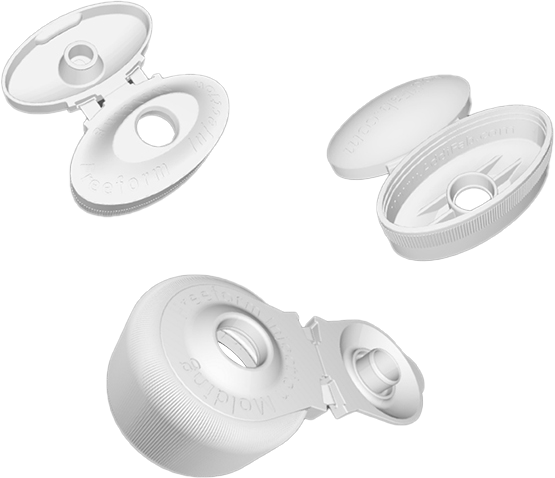

Part Design

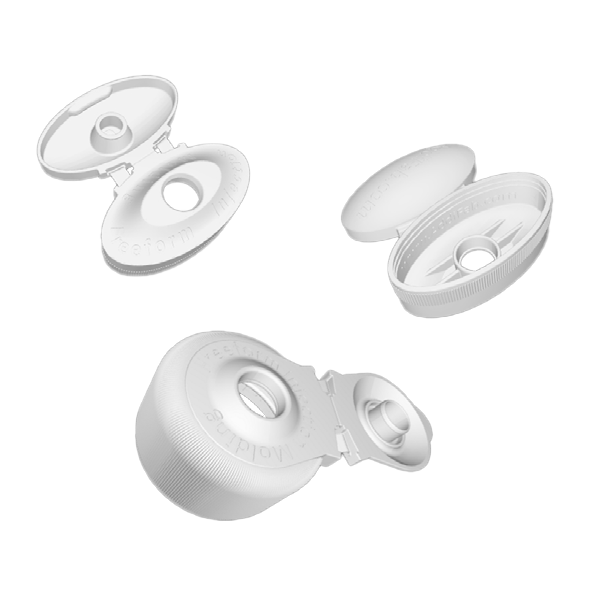

The flip cap often come in unique designs. The challenging aspect is often around the ‘living hinge’. STEP files are preferred.

The part is a classic flip cap in different designs. The materials used are both recycled polypropylene and food grade polypropylene.

The flip cap often come in unique designs. The challenging aspect is often around the ‘living hinge’. STEP files are preferred.

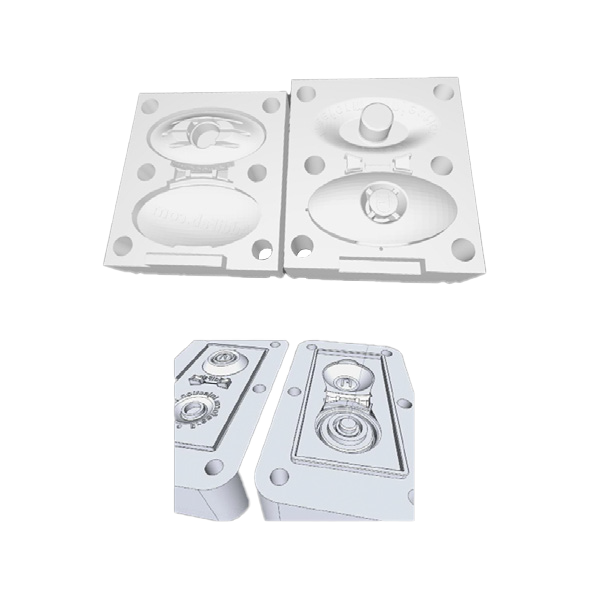

Next step is converting the STEP file into a mold design which is done by inverting the part into a cavity, in a block of material, and then adding the inlet gate(s) and initial venting.

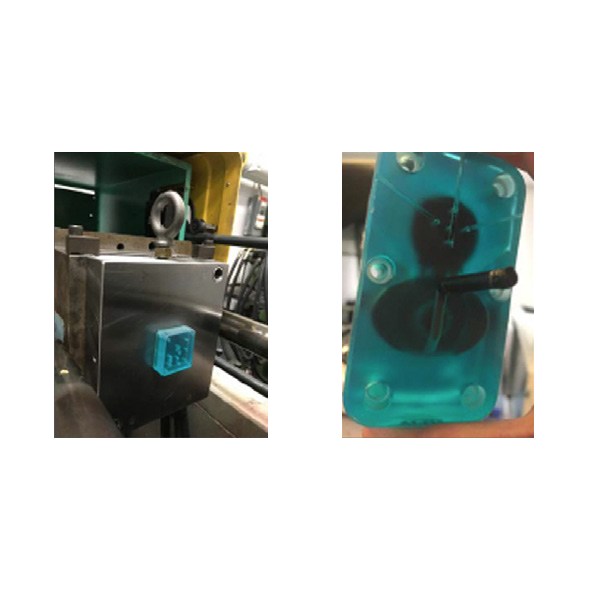

The 2-part initial design allows for quick visual Quality Assurance.

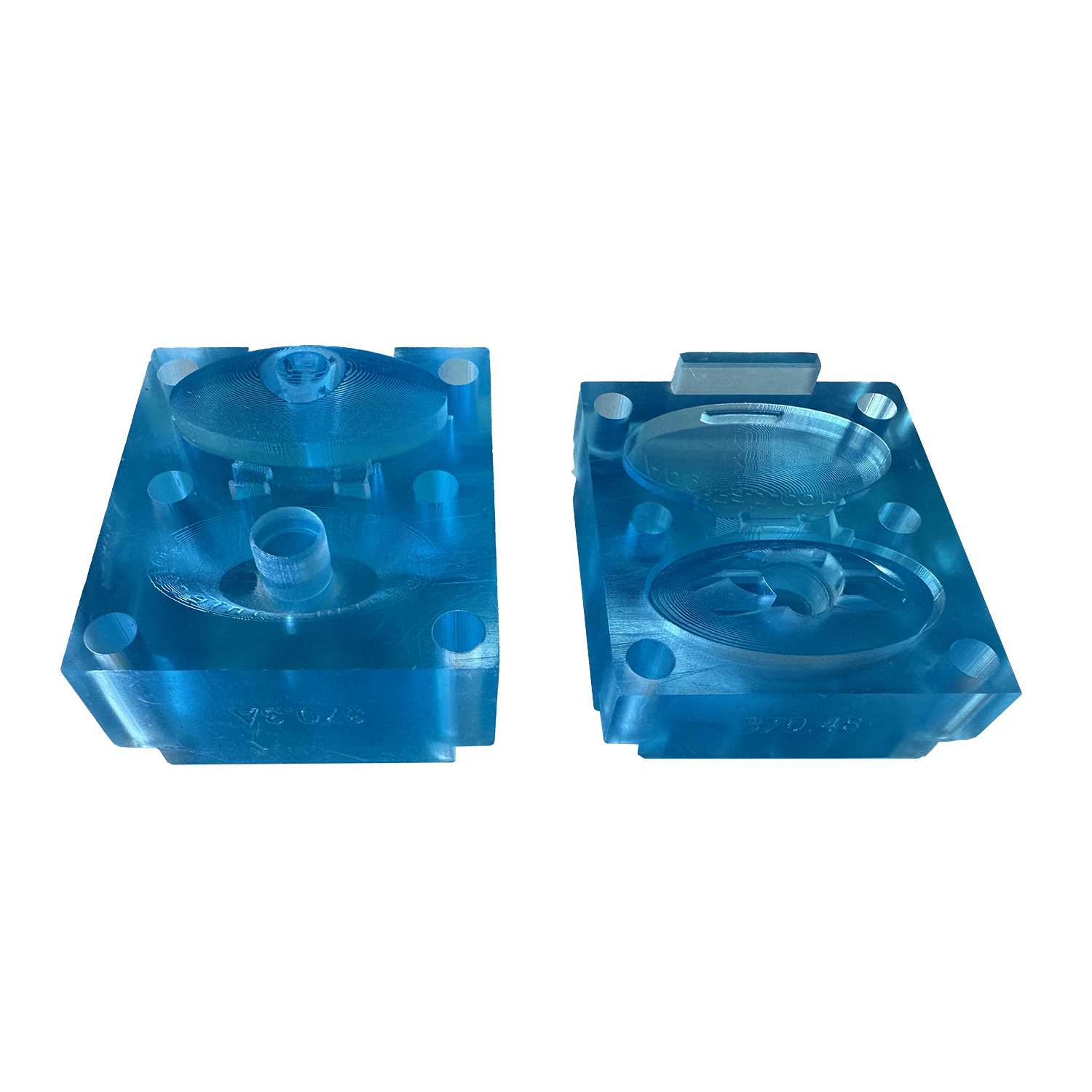

The molds were printed at a 100μm resolution to ensure good mold quality while optimizing the build for fast production.

The parts were molded on a 50-ton press. However, the molds work hand-in-hand with any installed base molding unit.

An aluminum mold frame waS used to hold the assembled mold, cycle time per part was around 5 minutes, and 1 minute cooling time after each shot.

The Nexa3D alkaline solution was used for demolding these parts, in just one day.

This time can be optimized through mold re-design or by removing a part of the mold before demolding.