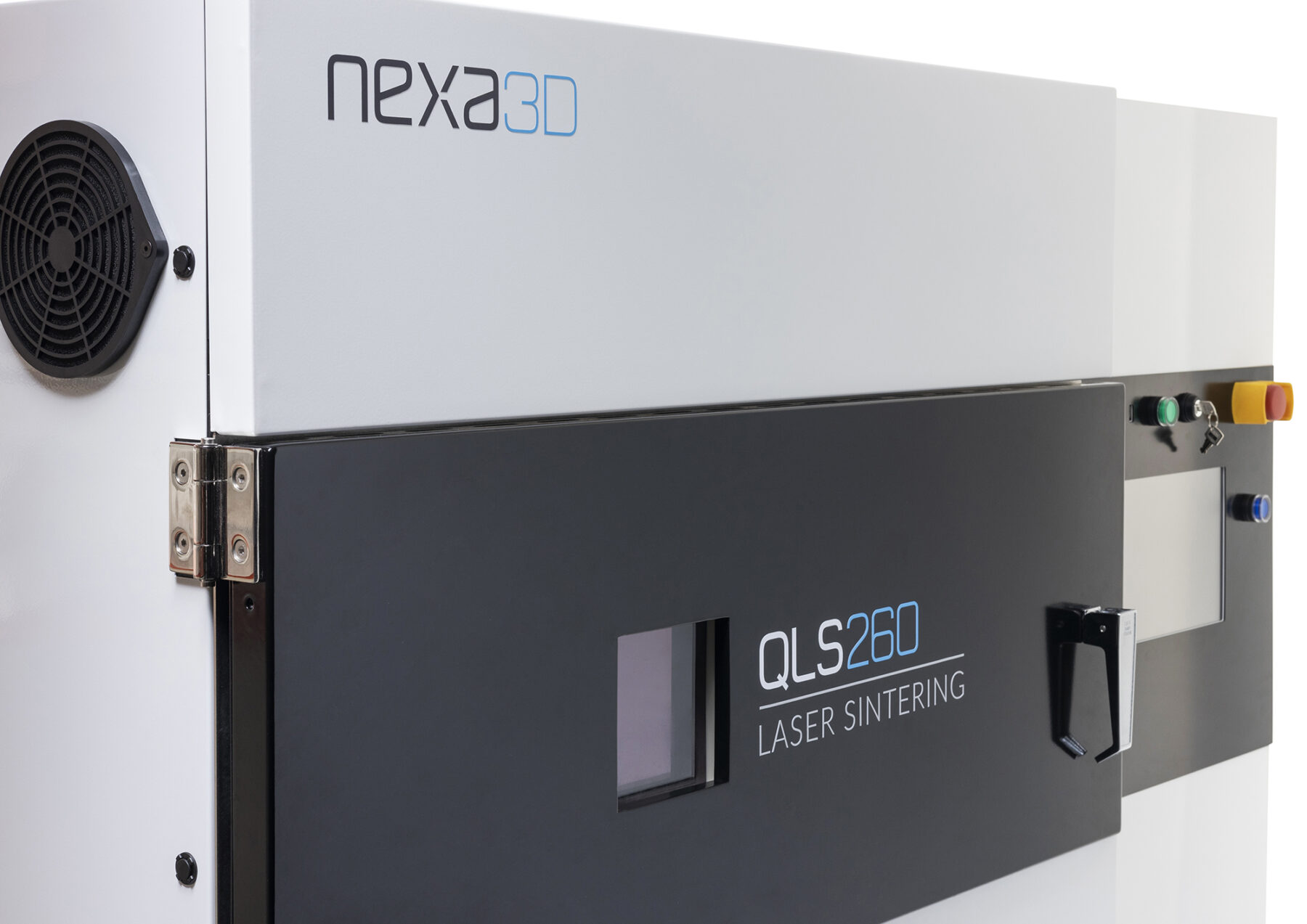

Fast Cycle SLS 3D Printer

QLS 260 is an open platform selective laser sintering (SLS) 3D printer with an unrivaled 21 hour cycle speed. It uses a single 60 Watt CO2 laser to produce prototypes and production parts with robust mechanical and thermal properties. In addition to a broad range of high-temp thermoplastic and metal materials, it also excels with recycled waste powder from other technologies like multi jet fusion.

Increase Daily Output

With industry-leading cycle time of just 21 hours where the required cooling period is only 2 hours, the QLS 260 is a productivity powerhouse. It uses a single 60 Watt CO2 laser to increase your daily throughput without the need for a lengthy cooling period due to its smaller build chamber.

Material Flexibility

The QLS 260 is an open platform with 16+ qualified materials including a range of Polyamides, PP, PBT, TPU, as well as the patented metal powders from headmade materials®. In addition to the currently qualified materials, it excels with recycled powders from HP and EOS to extend the life of your powders and provide operational sustainability.

Lowest Total Cost of Ownership

With one of the lowest entry points in the professional selective laser sintering market, combined with lower operating costs due to its powder refresh rate of just 20% and use of third party materials, the QLS 260 offers the lowest total cost of ownership for your industrial SLS 3D printing needs.

NEW MATERIAL

TPC Added to Materials Portfolio

Evonik’s recently released thermoplastic copolyester powder, INFINAM® TPC 8008P, is now available for use with Nexa3D’s high throughput QLS-Series powder bed fusion printers.

Specifications

| Technology | Selective Laser Sintering |

| Build Volume | 230 x 230 x 250 mm (9.0 x 9.0 x 9.8 inch) |

| Laser Performance | 60W CO2 |

| Layer Thickness | 0.06 / 0.08 / 0.1 / 0.15 / 0.2 / 0.3 mm |

| Max. Build Speed | Up to 22 mm / hour (Geometry dependent) |

| N2 System | On-board Nitrogen Generator |

| Accuracy | 0.2mm |

| Full Parameter Access | Yes |

| Printer Dimensions | 148 x 85 x 204 cm (58.3 x 33.5 x 80.3 in) |

Download Brochure

“[This] is the first industrial quality SLS printer at a sub-industrial price point. It paid for itself in the first three months.”

Umang Dua

President of TrySight

“[This printer] has proven itself to be a dependable workhorse, consistent in detail and reliable in performance. It allows us to focus on what matters to our customers, and that’s the reason we’ve chosen to expand our fleet to six machines.”

Josh Stover

Co-Founder of 3D Printing Tech

NEW MATERIAL

Metal 3D Printing with ColdMetalFusion

Excited to announce our partnership with Headmade Materials and enable metal 3D printing capability via ColdMetalFusion on all of our SLS platforms!

With the addition of metals, the QLS series printers offer the most flexible, affordable, and scalable industrial SLS solution for both polymer and metal part production.

Open Material Platform

Your production capabilities with the QLS 260 are nearly limitless thanks to its open material platform, wide-use temperature range, and inert processing atmosphere. From common filled and unfilled nylons to rugged polymers like PBT, the QLS 260 is compatible with a versatile range of materials to ensure that you’ll have the right material for the job.

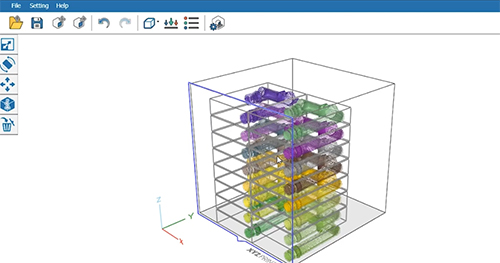

Intuitive Software

QLS 260 is powered by two advanced software suites, NexaX for QLS. NexaX for QLS controls the sintering process and allows users to start and monitor jobs remotely.

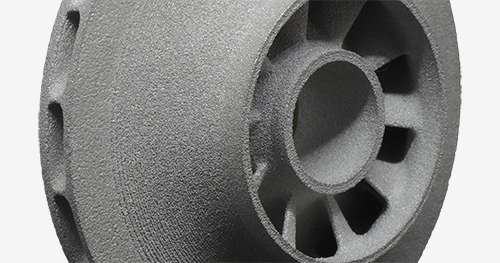

Cold Metal Fusion Compatible

Cold Metal Fusion by headmade materials® is a patented process that combines the advantages of fast cycle sintering with established powder metallurgy processes to create titanium and steel parts. Using a polymer-coated metal powder, the QLS 260 produces ‘green’ parts in a low temperature processing environment. Parts then go through a debinding and sintering process that burns out any remaining polymer and sinters metal particles together to form final metal components.

Ultimate Guide for SLS 3D Printing

Laser Sintering vs. Fusion Sintering—Which Powder Bed Fusion Technology is Best for You?

Download the full guide.