Nexa3D vs. Carbon M2 and M3

When it comes to industrial resin 3D printers that produce fast and repeatable results, the XiP Pro, NXE 400Pro and M2 / M3 / Max are some of the most commonly used printers. Here is a simple comparison between the three systems to help you determine the best industrial resin 3D printer for your particular application.

Nexa3D® XiP Pro

XiP Pro uses the latest generation LSPc® print technology. It is an open platform printer with the highest daily throughput in its class due to its large build volume and fast print speed. It is ideal for industrial users looking to scale additive production at the lowest possible cost of ownership, and without the annual lease expense.

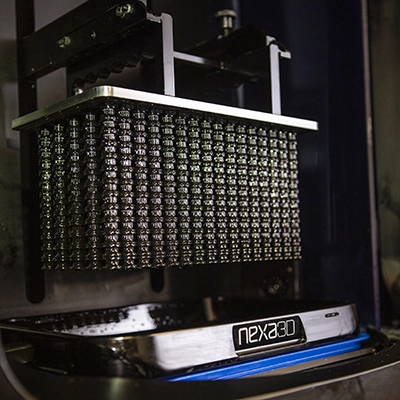

Nexa3D® NXE 400Pro

NXE 400Pro is the flagship LSPc® based printer offering large build volume, great accuracy, and fast printing. It is intended for industrial and dental applications requiring throughput and accuracy as well as lowest CAPEX investment.

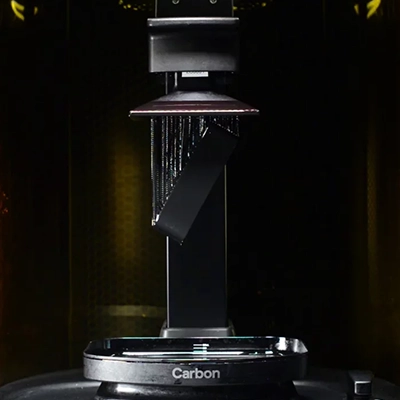

Carbon® M2 / M3 / M3 Max

The M2 & M3/Max are three of the most popular Carbon DLP printers. All are closed platform printers and available on annual lease-basis only.

Compare Specs

Scroll |

Nexa3D

|

Nexa3D

|

Carbon3D

|

|---|---|---|---|

Technology |

LSPc | LSPc | CLIP |

Light Engine |

LED/LCD (7K, 405nm) 46 μm with 23 μm sub-pixel resolution |

LED/LCD (7K, 405nm) 46 μm |

DLP (4K, 385nm) 75 μm |

Throughput |

|||

Build Volume |

292 x 163 x 410 mm (19.5 L) | 275 x 155 x 400 mm (17 L) | M2/M3: 189 x 118 x 326 mm (7.2 L) M3 Max: 307 x 163 x 326 mm (16.3 L) |

Min. Layer Height |

50 microns | 50 microns | 50 microns |

Materials |

Open with unlimited 3rd party resin options and 25+ verified engineering and dental resins* | Open with unlimited 3rd party resin options and 33 verified engineering and dental resins | Closed with 28 resins (14 dental, 14 engineering)† |

Material Vat Life |

1-2 years | 1-2 years | 24 hours† |

Post-Print Material Bake Time |

Not required^ | Not required^ | 8-12 hours† |

Preferred Geometries |

Latticed or Solid | Latticed or Solid | Latticed |

Software |

NexaX Pro | NexaX Pro | Design Engine |

*New resins and validation settings are expected to be added monthly to incorporate Nexa3D’s full resin portfolio.

†10 of 14 resins are two part resins that require manual mixing and have limited pot life.

^xPEEK is the unique NXE 400Pro resin that requires a post-print bake of ~3 hours.

Cost Comparison

Carbon M2, M3 and M3 Max are available exclusively on a 3-year lease basis which results in a minimum of $150,000 over that term (or $225,000 for the Max). By comparison, the XiP Pro industrial 3D printer is available for one-time purchase at $59,995, making it 60% less expensive than the smaller M2/M3 and 74% less than the similarly sized (albeit smaller build volume) M3 Max over the life of the hardware.

3D Printing Technologies

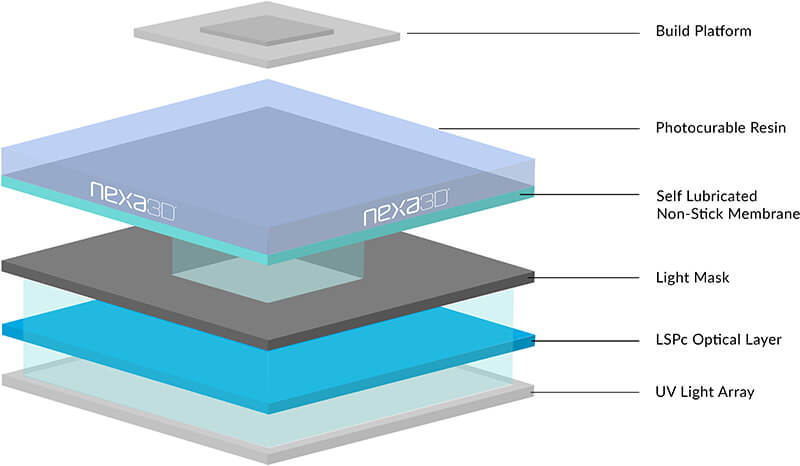

Nexa3D LSPc Technology

Lubricant Sublayer Photo-curing utilizes a proprietary membrane that reduces peel forces enabling high-speed 3D printing for parts small and large, solid and latticed. An industrial LED light engine further enables high resolution and high precision 3D printing.

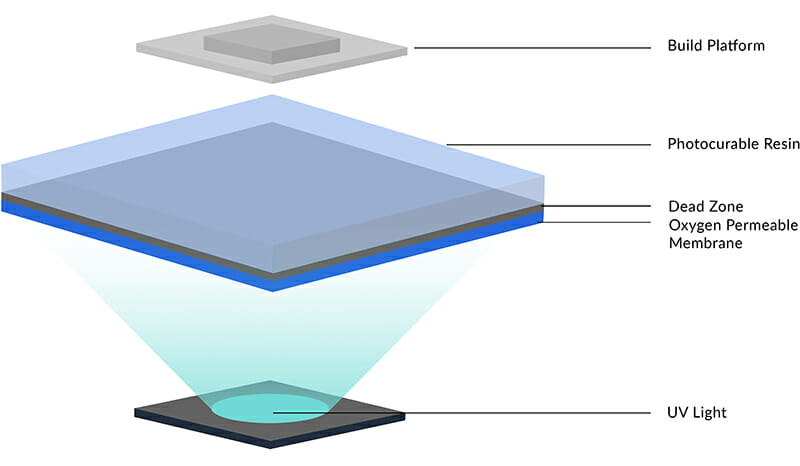

Carbon3D CLIP Technology

CLIP is a form of DLP 3D printing that utilizes on oxygen permeable membrane to create a ‘dead zone’ that prevents resin from attaching to the window. This enables high speed 3D printing but also is mostly limited to latticed parts due to the limits of oxygen permeability. The single projector chip can also cause warping at the edges due to the severe angle.

Materials Overview

Nexa3D

The XiP Pro and NXE 400Pro resins are available in a variety of high detail modeling and high performance engineering materials. They are single part photopolymers meaning they can sit in the vat for 1-2 years, and upon print completion only require basic washing and curing. All of Nexa3D’s printers are open platform, so if you cant find the solution with our 30+ resins, you can choose your own.

Carbon3D

The M2 and M3 series resins are available in high detail modeling and high performance engineering materials. They are mostly 2-part photopolymers meaning they will quickly expire once in the vat if unused after 24 hours. In addition to basic washing and curing, the 2-part resins also require an 8-12 hour baking cycle. The M2 and

M3 series do not have an open material platform.

NEW!

Download 2024 Resin Material Guide

Latest and greatest resin materials in 2024 featuring xMOLD, xESD, FR, xDENT, and more.