Part Design

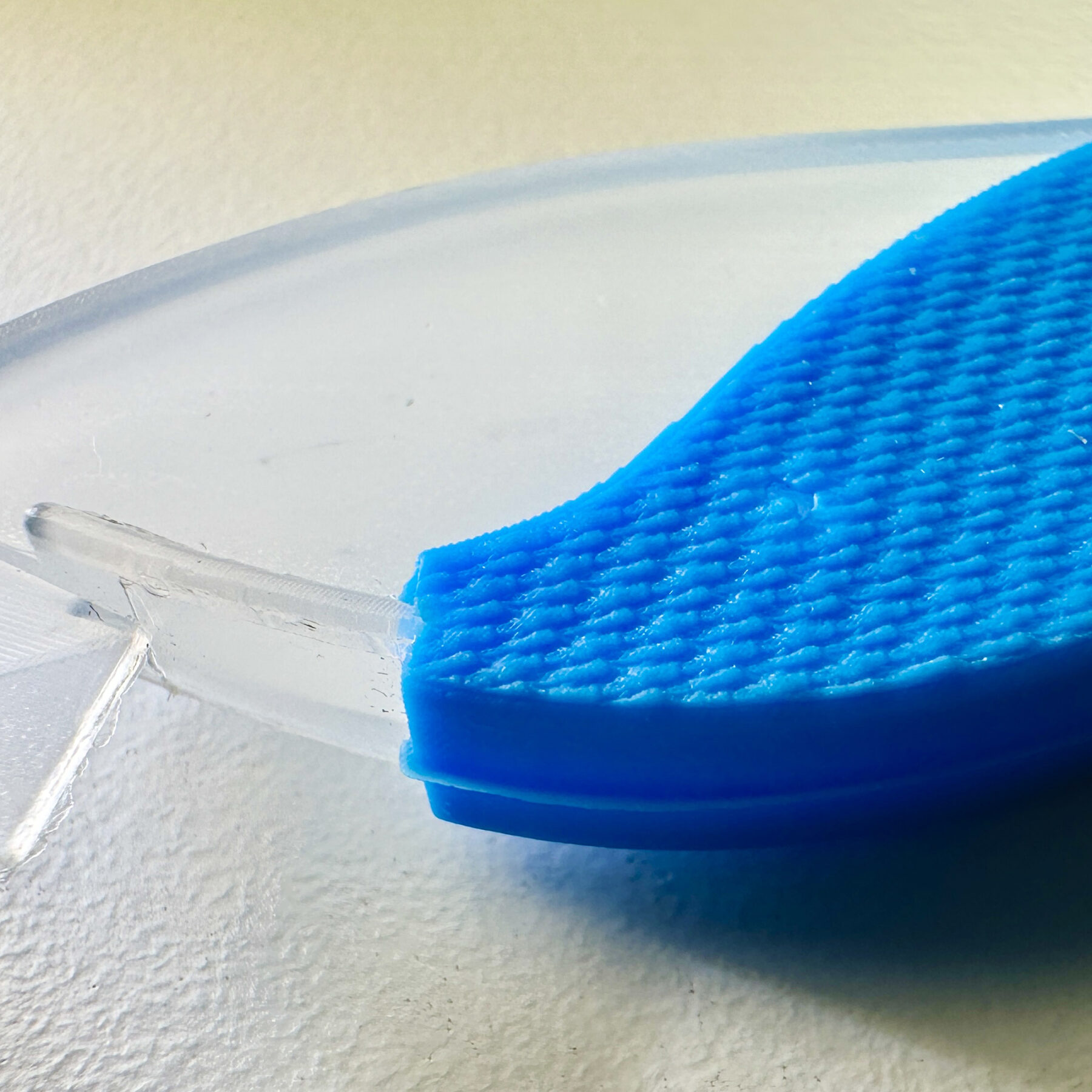

Spacers were added to ensure stability during overmolding. Iterations were closely observed.

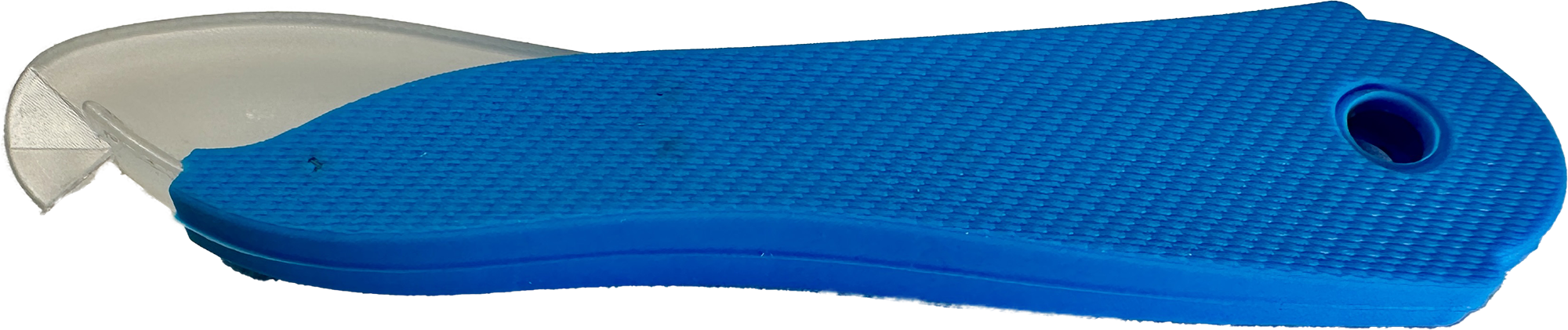

Starting with an idea, CAD drawings were developed without initially printing the part. The focus was on creating a functional part for injection molding, ensuring strong adhesion between the rigid core and soft handle.

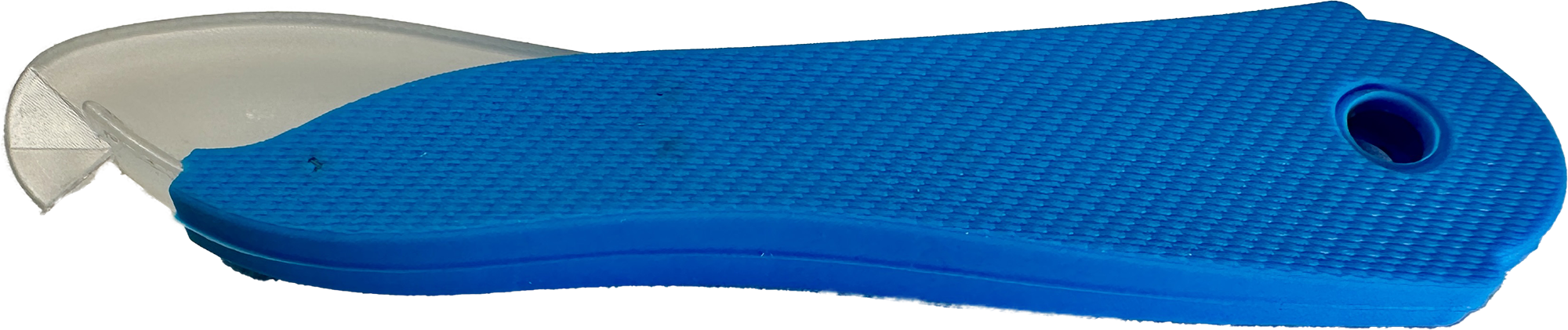

The development process led to a solid product design, ready for steel tooling with confidence. The case highlights the importance of early iterations for validating concepts.

Explore Timeline

Spacers were added to ensure stability during overmolding. Iterations were closely observed.

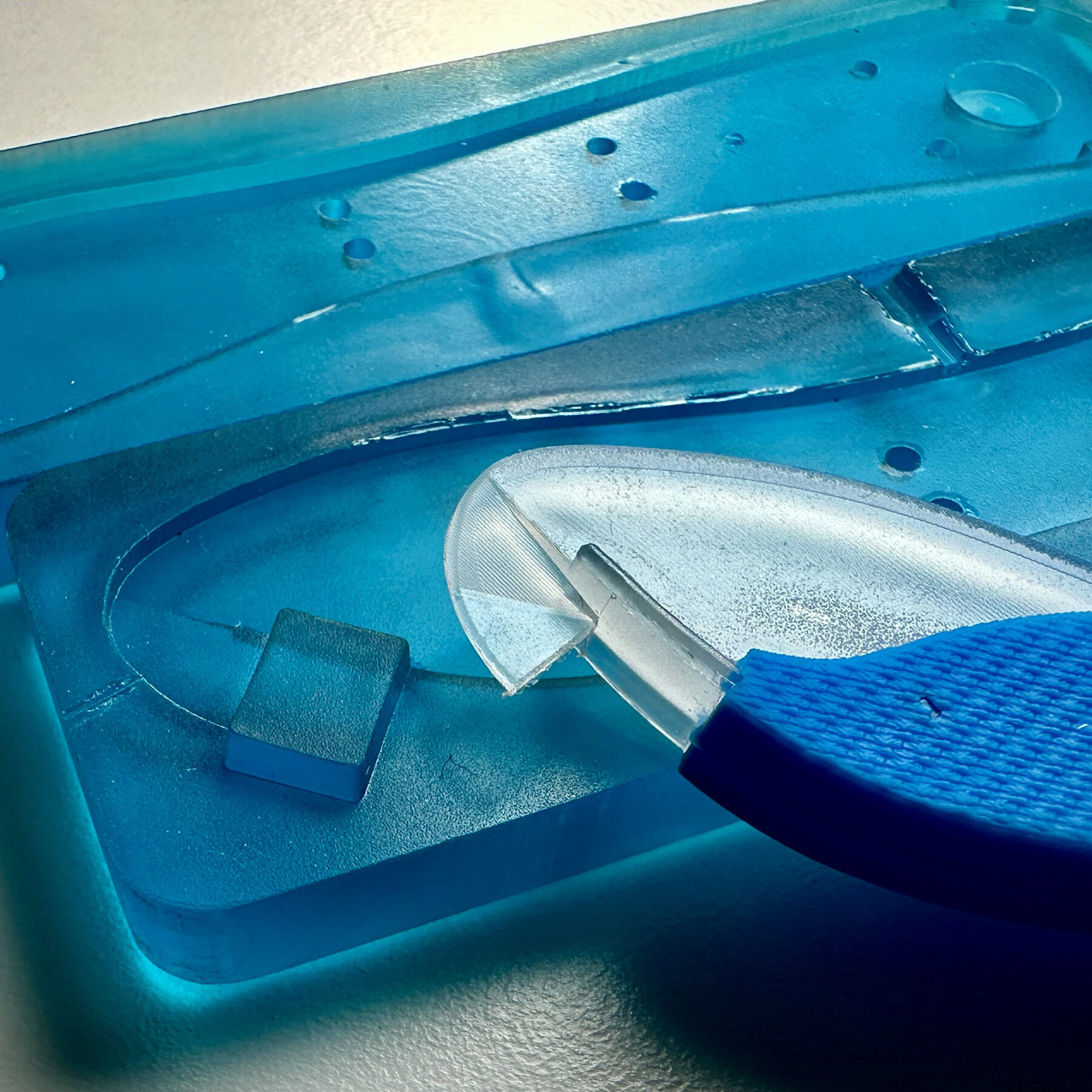

Mold design was completed in 30 minutes. Foil was applied to the printed mold, which was later used to replicate the design in steel tooling.

Print time was 1 hour and 2 minutes for all four tool halves

First parts were ready within 5 days, significantly faster than conventional tooling.

The fast iteration process helped ensure confidence in the final design before transitioning to steel tooling, showcasing the efficiency of the approach.