Fraunhofer Speeds Up Metal Injection Molding with 3D-Printed Tooling

Research institute adopts Freeform Injection Molding to provide rapid prototyping of complex metal parts

Fraunhofer IFAM

Fraunhofer IFAM – an institute in the renowned Fraunhofer Society – is a recognized leader in the field of Metal Injection Molding (MIM), and is serving companies in the aerospace, energy, maritime and other demanding industries. To support research into new applications while lowering lead-times and costs, Fraunhofer recently decided to implement the Freeform Injection Molding (FIM) process powered by Nexa3D’s XiP Desktop 3D printer and LSPc® technology. This platform enables manufacturers to quickly and cost-effectively prototype complex injection-molded parts before making investments in conventional metal tooling.

Challenge

Tooling for metal injection molding is costly and time-consuming to produce

In metal injection molding (MIM), metal powder is mixed with a plastic binder to create a feedstock that is then injected into a metal mold. The abrasive nature of the feedstock places high demand on the quality of the tooling, and the complexity of the MIM process typically results in the need for multiple iterations. Fraunhofer wanted to offer companies a path to quickly and cost-effectively test new concepts and turned to Nexa3D and Freeform Injection Molding to provide a solution.

“Freeform Injection Molding provides us with the perfect tools to support innovative companies as they test out new concepts and materials.”

– Sebastian Hein, Fraunhofer IFAM

Customer

Fraunhofer IFAM

Industry

Contract Research and Innovation

Products

- XiP Desktop 3D Printer

- Demolding Station

- xMOLD 3D printed tooling resin

Application

3D Printed Injection Mold Tooling

Advantages

- Ability to offer prototype metal parts in 10 days or less

- Significantly reduced prototype tooling costs

- Increased design freedom

- De-risked development, innovation

Solution

3D printed injection mold tooling using xMOLD resin and Freeform Injection Molding

Fraunhofer was inspired by other companies using Freeform Injection Molding and decided to introduce the XiP desktop 3D Printer and the xMOLD resin. This compact platform is the ideal solution for printing molds in the product size range typically encountered in MIM, and the xMOLD tooling resin has a strong track record for the molding of high-performance materials.

Benefit

2-week design cycle enabled for complex metal parts

By adopting the FIM process using Nexa3D’s XiP 3D printer and xMOLD material, the Fraunhofer IFAM team enables a host of benefits to their clients.

Rapid Prototyping: FIM enables Fraunhofer to quickly prototype MIM parts for customer demonstration and validation testing. The material properties of FIM parts have been shown to closely match those produced with conventional steel tools, ensuring accurate performance evaluation.

Time and Cost Savings: FIM allows Fraunhofer IFAM to dramatically reduce the time and cost required for pilot tooling production. The XiP printer’s exceptional speed allows for same-day printing and injecting while at the same time enabling cost and time savings exceeding 75% compared with conventional pilot tooling.

De-risking Development and Innovation: Fraunhofer IFAM has already demonstrated that FIM is compatible with the gold-standard Catamold feedstocks from BASF, enabling customers to use well-characterized materials for their development and innovation.

Customer Impact

Prototype MIM for complex designs demonstrated

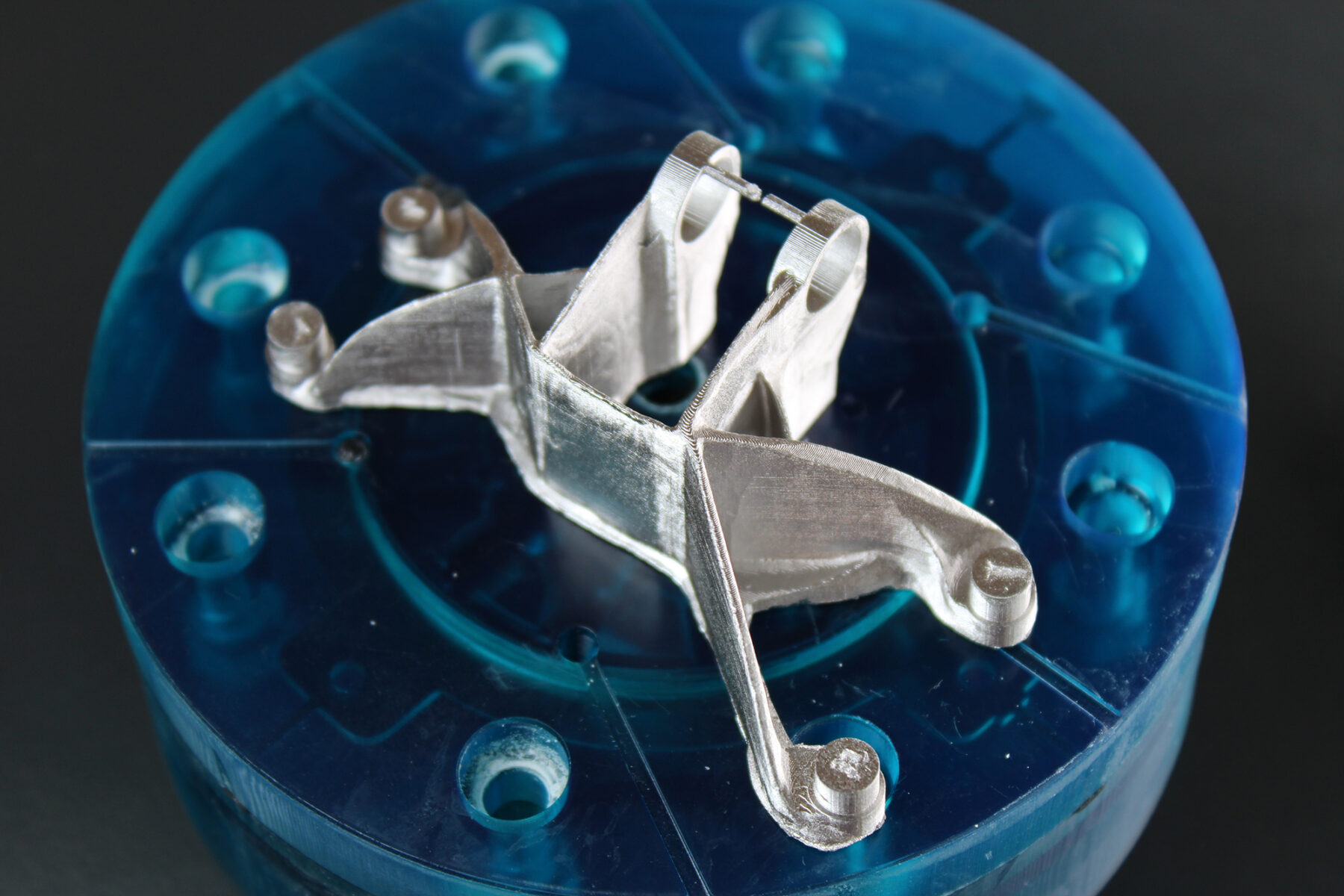

Metal injection molding has suffered from a scarcity of prototyping options. Conventional AM-based approaches, whether powder – or binder-based, cannot be used to evaluate flow paths, in-mold stress patterns or warpage of molded parts during debinding and sintering. As a consequence, injection molders have had to invest in high-cost pilot tools when wanting to validate part designs and process parameters. Already with the first project – modeled around the GE Jet Engine Bracket – Fraunhofer IFAM demonstrated the simplicity, speed and design freedom unlocked with Freeform Injection Molding.

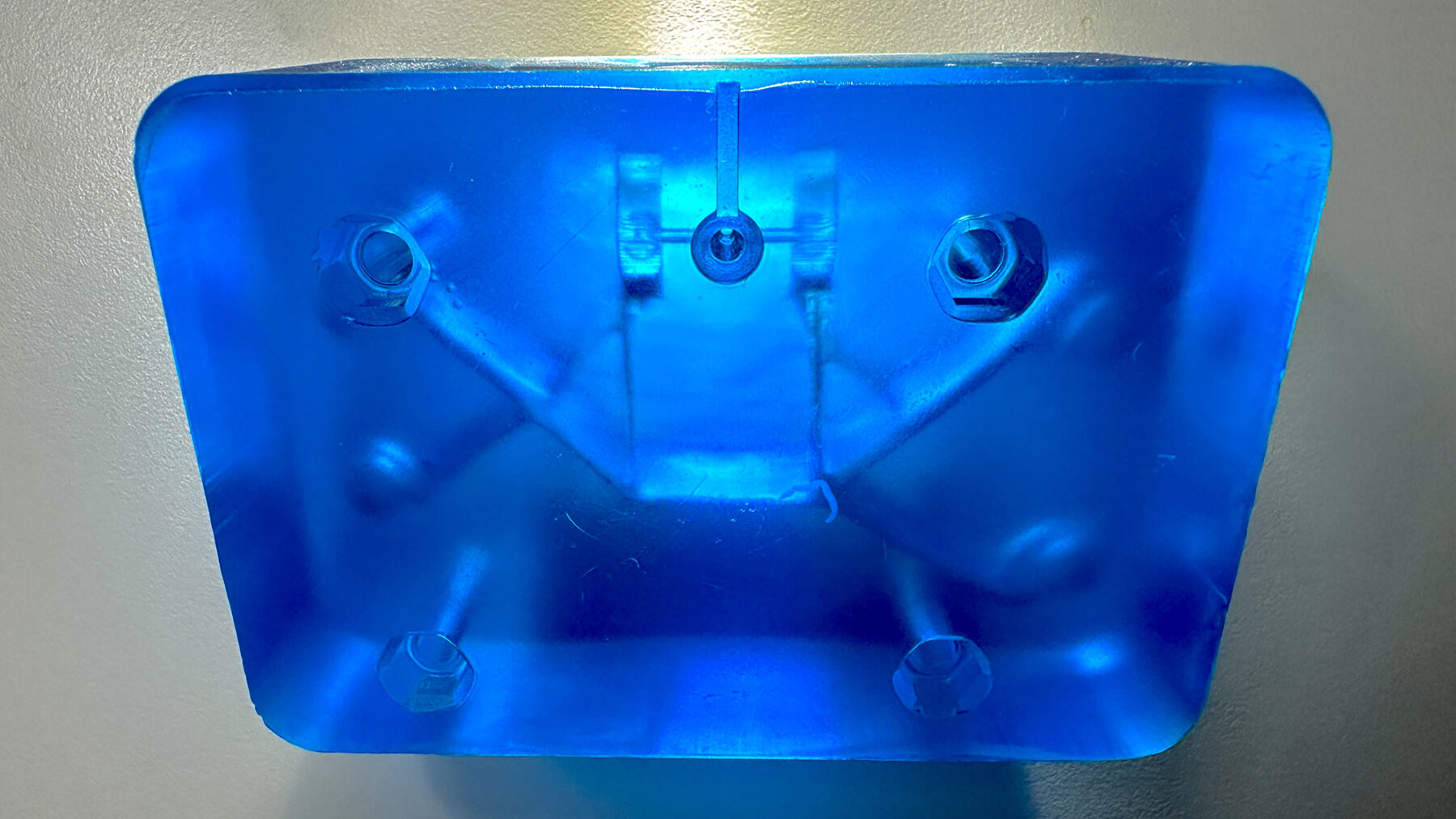

The Fraunhofer team decided on a bracket design that would be suited for injection molding, and to use a well-known off-the-shelf Catamold 17-4PH feedstock from BASF as the material. A XiP printer cell was used to print the soluble injection mold tooling, and an Arburg 320 injection molding machine was employed to complete the molding.

The project confirmed several important aspects of Freeform Injection Molding:

- Mold design time shrinks from days to hours, as molds do not have to incorporate split lines, ejector pins or sliding features.

- The manufacturing of test molds can be done in days instead of weeks.

- Injection Molding can be carried out using standard injection molding machines and feedstocks, and delivering a material quality that rivals that of conventional metal injection molding.

To learn more about Freeform Injection Molding, download the 3D Printed Tooling Design Guide or reach out for more information.

Download the Design Guide for 3D Printed Tooling

Comprehensive set of design guidelines for Freeform Injection Molding