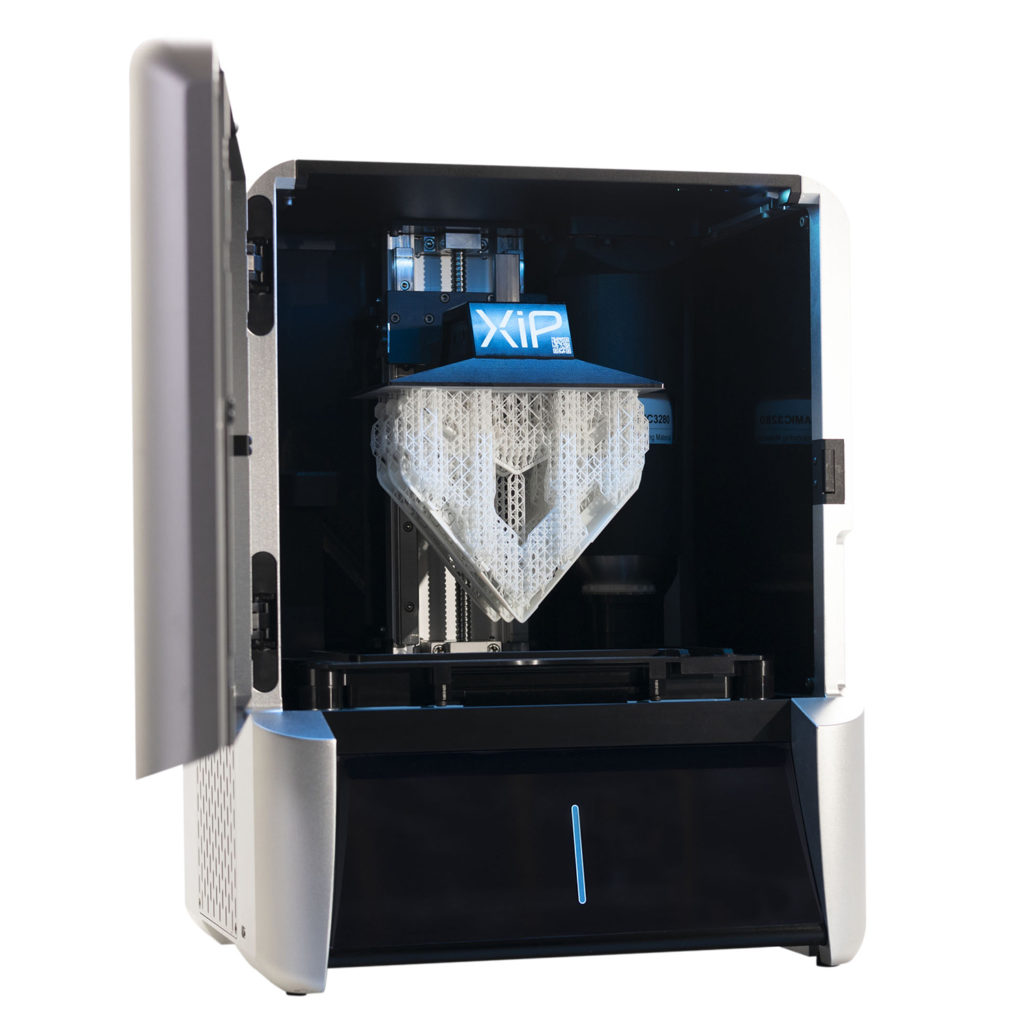

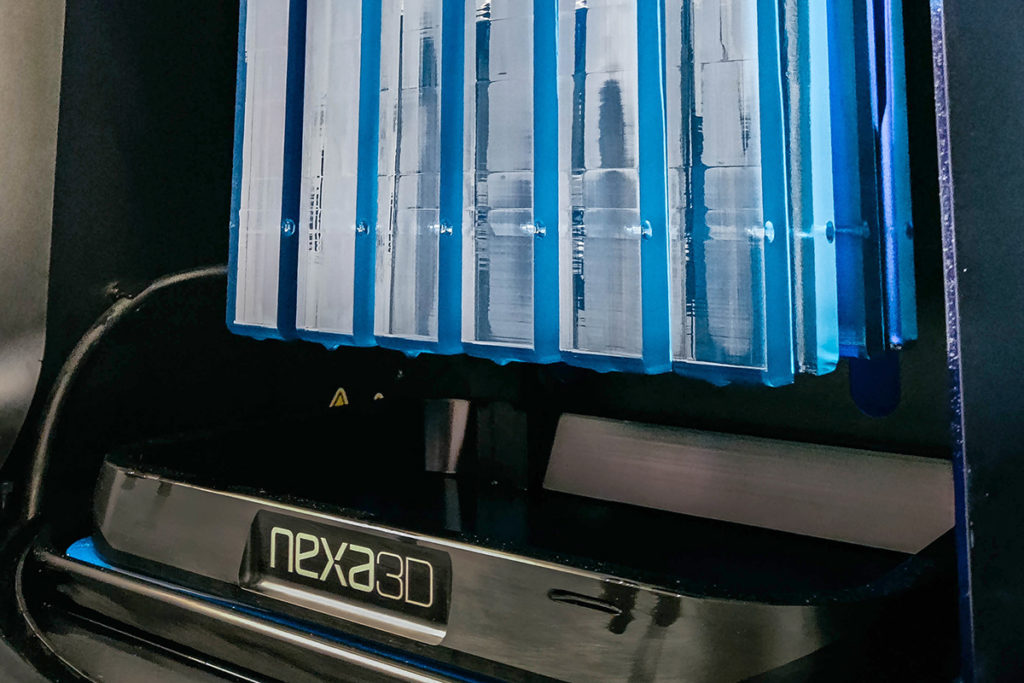

Desktop Resin 3D Printer

Offering industrial quality and speed at an affordable desktop price. The XiP resin 3D printer combines a compact footprint with a large build volume and fast print speed to deliver high-quality prototypes on your desktop. In addition to an open material platform, it has a broad range of validated rigid and elastomeric materials for all your prototyping and desktop manufacturing needs.

![]()

Fast Print Speed

The XiP desktop 3D printer is built on Lubricant Sublayer Photo-curing (LSPc) Technology, allowing users to print at blazing speeds of up to 18 cm per hour.

![]()

Open Material Platform

The XiP desktop 3D printer has a fully open material platform providing ultimate flexibility and access to resin 3D printing materials you need, when you need them.

![]()

Modular Design

XiP’s modular structure is designed for frequent use. Industrial-grade components provide optimized usability and serviceability.

3D Printing for Hollywood

When: June 30th, 1pm ET (10am PT)

What you will learn:

- How is 3D printing used in Hollywood

- How to decrease print time from days to hours (and learn how you can too!)

- How printing and finishing 70+ parts in a weekend is a big deal.

- How ultrafast industrial LSPc technology was brought to desktop 3D printers

Specifications

| Build Volume | 195 mm, Y: 115 mm, Z: 210 mm (7.7 in, Y: 4.5 in, Z: 8.3 in); 4.8 Liter Print Volume |

| Layer Thickness | 50 µm / 100 µm / 200 µm; 0.002 in/ 0.004 in / 0.008 in |

| Max Resolution | 4K Monochrome 9.3” LCD |

| Pixel Size | 52 µm |

| Hardware | Billet Aluminum Enclosure; 420 mm (16.5 inch) W x 350mm (14 inch ) D x 530 mm (21 inch) H; Rigid parallel linear rails, precision Ballscrew Z-axis; Ethernet / USB / Wi-Fi connectivity; 5.5 inch Color LCD Touchscreen Display |

| Build Materials | Henkel, BASF, and Keystone combined with special in-house resins |

“With XiP’s large build volume, fast print speed, and easier post processing, I’m able to iterate faster and validate new designs in hours versus days.”

– Paul Cilino, Mechanical Design Engineer and Owner at MotoCilino, LLC

Watch the XiP Resin 3D Printer At Work

Affordable Resin 3D Printer for Rapid Production

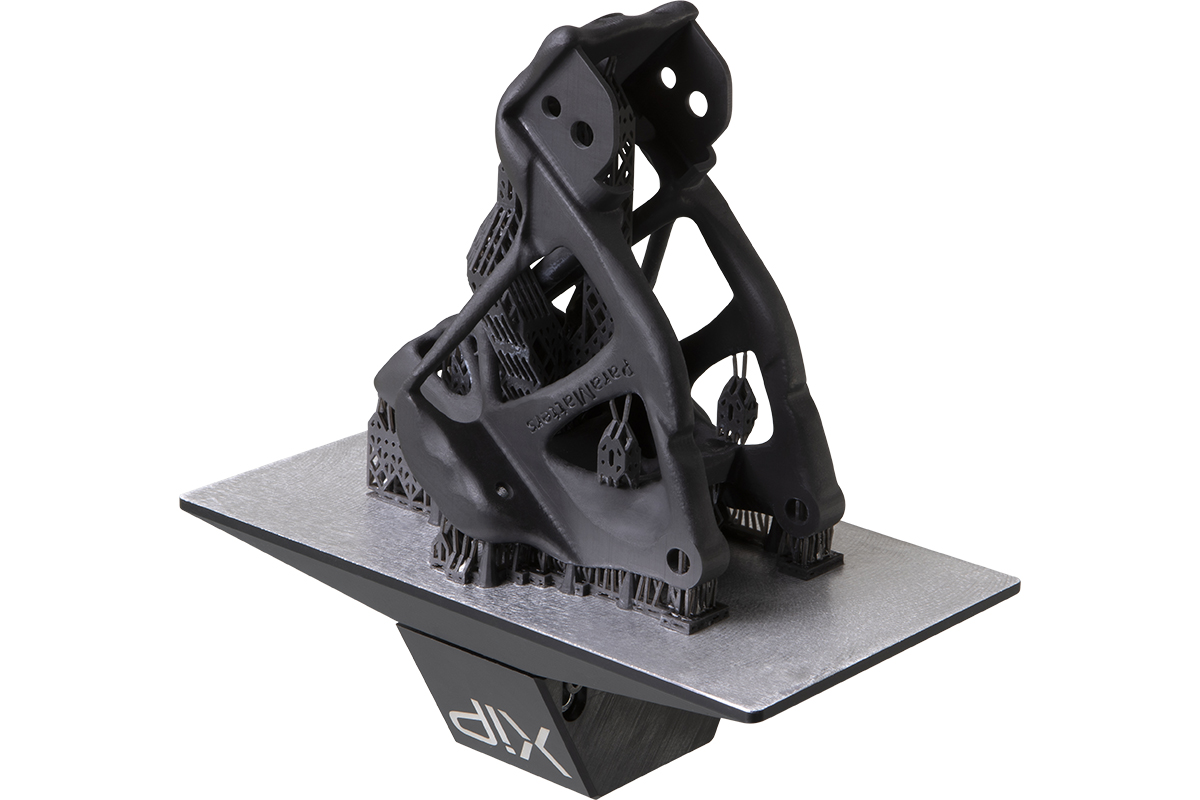

With its open material access, industrial performance, and modular design, the XiP is a best-in-class desktop resin 3D printer that offers the ultimate flexibility. Users can create consistent, high-quality parts and prototypes with reliability and repeatability using both Nexa3D validated resin as well as third party materials.

XiP Resin 3D Printer Reviews

XiP reviews highlight the impressive design and engineering behind this desktop resin 3D printer. Users appreciate its all-aluminum, recyclable body and sustainable packaging, which reflect a commitment to environmental responsibility. The modular design is frequently praised for allowing easy upgrades, making the XiP a smart, long-term investment for anyone serious about resin 3D printing.

Introducing xMOLD Resin

Combining design freedom of resin 3D printing with final production materials of injection molding with the acquisition of Addifab and its revolutionary Freeform Injection Molding process.

As Reviewed By

Nexa3D XiP — Fast, Easy and Cost Effective

Keypoint Intelligence

Nexa3D XiP – professional high-speed desktop 3D printing at a competitive price

3D Printing Industry

3rd-Party Engineering Report

Engineer’s Report – November 2022 by 3D Printing Industry Prepared by: Maël DUPORTAL

What’s in the Report?

- Packaging, Hardware, and Slicer Reaction

- Use of Printer

- Basic Printing Tests (Dimensional Accuracy, Repeatability, etc)

- Real Application Printing Tests (includes gearing, bike pedal, ULA rocket bracket, and generative design bottle holder)

- Post-Processing

- Conclusions

Download the Full 56 Page Report

EverCare Service Plan

Enhanced services and support designed to help you achieve the highest level of printing success on the XiP including dedicated teams, training, and printer hot-swap.

EverCare Plan

Download NexaX Basic

NexaX generates part-by-part fully customizable support structures, and has features to hollow parts and create internal lattice structures.

Download NexaX

Open Material Platform

Our growing network of the world’s leading material providers—including Henkel, BASF, and Keystone—unlock potential in a variety of applications for various industries.

Material Selector

XiP FAQs

The XiP desktop 3D printer offers precision driven by its 52 micron pixel size and layer height options of 50, 100, and 200 microns. For greater detail, users can customize the layer height down to 25 microns. Nexa3D’s anti-aliasing capabilities (down to 26 microns in the XY plane) and edge offset controls in NexaX software provide additional fine-tuning. According to an in-depth analysis by 3D Printing Industry, the XiP achieved a repeatability CP =1.89 for a tolerance of +/- 0.1.

Parts printed on the XiP with engineering-grade resins can exhibit tensile strengths up to 85 MPa and impact resistance values exceeding 50 J/m, depending on the resin. These characteristics make the printer ideal for functional prototypes, jigs, fixtures, and production parts. For optimal performance, follow Nexa3D’s post-processing guidelines and refer to the technical data sheet available on our website.

The XiP’s resin dispensing system is optimized for viscosities up to 3000 cps. Our process team ensures that the resin profile parameters are compatible with all resins offered, regardless of viscosity. For resins exceeding 3000 cps, such as xFLEX402, manual pouring into the vat is required.

The XiP’s LCD screen has a rated lifespan of 2,000+ hours, while the VAT, built with a billet aluminum frame, shows no significant wear during extended use. The VAT’s replaceable Everlast membrane minimizes wear, and with proper maintenance, can last up to 50,000 layers.

The XiP’s Lubricant Sublayer Photo-curing (LSPc) Technology allows it to achieve print speeds of up to 19 cm per hour. This speed is maintained without compromising layer accuracy, with fine resolutions down to 50 microns. The printer’s firmware automatically adjusts exposure times to ensure precision, even at high speeds. Fastest speeds at different layer heights: 12.6 cm/hr at 100 microns, 19 cm/hr at 200 microns.

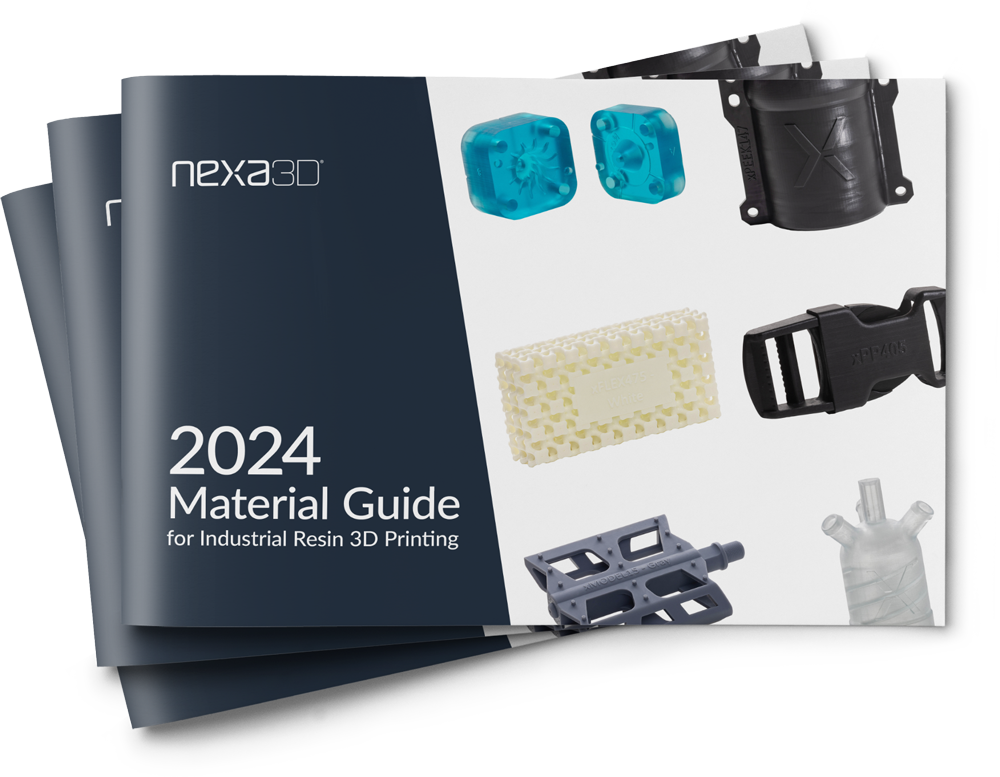

Download 2024 Resin Material Guide

Latest and greatest resin materials in 2024 featuring xPRO1100, xMOLD, xESD, FR, xDENT, and more.