Part Design

The handle was designed specifically for a Wilson Sporting Goods/DeMarini baseball bat. The challenges often surround the combination of strength, light-weighting and customized design.

Nexa3D Completes Acquisition of Essentium 🎉 Read the full story!

![]()

Slow production development of mold tool.

Increased product development by 88% with 3D printed tooling.

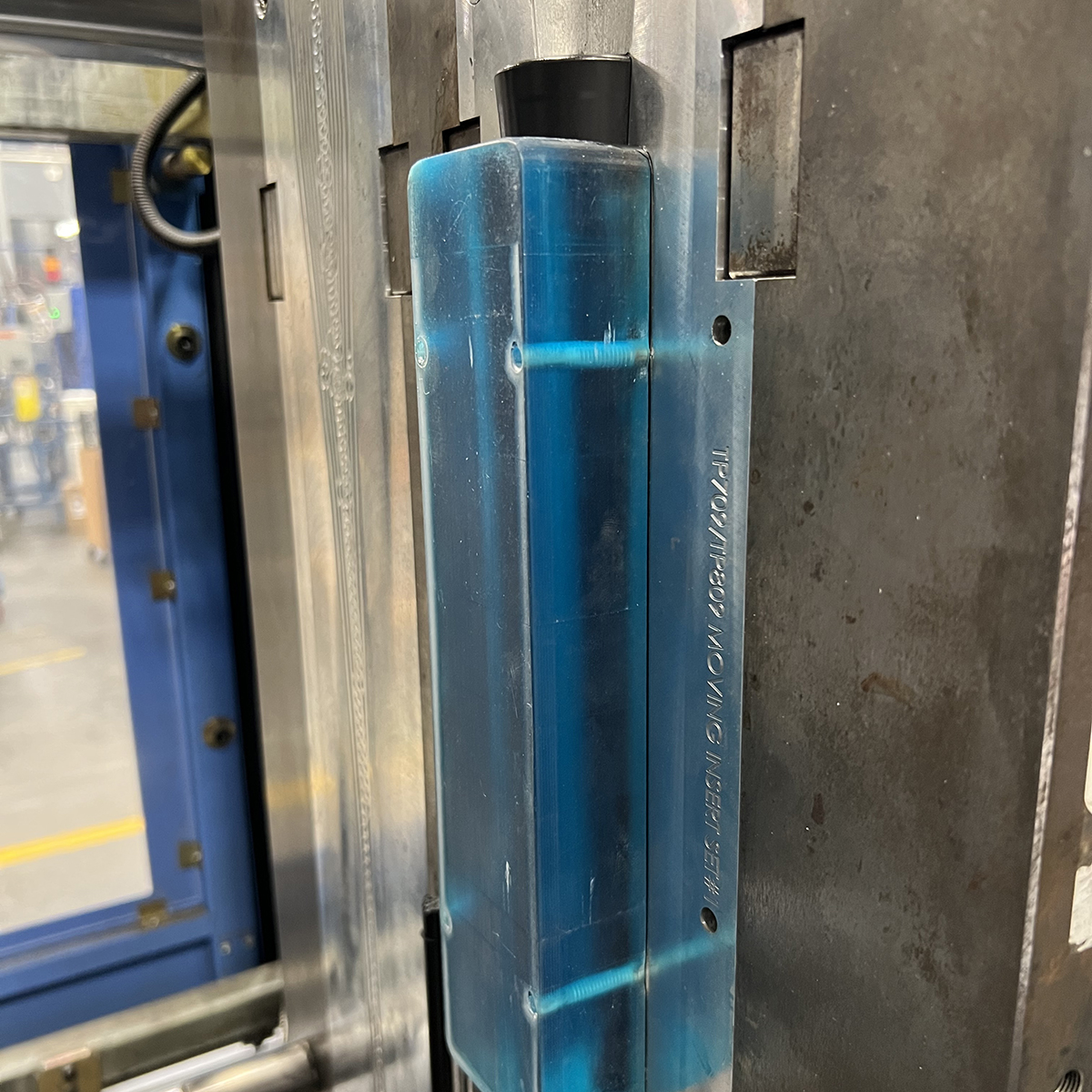

The part is a handle in a baseball bat. The material is a Wilson/DeMarini proprietary composite.

The handle was designed specifically for a Wilson Sporting Goods/DeMarini baseball bat. The challenges often surround the combination of strength, light-weighting and customized design.

After the design is completed, the digital design (STEP file) in converted into a mold design which is done by inverting the part into a cavity, in a block of material, and then adding the inlet gate(s) and initial venting.

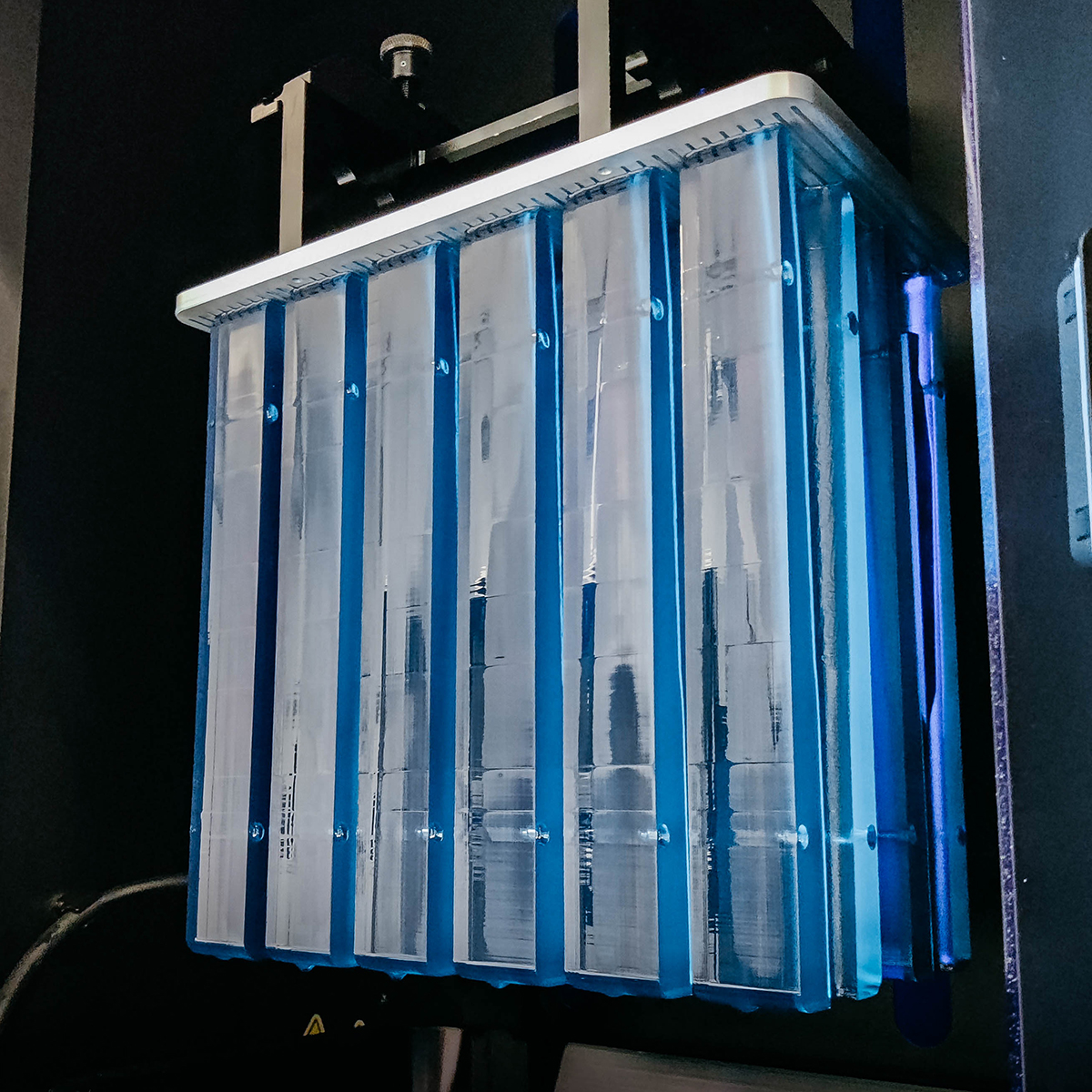

The 2-part initial design allows for quick visual Quality Assurance.

The molds were printed at a 76.5μm resolution to ensure good mold quality while optimizing the build for fast production.

The parts were molded on a 418-ton injection molding machine at Wilson Sporting Goods. However, the molds work hand-in-hand with any installed base molding unit. An aluminum mold frame was used to hold the assembled FIM mold, cycle time per part was around 5 minutes, and 1 minute cooling time was needed after each shot.

In this specific case the split mold allowed for manual demolding, meaning no part of the mold to had get dissolved, as the part could be pulled off.

Early hands-on testing for verification of assembly and performance using first-out-of-tool parts is valuable for most team members.