Freeform Injection Molding

Injection-molded parts in days instead of weeks, with no hard-mold investments

FIM = Unlimited Material Options

With Freeform Injection Molding, you no longer have to compromise when selecting what materials to use in your prototyping process. xMOLD parts have been proven across the entire range of thermoplastics, from Polypropylene to PEEK, with fillers including glass and carbon fibers, ceramic and metal powders, and a range of other additives.

FIM = New Levels of Design Freedom

Freeform Injection Molding lets you manage undercuts and other complex part features with ease. Replace sliders, cores and other mechanical complications with soluble FIM molds and FIM elements for simpler mold designs and shorter lead times. Or break new design ground with products boasting impossible-to-mold features.

FIM = Low-Volume Support for the Life of Your Product

A product that is developed with FIM is also a product born with seamless scalability. From batches of one in the prototyping phase through customized variants as the product scales to spare parts on-demand at the end of the product lifecycle, FIM provides a no-minimum-orders guarantee. And when demand climbs, and higher volumes are needed, xMOLD elements integrate with conventional metal molds to provide you with the means to scale.

“Freeform Injection Molding is a transformative technology that promotes rapid and cost-effective innovation. There are many invaluable benefits of FIM including complete design freedom, functional realism, extensive material options and final physical characteristics which enable advanced R&D capabilities without the traditional constraints.”

– Ky Layfield, Sr. Packaging Development Engineer, the Coca-Cola Company

How Does Freeform Injection Molding Work

CAD to molds in hours, to parts in days

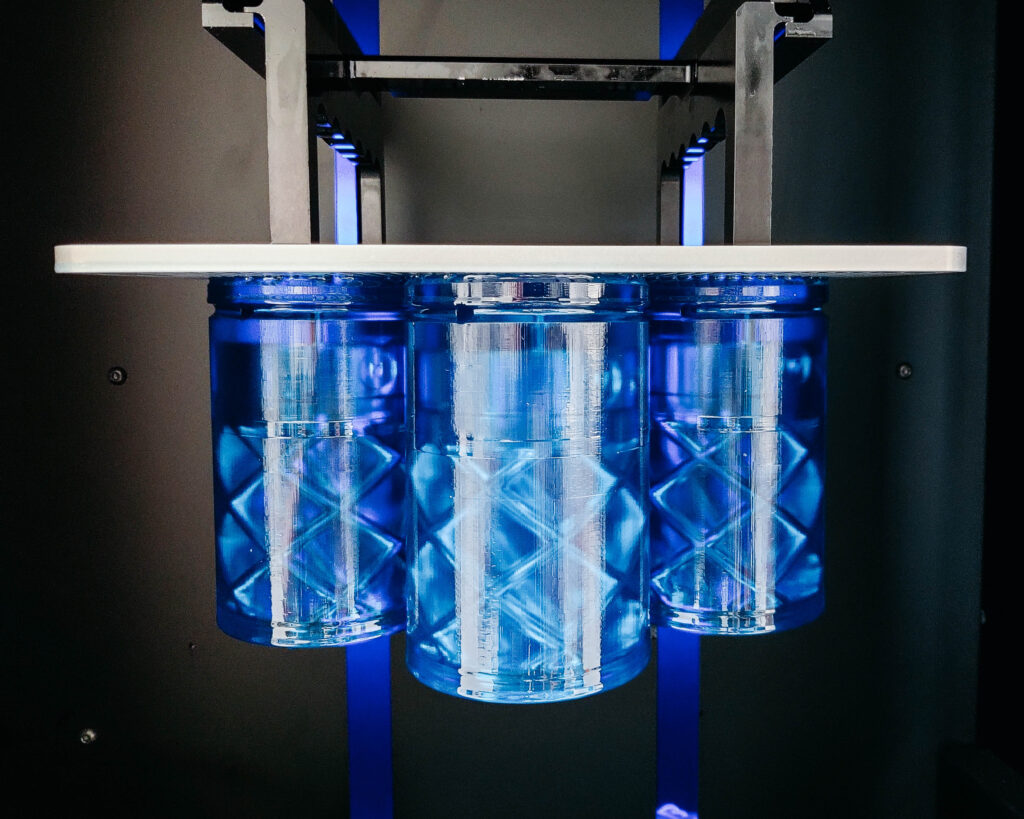

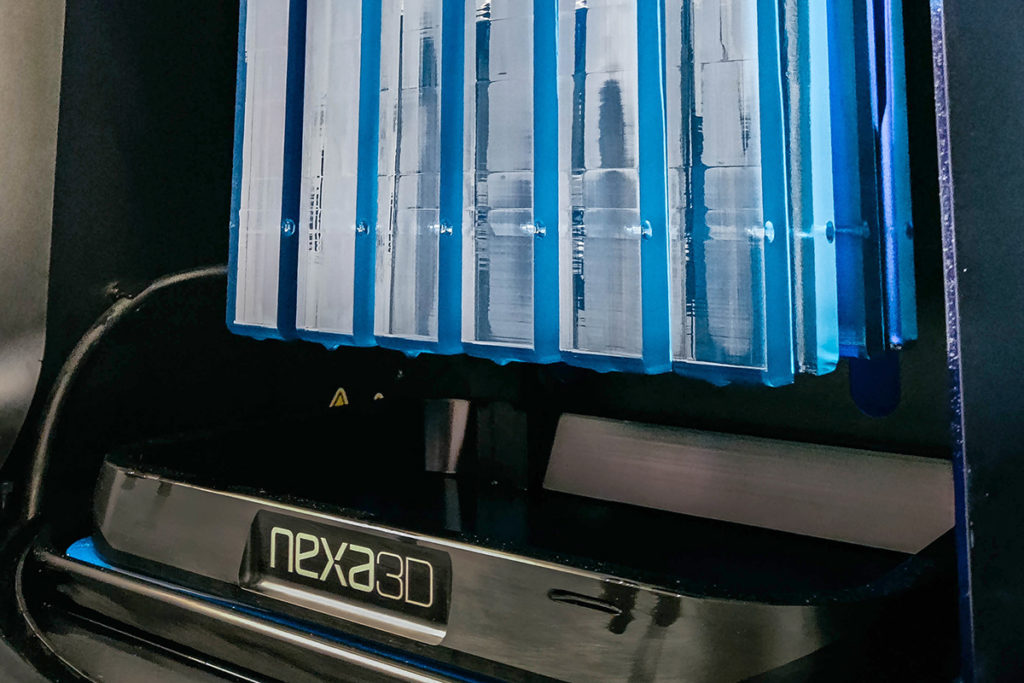

Combining the speed and throughput of Nexa3D’s LSPc printers with the versatility and design freedom of xMOLD resin means that you can go from design to complex injection-molded parts in a matter of days. Accelerate design cycles, slash your R&D costs, and get to market faster with digital molds from Nexa3D.

Wilson Case Study

With Nexa3D’s large print envelope and ultrafast LSPc process, the Wilson R&D group can now produce multiple parts at once, in a rapid manner, allowing for multiple design iterations in a single print batch.

View Case Study

![]()

The Complete Desktop FIM Package

- XiP Desktop 3D Printer

- xWASH FiM & Wash+Cure

- APSX PIM Molding Unit

- xMOLD Resin (5kg)

- XiP Build Plate

- Evercare Service Plan (1 year)

- FREE—Mold Generator Software (1 year)

$29,912

[Download] Design Guide for 3D Printed Tooling

Freeform injection molding combines the freedom of 3D printing with the reliability and quality performance of conventional injection molding. A complex tool is printed using a dissolvable xMOLD resin that is compatible with the actual molding feedstock to create prototypes and production parts in final grade plastics – within hours and at a fraction of conventional tooling costs. This comprehensive guide will walk you through all the design considerations and guidelines to optimize your 3D printed tool design.

Download NowGo from CAD to Production in Hours Instead of Weeks

Digitalized injection molding enabled by xMOLD resin allows you to print molds that are compatible with the entire range of injection-moldable materials, and with a design freedom previously only available with 3D printing.

Print traditional molds for higher volumes, or soluble molds to speed up manufacturing of complex parts in challenging materials

Skip the machine shop – just hit print and go

-

Cut tooling costs by 96%

-

Iterate more frequently and quickly

-

Prototype for production, in the materials of your finished product

Contact us today to learn more!