Accelerating Automotive Aftermarket Production with Ultrafast 3D Printing

With over 25 years of experience as an automotive and aeronautical engineer, Patrick Gaspard knows a thing or two about how vehicles work. After years of industry work, he founded R3D – an engineering and 3D printing service provider. R3D does everything from prototyping to series production utilizing a fleet of industrial 3D printers. In 2020, Gaspard discovered that Nexa3D was making waves in high throughput additive manufacturing and quickly invested in an NXE 400 3D printer.

Challenge

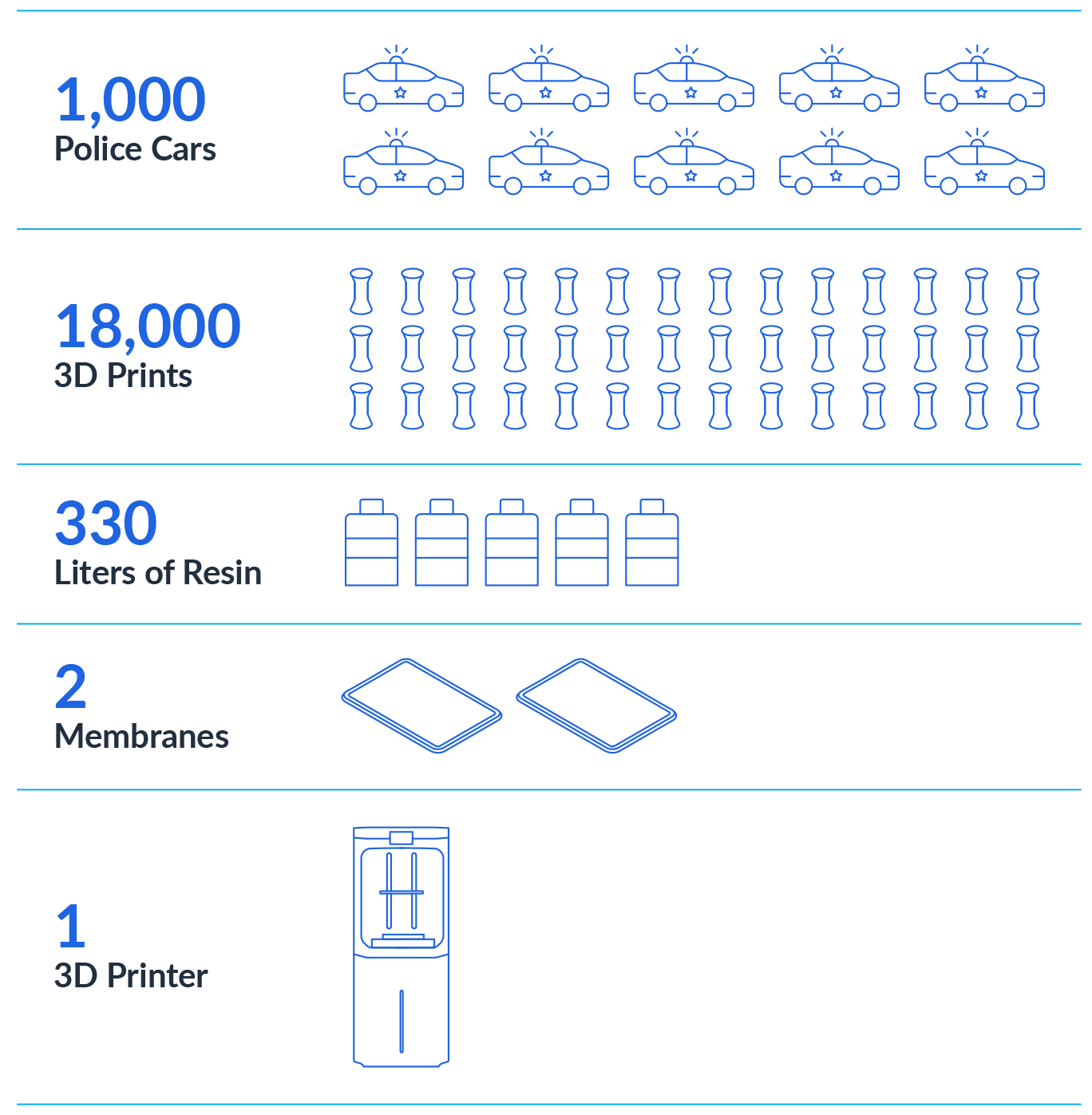

Toolless Production of over 7,000 Custom Aftermarket Components

In early 2021, automotive powerhouse Stellantis posted a bid for the design and manufacture of aftermarket components for 400 police cars for the French Gendarmerie. The request was to outfit the Peugeot 3008 Gendarmerie with nine individual brackets that would fixture various, expensive radio and computer components securely in place. The parts needed to be strong enough to secure the heavy electronics in both the driver compartment and in the trunk of the vehicle, even in extreme driving scenarios. They also needed to be durable and withstand UV radiation and hot and cold weather conditions in the vehicles.

On top of the required part performance, the vendor would have only three months to turn around 7200 components (18 individual components for each of the 400 vehicles). Not a lot of time when you consider these parts had to be custom designed from scratch.

“We only had a single NXE 400, but we were able to achieve the initial run of 7200 components well within the 3 month timeline. That’s a feat that would not be possible with any other 3D printer that I’ve used.”

Patrick Gaspard, Founder, R3D

Customer

R3D with Stellantis and the French Gendarmerie

Industry

Automotive

Products

- 1 – NXE 400 Industrial 3D Printer

- 330 Liters – xMODEL2505

- 2 – Everlast 2 Membranes

Application

Aftermarket Automotive Parts

Advantages

- Toolless prototype to production transition

- Part durability and strength (important for protecting expensive equipment)

- Repeatability and reliability for 24/7 production

- Quick turnaround to meet tight cusotmer timeline

Solution

Prototype to Medium-Volume Production—Fast

“With the NXE 400, I knew we had the tool for the job,” says Gaspard. Add in his automotive industry connections, he was easily able to make his pitch. He worked with the agency and the automotive OEM on the design, printing out some initial prototypes to match their specifications. They tested several resins but chose xMODEL 2505 from Nexa3D thanks not only to its ability to withstand some rigorous load bearing and durability tests, but also because of its light color which would make it more visible in the car trunk.

Once the tests were passed R3D was able to immediately begin production – thanks to the fact that the prototypes and the production both used the same 3D printing process, design, and materials.

“The ability to quickly go from prototype, straight into production without the need for machining an expensive tool was a major advantage with the relatively short turnaround time.” To run the jobs 24 hours a day, R3D reorganized shifts creating a night shift that could harvest the finished parts and launch the next print job.

“We only had a single NXE 400, but we were able to achieve the initial run of 7200 components well within the 3 month timeline,” exclaims Gaspard, “that’s a feat that would not be possible with any other 3D printer that I’ve used.” Reception was so positive, that two additional orders for 12,600 parts for 700 additional vehicles were placed and delivered. In one year, R3D used their single NXE 400 3D printer to manufacture 18,000 parts for 1,000 police cars. They used over 330 liters of resin during the process, but only two Everlast 2 Membranes (the main wear consumable of the NXE 400). With over one full year passing since the initial parts were received, the customer remains satisfied, and no additional replacement parts have been required.

Ready to bring high-speed 3D printing and on-demand production to your customers?