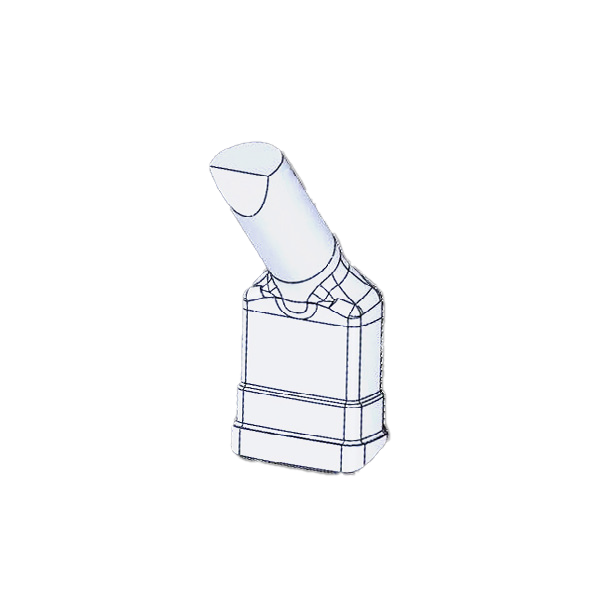

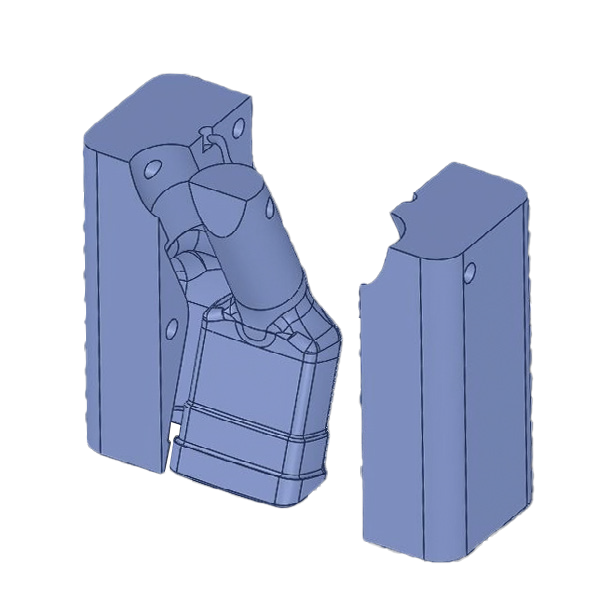

Part Design

The adapter was designed as designed in partnership with Medical Officer Michael Mølmer to connect the mask to a HEPA air filter.

The part was the perfect fit for the divers mask while in a medical grade material that needed to maintain it’s quality and performance after repeated sterilization.