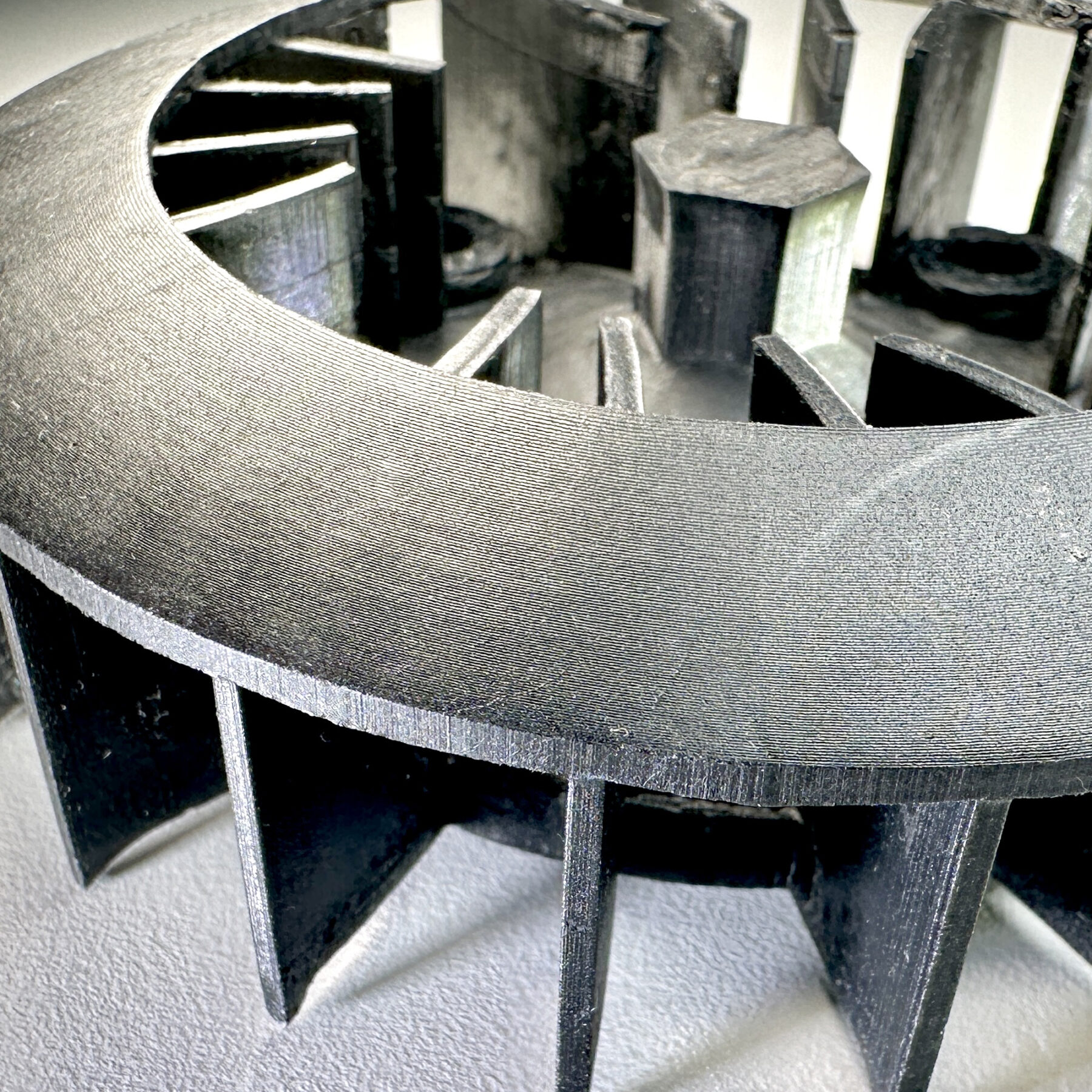

The design focused on durability and precision, leveraging the strength of PA6 with 30% glass fill.

The existing replacement fan wheels were not meeting customer quality expectations, with parts often breaking within the first year. A more advanced solution was needed for higher durability.

By using a high-performance material injected into 3D printed xMOLD cavities, SK Industriemodell could create a superior quality spare part.

Explore Timeline

The design focused on durability and precision, leveraging the strength of PA6 with 30% glass fill.

The two-piece mold was printed in 2 hours and 53 minutes on the XiP Desktop 3D Printer, consuming 677 ml of xMOLD resin.

The demolding process took 2 days, allowing for careful extraction of the final part.

The entire 3D printed mold was ejected from the metal tool frame with a single ejector pin, and the part was transferred to the dissolving station for mold dissolving.

The new approach demonstrated significant improvements in part quality and durability, meeting customer expectations for a longer-lasting product.