- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

3D printing has made it easier for anyone to create, from professional designers to hobbyists. Filament-based 3D printers, in particular, are popular due to their affordability and user-friendliness, making them a top choice for many. These printers make it possible to turn digital designs into real objects using a wide range of thermoplastic materials.

The beauty of filament 3D printing lies in its ability to cater to a wide range of needs, ranging from amateur production of home items to professional manufacturing of groundbreaking innovations across various industries. Today, industrial-grade filament 3D printers are designed for high-volume production, offering advanced features, larger build volumes, higher resolutions, and a wider range of compatible materials with unique properties and finishes.

In this article, we provide information about the best filament 3D printers to bring detailed digital designs to life, their technological specifications, and their best-use scenarios.

What is a Filament 3D Printer?

A filament 3D printer is a type of 3D printer that uses a continuous thin plastic thread, known as filament, as the printing material for creating 3D structures. This filament, usually wound on a spool, is fed into the printer, heated, and extruded through a nozzle to create layers that build up the 3D-printed object.

Filament 3D printers are commonly used in fused filament fabrication (FFF) or fused deposition modeling (FDM) additive manufacturing processes where the thermoplastic filament is heated to a melting point temperature, extruded, and deposited layer by layer to form the final model. While traditional filament 3D printers have been widely used, a new generation of high-speed extrusion (HSE) 3D printers, such as the Essentium HSE series, are changing the industry. These filament 3D printers are designed to achieve high printing speeds while providing high part quality, making them ideal for rapid prototyping and swift mass production.

Filament 3D printers are popular because they can create 3D printing prototypes and functional end-use parts suitable for various applications across multiple industries. The versatility of filament materials available, ease of use, and relatively low cost compared to other 3D printing technologies make filament printers a popular choice for hobbyists, manufacturers, and designers alike.

What is 3D Printing Filament?

3D printing filaments are the thermoplastic materials used for feedstock by filament 3D printers. Thermoplastic materials are polymers that melt when heated and solidify when they are cooled.

These filaments are typically processed by being fed into a heating chamber in the printer’s extruder assembly, where the materials are heated to their melting point and then extruded (squirted) through a metal nozzle as the extruder assembly traces the path pre-programmed to create a 3D structure layer by layer.

One of the key advantages of filament 3D printers is their ability to use a wide range of thermoplastic materials, each offering different properties and capabilities to suit various applications. This makes them a flexible and accessible option for creating everything from toys to automotive parts.

Best Filament 3D Printers

Like other printers, filament 3D printers come in compact desktop sizes and much larger industrial sizes. Some of the best desktop and industrial filament 3D printers in the market today include:

1. Nexa3D HSE™ 280i HT

![]()

The Essentium HSE 280i HT by Nexa3D is the first-ever industrial 3D printer on the market that offers true independent dual extruders (IDEX). This large 3D printer is a cutting-edge technology designed to overhaul factory floor operations while outpacing other industrial 3D printers.

The HSE 280i HT 3D printer isn’t just any standard filament 3D printer. It is capable of processing high-temperature engineering materials at high rates of extrusion. It’s able to do this since it was designed to harness the power of 3D printing technology while increasing production efficiency by eliminating wasted movement using innovative linear servo motors. With a speed 15 times faster than the competition, the HSE 280i HT addresses longstanding strength, speed, and scalability challenges in 3D printing.

Nexa3D’s HSE 280i HT comes with two print heads and a Gen 5 Hozzle™ Heated Nozzle. With a massive build volume of 695 x 500 x 600 mm (or 595 x 500 x 600 in support and multi-process modes) and a print speed of 500 m/s, the HSE 280i HT is designed with versatility, reliability, accuracy, and unparalleled speed in mind.

The 3D printer also comes in five different print modes ranging from the Single Head Mode for printing individual parts at unparalleled speed to the Copy Mode that enables the simultaneous printing of two identical parts.

3D Printer Specifications:

- Authentic Independent Dual Extruders (IDEX)

- 695 x 500 x 600 mm build volume for large projects

- Print speed of 500 mm/s

- Nozzle temperature of up to 550 degrees celsius

- 5 different print modes (Single head mode, copy mode, multi-process mode, support mode, and a future feature called Independent Mode)

- Open material platform

Best for use in professional industries like electronic manufacturing, defense, and aerospace where speed, strength, scalability, and versatility are a priority during production.

Learn more about the Nexa3D HSE 280i

2. Nexa3D HSE™ 180

The Nexa3D HSE 180 series 3D printers consist of single-head extrusion printers designed to break down printing barriers related to speed, accuracy, scalability and versatility in manufacturing industries. These printers revolutionize the manufacturing landscape by operating at a remarkable and unmatched five to 15 times the speed of their competitors.

Featuring an X-Y stage equipped with linear servo motors that achieve printing speeds of up to 500 mm/sec and minimize wasted movement, the HSE 180 series is designed for unparalleled speed and maximum efficiency. With these servo motors, the printers achieve 1G acceleration and a rapid 1 m/sec movement speed.

The HSE 180 series has a robust build volume with a generously sized build plate that accommodates 85% of the world’s jigs and fixtures. The printers in the HSE 180 series are also equipped with an open ecosystem that is able to process materials from an extensive portfolio.

The Nexa3D HSE 180 series consists of HSE 180LT, HSE 180ST, and HSE 180 HT 3D printers, all with different functions and ideal applications in various industries.

HSE 180LT

The HSE 180LT is most suitable for printing low-temperature material in several key industries that include Biomedical Devices, Commercial Manufacturing, Footwear and Apparel, and Architecture and Design. Its key applications include:

- Prosthetic Sockets

- Orthotic Devices

- Low-Temp Jigs and Fixtures

- Rapid Prototyping

- Castings

HSE 180ST

The HSE 180ST is typically best used for printing standard materials in industries such as Automotive and Transportation, Consumer Goods, and Electronic Manufacturing Services. Its key applications include:

- Low-Temp Jigs and Fixtures

- Low-Pressure Mold Tooling

- NPI and Bridge-to-Production

- Manufacturing Aids

HSE 180HT

Lastly, the HSE 180HT 3D printer is used to print high-temperature materials. It is most suitable for use in industries like Aerospace and Defense, Semiconductor Device Manufacturing, and Oil and Gas for purposes such as:

- High-Pressure Mold Tooling

- High-Temp Jigs and Fixtures

- Connectors

- Functional Parts

All Essentium 180 3D printers by Nexa3D feature a single print mode known as Single Head Mode that allows for rapid printing of individual 3D-printed structures. They come with a massive build volume of 695 x 500 x 600 mm and an exceptional Hozzle™ nozzle with a sapphire tip that sets new benchmarks with temperatures soaring up to 550°C, thereby helping to achieve high-speed extrusion of high-performance materials.

Coupled with an open material platform that prints a wide range of materials, including Essentium specialty filaments.

3D Printer Specifications:

- 695mm x 500mm x 600mm build volume

- Open material platform with Hozzle™ heated nozzle

- 0.081 mm XY and 0.005 mm Z Motion System Accuracy

- X-Y stage equipped with linear servo motors

- Printing speed of up to 500 m/s and 1G acceleration

- Swift 1 m/s travel speed

Nexa3D HSE 180 3D Printers are best used in high-volume productions that require high throughput, swift printing speeds, and an ability to print a vast range of filaments across various industries. Are you interested in experiencing game-changing production?

Learn more about the HSE 180 3D Printers by Essentium.

3. Markforged X7

The Markforged X7 3D printer is an industrial carbon fiber 3D printer that uses the continuous fiber reinforcement (CFR) printing process to create flame-resistant, chemical-resistant, energy-absorbing, high-resolution draft parts from composite base filaments and continuous fibers. In many cases, the parts printed by a Markforged X7 are suitable for replacing machined aluminum.

The Markforged X7 industrial carbon fiber 3D printers offer micron-level laser scanning for closed-loop calibration, yielding parts with high repeatability and near-perfect surface finish. With a large build volume of 330 x 270 x 200 mm, the Markforged X7 is typically used in industries where printing large-sized parts with dimensional stability and stiffness is important.

3D Printer Specifications:

- Continuous Fiber Reinforcement (CFR) printing technology

- 330 mm x 270 mm x 200 mm build envelope

- 3D printing layer resolution between 50-250 microns

- Precision Ground Composite Bed

4. Raise3D Pro3 Plus 3D Printer

The Pro3 Plus 3D printer by Raise3D is a professional dual extruder 3D printer with a large build volume of 300x300x605mm, suitable for large-scale production and multi-sized rapid prototyping.

The 3D printer offers features such as a smart assistant system known as EVE, auto bed leveling, and an Air Flow Manager to improve heat dissipation and air circulation, creating a stable environment inside the print chamber. It’s also equipped with a HEPA air filter to maintain air quality during the printing process.

The Pro3 Plus comes with Raise3D’s 3D printing software ecosystem, that includes a 3D slicing program, ideaMaker, an open-software template called ideaMaker Library, and our cloud-based 3D printing software RaiseCloud. It prints a wide range of materials, including ABS, PLA, PETG, ASA, and PETG ESD.

3D Printer Specifications:

- 300x300x605mm build volume

- FFF Printing technology

- Dual-head with electronic lifting system

- Flexible Steel Plate with Buildtak

- Maximum build temperature of 120° C

- Heated bed made from silicone

- Mesh-leveling with Flatness Detection

- 1024 x 600 screen resolution

5. Original Prusa XL

The Original Prusa XL is a large-scale CoreXY 3D printer with a build volume of 36×36×36 cm (14.17”×14.17”×14.17”). It is equipped with a modular segmented heatbed with 16 individually controlled tiles designed to prevent heat deformation, which is usually present in printers with a single large heatbed. In addition, the printer is equipped with firmware featuring technologies such as Input Shaper, Pressure Advance, and Precise Stepping.

The XL is fully compatible with a wide range of various types of materials, including PLA, PETG, ASA, and PC.

3D Printer Specifications:

- 360×360×360 mm (14.17’’×14.17’’×14.17’’) build volume

- Tool Changer with up to 5 individual print heads

- Removable magnetic steel print surface

- Mesh Bed Levelling

- Power-loss recovery and power panic

- A dedicated CPU and advanced network features (WiFi and an Ethernet port)

6. UltiMaker Method XL

The UltiMaker Method XL is a large-scale 3D printer equipped with a built-in HEPA filter and activated carbon filter to protect air quality during processing and a patented variable environmental controlled temperature (VECT) to regulate heat within the printing environment.

It has a build volume of 305 x 305 x 320 mm and is powered by the UltiMaker Cura software. The Method XL prints a wide range of filaments, including high-performance filaments like ABS-R and ABS-CF.

3D Printer Specifications:

- 305 x 305 x 320 mm build volume

- ABS optimized dual extrusion

- Printing chamber heated up to 100°C

- Flexible heated build plate up to 105°C

- Integrated HEPA and activated carbon filters

- Open material printing with Labs extruder

- Remote CloudPrint Control

7. FLSun QQ-S

FLSun QQ-S has a 255 x 360 mm printing size and a magnetically attached print bed sensor. It also comes with a flexible three-axis linkage system, a 24V power supply, a lattice hot bed, and a touchscreen interface.

The FLSun QQ-S is equipped with a 32-Bit motherboard and a separate MOS module, allowing for stable prints even at high printing speed.

3D Printer Specifications:

- 255 x 360 mm printing size

- Heated bed with temperature of up to 100°C

- Printing speed between 30-150mm/s

- Auto leveling system and Resume Printing Function

- Silent operation with noise below 50 decibels

- Nozzle temperature of up to 270°C

- Full-color touchscreen interface

- Leveling sensor

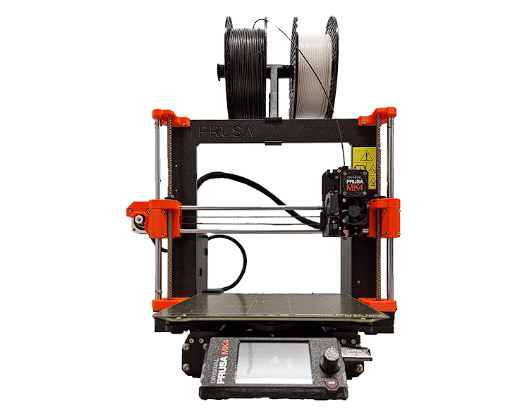

8. Prusa MK4

The Prusa MK4 is part of the Prusa 3D printer’s flagship series. It comes with a 32-bit xBuddy Mainboard, a Loadcell sensor, and Prusa’s patented Input Shaper and Pressure Advance technologies to decrease print time.

Besides the xBuddy Mainboard, the MK4 is also equipped with the next-gen (Nextruder) for remote printing, quick-swap nozzles, and an LCD screen with customizable UI that comes with features like one-click printing.

3D Printer Specifications:

- 250 x 210 220 mm (9.84 x 8.3 x 8.6 inches)

- Custom 32-bit xBuddy Mainboard

- Nextruder and Direct Drive extruders

- 3.5-inch graphic 65k Color LCD screen with simple UI

- Advanced sensors

- Magnetic heatbed with removable PEI spring steel sheets

- Fully supported by Prusa Connect for USB drive/LAN internet

9. Elegoo Neptune 4 Plus

The Neptune 4 Plus by Elegoo is a CNC machined aluminum extrusion structure with a large build volume of 320 x 320 x 385 mm. The 3D printer comes with a pre-installed Klipper motherboard and ARM 64-bit 1.5G main frequency quad-core processor that enables a printing speed of up to 500 mm/s.

The Elegoo Neptune 4 Plus features acceleration sensors to aid automatic calibration and improve print quality. It comes with a 300-degree Celsius high-temp nozzle kit, a 60W ceramic heating element, and a brass heating block with a platform capable of printing various high-temperature filaments such as ABS, PETG, and Nylon.

3D Printer Specifications:

- 320 x 320 x 385 mm print volume

- Default printing speed of 250mm/s

- Maximum printing speed of 500 mm/s

- Acceleration of up to 12000 mm/s

- High-temperature nozzle of up to 300 degrees celsius

10. Modix BIG-180X

Modix BIG-180X has a large build volume of 1800 x 600 x 600 mm. The Modix BIG-180X includes a dual print head, a 7-inch touchscreen, and 4 X-Z axis motors controlled individually to provide automatic bed tilt calibration. The printer also features an E3D Titan Aero extruder with an E3D Volcano hotend to manufacture 3D-printed structures from a wide range of filament materials including PLA, PETG, ABS, and TPU/TPE using FFF technology.

3D Printer Specifications:

- Print volume of 1800 x 600 x 600 mm

- Single Griffin extruder print head

- Layer thickness of 40-800 micron

- Fully enclosed print chamber

- Direct feeder system

- Heated print bed with PEI surface

- Maximum bed temperature of 120 degrees Celsius

- 7-inch touchscreen and LCD display

3D Printer Filament Types and Uses

There are several different types of 3D filaments, all with unique properties that determine their best-use cases and applications. These filaments can be widely grouped into 5 categories:

1. General Purpose

General-purpose 3D filaments are the most commonly used filaments that are adopted across various industries for non-specialty applications. They are typically easy to print with and offer a balance of mechanical and physical properties that make them suitable for a wide range of printing tasks.

These filaments are commonly used in prototyping, design, and production, and are often chosen for their ease of use, versatility, and affordability. Today, there are different types of standard filaments, with the most common ones like PA, ABS, PLA, and PETG leading the market today.

Filament Examples:

- PLA: Polylactic (PLA) is a thermoplastic monomer derived from renewable, organic sources such as corn starch or sugar cane. It is known for its ease of use, biodegradable properties, and relatively low melting temperature, making it ideal for an array of uses across various industries.

PLA is considered an environmentally friendly filament thanks to its ability to be recycled, incinerated, or disposed of by industrial composting. It’s available in a wide variety of colors to enable visually appealing 3D prints.

- ABS: Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic material with desirable mechanical properties commonly used for injection molding and 3D printing processes, especially those requiring detail and structural integrity. ABS is more difficult to print with than PLA but also offers properties such as extra toughness, high heat tolerance, good impact resistance, good abrasion resistance, superior melt flow, and strain resistance.

- ASA: Acrylic Styrene Acrylonitrile (ASA) is an amorphous all-purpose 3D printing filament with properties similar to ABS. It offers exceptional mechanical properties, superior aesthetics, and a UV-resistant feature. ASA is typically used in prototyping, 3D printed tooling, and low-volume production of highly customized parts through custom 3D printing. ASA can also be used outdoors and in applications requiring direct sunlight exposure.

- PETG: Polyethylene Terephthalate Glycol (PETG) is a filament known for its chemical resistance, durability, and excellent formability for manufacturing. It boasts high strength, good impact resistance, relative flexibility, and temperature resistance.

PETG is a great standard and general-purpose 3D printing filament due to its low fragility, low haze, and good printability, making it suitable for a variety of applications, including functional prototypes and production parts.

- TPU: Thermoplastic polyurethane (TPU) is a versatile flexible polymer that is resistant to abrasion, oils, greases and lubricants, and certain chemicals. Its properties make it suitable for uses requiring impact-absorption and a soft-touch surface. TPU has weather resistance, tear resistance, and low-temperature performance.

While its flexibility is one of its biggest advantages, TPU’s flexibility makes it more difficult to print accurately due to challenges such as dimensional precision and visible layer lines on the surface after printing.

- PP: Propylene (PP) is a semi-crystalline thermoplastic typically used in food packaging and consumer products. It has a high melting point of 130°C and can withstand millions of stress cycles without failing. PP is known for its chemical stability, making it resistant to many different chemicals, including acids and alkalis.

It is also flexible, lightweight, durable, and can resist impact loading without shattering, making it a great engineering plastic.

2. ESD-Safe

ESD-Safe 3D filaments prevent Electrostatic Discharge (ESD) events that may damage sensitive electronic components during the manufacturing process. These filaments are typically infused with carbon or graphite additives and are often combined with an optimized base material like ABS, PLA, or PC.

ESD-Safe filaments are designed to be used in applications that require electrostatic discharge protection in extremely sensitive electrical components. They offer consistent and reliable surface resistance, low particulate contamination, and minimal contribution to outgassing or ionic contamination.

These properties make them ideal for use in industries like the Semiconductor industry, industrial equipment manufacturing industry, and industries that create housings and casings for electrical appliances.

With ESD-Safe filaments, manufacturers can 3D print tools, covers, trays, and other prototypes or end-use structures ideal for preventing electrostatic discharge

Filament Examples:

- Essentium PCTG-Z : The Essentium PCTG-Z filament is an easy-to-print, non-marring ESD-safe material with an impressive impact strength compared to other filaments like the standard PETG. It boasts a high target surface resistance, excellent surface finish, and low hygroscopy that makes it unaffected by humidity. The Essentium PCTG-Z material prints in open air, is the perfect starting point for electronic jigs and fixtures, and is ideal in the creation of parts for explosion-proof environments.

- Essentium HTN-Z: The Essentium HTN-Z is designed for use in medium-duty electronics manufacturing in applications that require higher mechanical and thermal properties than standard nylons can offer. It is a very tough filament material with high wear/solvent/thermal resistance and best-in-class slow moisture absorption. The HTN-Z boasts a higher strength than PCTG, ABS, and Nylons. It is easy to print and doesn’t warp easily, making it ideal for printing electrical housing, Part trays for electronics manufacturing, and other ESD-safe fixtures.

3. Extreme Temperature

Extreme-temperature 3D filaments are specialized materials designed to withstand high temperatures without deforming, melting, or losing their physical and chemical properties. These filaments are typically used in industries where the printed parts are exposed to heat, such as aerospace, automotive, or electronic industries.

They offer enhanced thermal stability and resistance to heat, chemicals, and flame, making them suitable for use in environments where traditional PLA or ABS filaments are ineffective.

When it comes to recognizing extreme temperature filaments, certain standards like the filament’s heat deflection temperature (HDT), Vicat softening point, and glass transition temperature (Tg). HDT measures how well a material resists deformation under strain when at an elevated temperature.

Vicat softening points the temperature at which the stability of the filament begins to disintegrate. Lastly, Tg measures the temperature at which a solid material melts. Essentially, filaments with exceptional measurements of all three characteristics are often considered heat-resistant.

Filament Examples:

- Essentium HTN: Essentium HTN (High-Temperature Nylon) is a polyamide-based chemistry with improved mechanical and thermal properties compared to standard nylons. It has a high heat deflection temperature, improved chemical and solvent resistance, increased wear resistance, and better toughness than ABS and standard nylons. The Essentium HTN has best-in-class slow moisture absorption and high strength and is easy to print with thanks to its low-warp properties, making it great for printing electrical housings, insulating components, and jigs and fixtures.

- PEEK-CF: PEEK-Carbon fiber (PEEK-CF) is a very high-temperature resistant filament with a HDT of 280°C. It has good chemical resistance, toughness, stiffness, high creep resistance, high dimensional stability, and is inherently flame retardant.

4. Fiber-Reinforced

Fiber-reinforced 3D printing filament is a type of composite filament that contains reinforcing fibers mixed into the base polymer material. These filaments are made by combining a base material or polymer matrix (such as PLA, ABS, nylon, etc.) with reinforcing fibers like carbon fiber, glass fiber, or natural fibers.

The fibers are additives added to improve the mechanical properties of the base materials, contributing to increased strength, stiffness, dimensional stability, and impact resistance of 3D-printed structures. Hence, fiber-reinforced filaments combine the properties of the base polymer and the reinforcing properties of the fibers.

Fiber-reinforced filaments can either be categorized into glass or carbon fiber filaments, both with similar mechanical properties but distinct modes of creation, uses, and applications.

Glass fibers are made by melting silica to remove impurities, extruding the liquid through a heated metal plate with small holes in a method called a bushing, and stretching the glass strings into thin fibers after they are cooled using air and water. This creates a flexible, tough, and heat-resistant filament ideal for engineering prototypes and end-use parts that require optimal mechanical and heat resistance.

Carbon fibers are formed from a liquid polyacrylonitrile precursor by oxidizing a fibrous mix of carbon atoms at 300°C, carbonizing it in an oxygen-free oven at temperatures of up to 1,000 °C, and passing the carbon fiber strings through a surface treatment bath to etch the surface of the carbon.

This makes the carbon strings more resilient and better able to stick to coating chemicals. The process is followed by coating, chopping, and milling, after which the fibers are mixed with the base polymer(s) to create a composite material that can then be extruded into 3D printer filament.

Filament Examples:

- HTN-CF25: The Essentium HTN-CF25 high-temperature nylon is a polyamide-based chemistry with a 25% carbon fiber reinforced core. Considered one of the strongest ESD-safe filaments in Essentium’s catalog, this material offers high strength, impressive solvent resistance, and good temperature resistance. Although the HTN-CF25 is a very stiff filament, it is easy to process and print, making it a great replacement for light-duty aluminum parts. The Essentium HTN-CF25 is designed for tooling applications, for making jigs and fixtures, and creating high-strength end-use parts.

- Essentium PP-CF: Essentium PP-CF is a 20% carbon fiber reinforced polypropylene (PP) filament made with Luvocom® 3F resin from Lehvoss. It is a semicrystalline polymer commonly used in consumer goods and automotive parts when reinforced with a fiber filler. The Essentium PP-CF boasts excellent mechanical and chemical properties with limited warping.

It has a lower abrasion than glass-filled PP, excellent intrinsic mold release properties that reduces mold adhesion challenges, and a nonpolar nature that makes it ideal for low-temperature casting applications. The Essentium PP-CF is great in applications such as the production of glue and adhesive bonding clamps and automotive parts.

- Essentium PPS-CF: Essentium PPS-CF is a semicrystalline, high-performance polymer used in numerous challenging applications in various industries such as Aerospace, Oil and Gas, and Automotive. It is a 15% carbon fiber reinforced polyphenylene sulfide (PPS) filament with exceptional strength, stiffness, temperature, chemical, and wear resistance, as well as an outstanding price-to-performance ratio.

The PPS-CF filament is excellent for high-pressure and temperature tooling applications due to its high crystallinity and high deflection temperature of 240°C. In many cases, it is a suitable substitution for higher priced super polymers as PAEKs (PEEK, PEKK).

- Essentium PA-CF: Essentium PA-CF is a carbon fiber-infused polyamide filament specially formulated for additive manufacturing that requires easy-to-print filaments with exceptional strength. It is durable, flexible, has high impact resistance, can withstand temperatures upward of 150 degrees Celsius, and is optimized for low moisture absorption.

The Essentium PA-CF is readily printable with any open platform printer and can be used in applications such as handheld fixtures, automotive parts, and jigs and fixtures.

5. Biocompatible

Biocompatible filaments are those materials that can be used in 3D printing for applications requiring close contact with living tissue or the human body. These filaments are designed to be safe for use in medical devices, implants, and other healthcare applications, usually to print custom-made or mass-produced prosthetics with high accuracy and precise visualization. These filaments are suitable for over 30 days of skin contact and more than 24 hours of mucosal membrane contact.

Although many polymers, such as PLA, PEEK, and nylon are biocompatible by nature, not all of these 3D printing filaments are biocompatible. The 3D printed materials need to go through a certification process and, in some cases, to turn these base materials into certified biocompatible, they are combined with additives.

Filament Examples:

- Essentium PA-CF: Although originally a fiber-reinforced filament, Essentium PA-CF is also a biocompatible filament. In 2022, it passed the cytotoxicity, sensitization, and irritation requirements and is approved for safe skin contact.

- Essentium PET-CF: Essentium PET-CF is another fiber-reinforced filament that doubles as a biocompatible filament. It passes the tests for cytotoxicity, sensitization, and irritation requirements and has been approved to be used on the skin. The Essentium PET-CF material has been used for foot orthotics applications for patients.

- ABS Medical: Filament Spectrum Medical ABS is a high-quality material manufactured using ABS pellets that meet the biocompatibility requirements of USP Class VI, guaranteeing biocompatibility up to 30 days in topical contact with the human body. It features no base raw materials or toxic additives, ensuring that it is not only safe for medical use but also safe for food contact. The ABS Medical requires a nozzle temperature of between 235-255°C, bed temperature of 100°C, and a heated chamber for large prints.

- FibreTuff: FibreTuff is a bone-like 3D printing product with biocompatible ingredients often used in medical applications that call for bone replacement. It has a bone-like surface texture, as well as appearance and radio density with twice the strength as bioresorbable options like PCL. The FibreTuff can be printed with any efficient open platform printer with a 0.4-0.5mm nozzle size that prints at 235 – 240°C and a printer bed heated at 80 -100°C.

- ABS-M30i: ABS-M30i by Stratasys is a biocompatible 3D printing filament capable of sterilization and suitable for use in medical devices, pharmaceutical application, and food packaging . It complies with the test requirements of ISO 10993 (biological evaluation of medical devices), USP Class VI (plastic biocompatibility) and ISO 18562 (biocompatibility of breathing gas pathways in applications such as ventilators, breathing tubes, resuscitators and other airway-related devices). The ABS-M30i has a high tensile strength, toughness, and mechanical properties, making it a durable option for conceptual modeling, functional prototyping, manufacturing tools, and end-use parts.

- PC-ISO: PC-ISO is an industrial sterilizable biocompatible polycarbonate material used in professional medical, pharmaceutical, and food-packaging applications. It has a high deflection temperature of 133°C, high flexural strength, and good tensile strength. The PF-ISO filament is opaque, durable, dimensionally stable, and often used for applications requiring higher strength and sterilization.

Choose the Best 3D Printer for Filament 3D Printing

Filament 3D printers come in different specifications and sizes, each catering to unique needs and different budgets when it comes to 3D printing costs. Whether you are a hobbyist, designer, manufacturer, or 3D printing service, regardless of your level of experience with the art of filament 3D printing, the 3D printer market always has something to offer.

If you’re looking for cutting-edge technology and exceptional performance, the Nexa3D HSE 280i HT and HSE 180 Series 3D printers stand as top contenders in the provision of swift printing speed, unbeatable efficiency, high production quality, and the best surface finish. These printers are engineered for precision and accuracy, making them a creative workhorse for projects that require superior efficiency and quality.

Are you ready to experience unprecedented standards in filament 3D printing?

Learn more about the Nexa3D HSE 280i HT and HSE 180 Series 3D printers.