Medical

Our 3D printer for medical applications means truly rapid prototyping! Every year, 3D printing offers more and more applications in medical fields. Helping to save and improve lives in ways never before imagined. As we’ve seen with COVID-19 and global supply chain shortages, 3D printing offers a reliable and efficient way to supply the medical and healthcare field.

Nexa3D technology has been helping the medical industry own more of its supply chains

Work quickly and efficiently to address real needs in real-time — often in minutes! Our 3D printer for medical devices and applications can help in the rapid prototyping and manufacturing of:

- surgical equipment

- diagnostic tools

- face masks and shields

- prosthetics and implants

- patient-specific replicas

The medical and healthcare industries are the largest end-users of 3D high-performance printing materials.

The global healthcare 3D printing market size is forecasted to be growing at a CAGR of 18% between 2020 to 2025.

3D printing in the medical field is projected to be worth $3.5B by 2025 as compared to $713.3M in 2016.

Market pressures and real-life emergencies don’t respond well to lag time!

Nexa3D takes 3D printing technology in healthcare spheres to the next level, accelerating rapid prototyping for agile product development, reducing time-to-market lead time, and allowing companies in the medical industry to meet demand for customization, while remaining in compliance and adhering to safety regulations.

- Design more: explore all your ideas and bring them to life in minutes.

- Develop more: condense your design cycles to get to market faster than ever before.

- Save more: design, print, test, iterate and validate prior to investing in extensive production solutions.

- Manufacture or customize more: respond swiftly to any market challenges, making millions of same or customized parts.

We’ve partnered with Henkel to introduce a high-impact, durable material for medical devices!

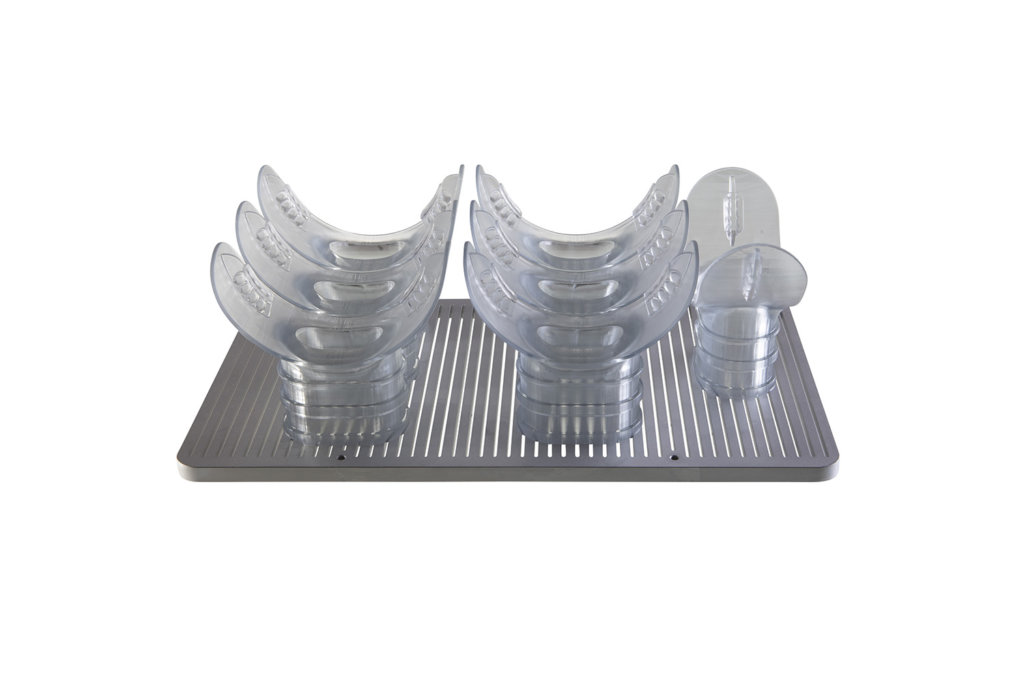

Our partnership with Henkel, a leading supplier of high-impact functional additive materials, has allowed us to quickly tailor, tune and test a new polypropylene-like material, xMED412, which is ideal for manufacturing a variety of biocompatible, medical, and wearable devices.

Read More

This lightweight yet sturdy material:

- is designed to withstand impact, moisture, and vibration

- comes with inherent insulating properties

- can be machined, tapped, or polished to deliver desired production finishes

These highly desirable attributes are ideal for devices that might need to be sterilized or disinfected and that must be shipped around the world for use in home care and healthcare settings.

xMED412 combines the physical properties and biocompatibility of medical-grade materials and is ideal for the production of various devices across industries. This 3D printing medical technology could be used to speed up surgical procedures, produce less expensive versions of required surgical tools, and improve the lives of those reliant on prosthetic limbs.

Book a Meeting