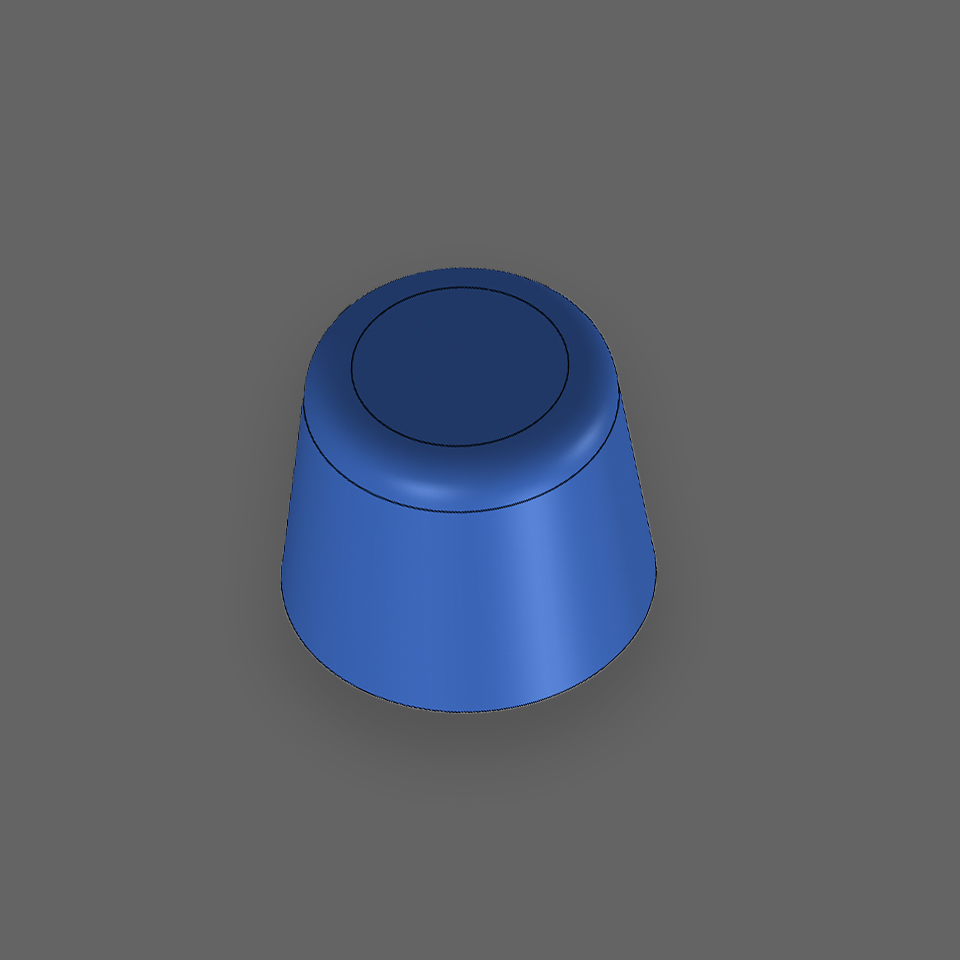

Part Design

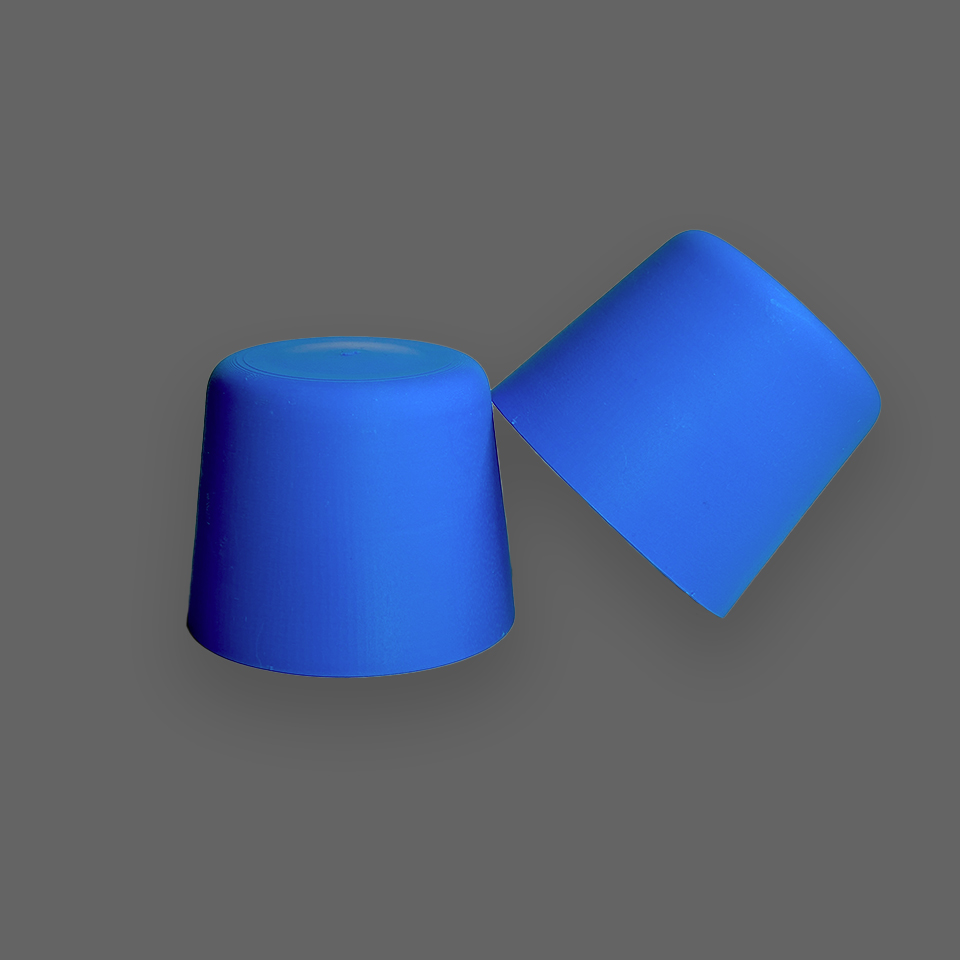

The bottle cap was made to resemble the early PepsiCo bottle caps and the challenge lies in the inner design to ensure proper fitment via molded threads.

Limited design freedom with the desired material.

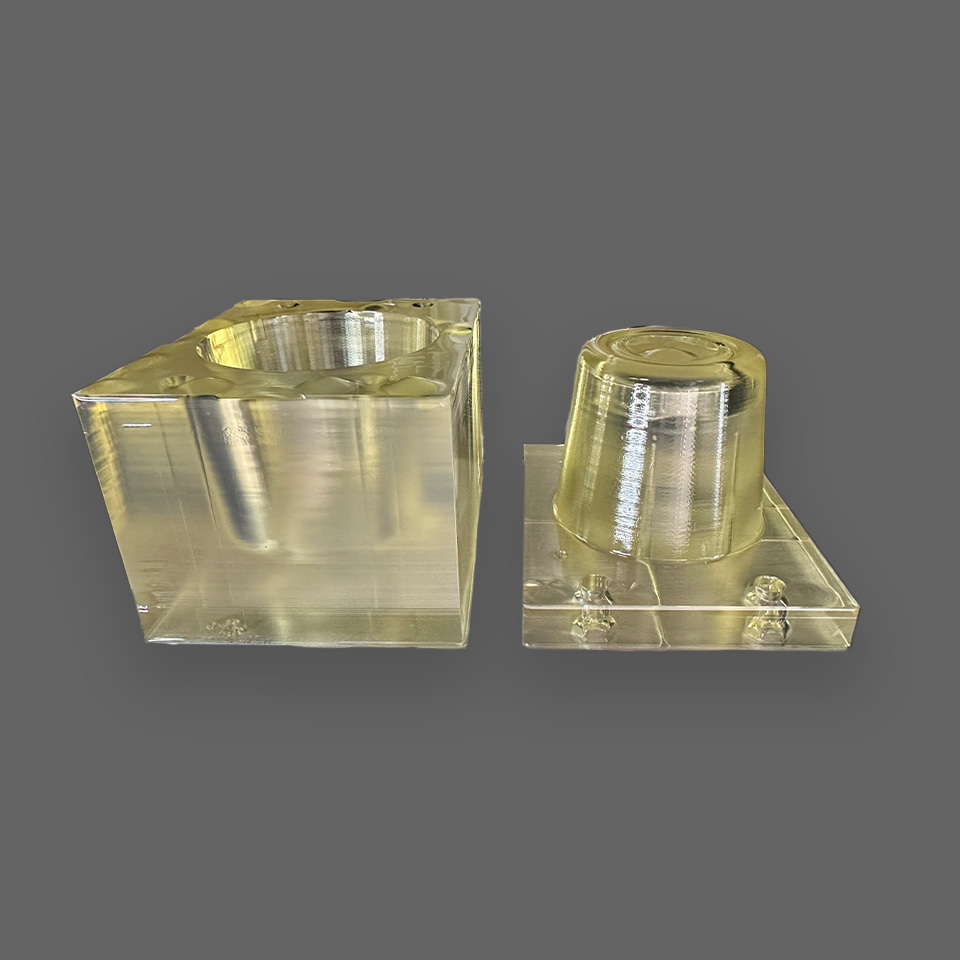

3D printed tooling with Freeform Injection Molding, enabling foodgrade materials.

The perfect bottle cap by PepsiCo. The material used for this project is PepsiCo blue HDPE.

The bottle cap was made to resemble the early PepsiCo bottle caps and the challenge lies in the inner design to ensure proper fitment via molded threads.

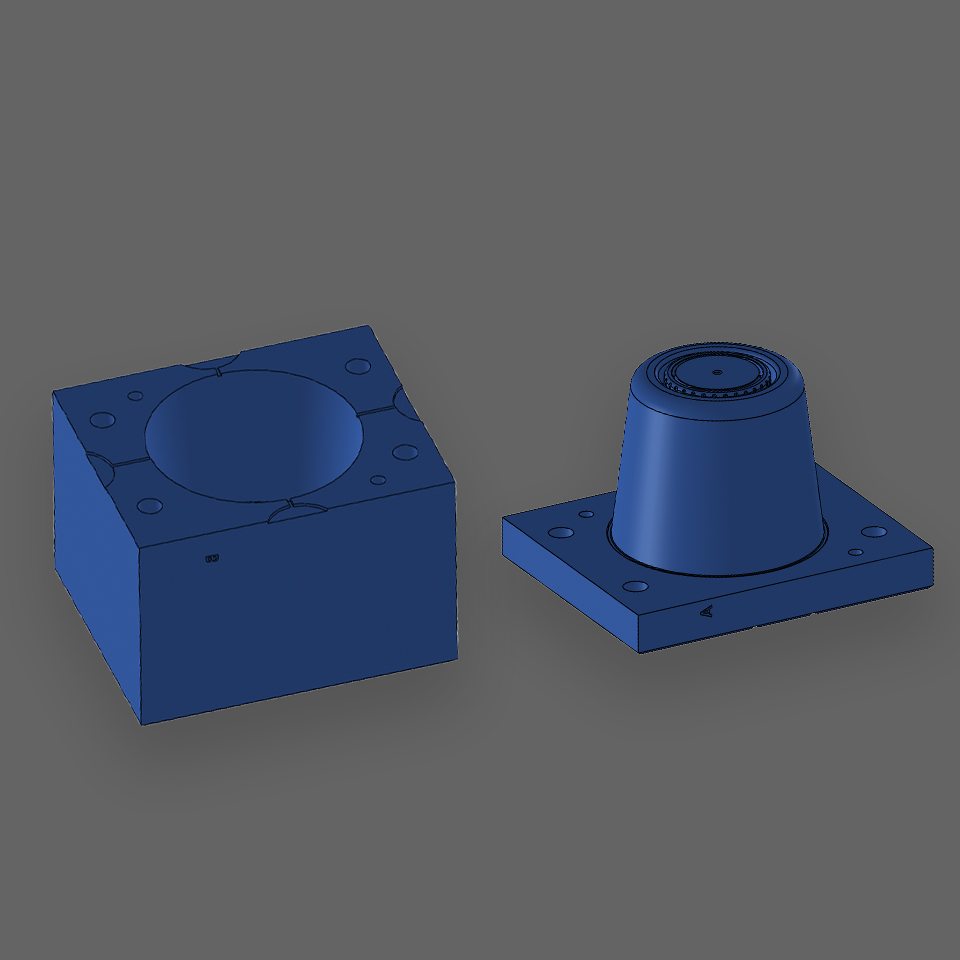

After the design is completed, the digital design (STEP file) in converted into a mold design which is done by inverting the part into a cavity, in a block of material, and then adding the inlet gate(s) and initial venting.

The 2-part initial design allows for quick visual Quality Assurance.

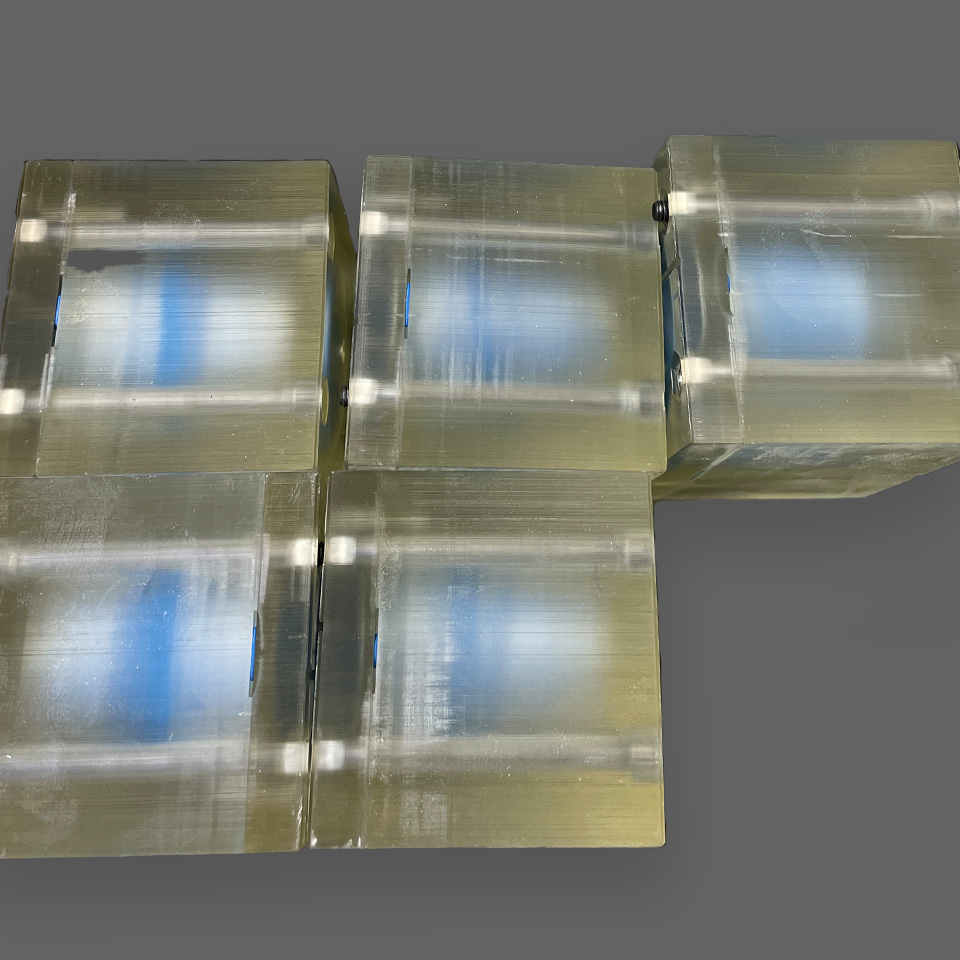

The molds were printed at a 100μm resolution to ensure good mold quality while optimizing the build for fast production.

The parts were molded on a 50-ton press. However, the molds work hand-in-hand with any installed base molding unit. An aluminum mold frame was used to hold the assembled mold, cycle time per part was around 5 minutes, and 1 minute cooling time after each shot.

The Nexa3D alkaline solution was used for demolding these parts, in just one day.

This time can be optimized through mold re-design, by removing a part of the mold before demolding, or direct removal of the part if possible.