- Xometry Joins QLS 820 Manufacturing Partner Network - March 22, 2023

- Weerg Offers Quick-Turn Resin 3D Printing Service by Installing Four NXE 400Pro Printers - March 22, 2023

- Nexa3D Acquires XYZ Printing’s SLS Technology - March 19, 2023

Imagine the difference to global manufacturing if all businesses could consistently go from idea to finished part in a matter of hours. Gone would be the days of long design cycles and sitting waiting for 3D printers to finish—innovation and progress would be faster than ever. Here Avi Reichental, chairman and CEO of Nexa3D, explains how this could become a reality.

In the Industry 4.0 world, it’s not just survival of the fittest, but survival of the quickest. The businesses that can adapt first to changing market demands will come out on top, and this means investing in technology that helps bring high-quality products to market quickly. Traditionally, it has taken a long time to get a design idea right; the process involved many rounds of iteration, detailed analysis, optimization, and more. New software tools like generative design and topology optimization have sped up the design process immensely, using artificial intelligence to explore possible options and create designs that meet the constraints.

The design can also be optimized for 3D printing, such as by including lattice structures to reduce weight, material use, and cost, removing many manual processes and leaving the engineer with an easier decision to make. While next-generation software can help design engineers to complete their designs quickly, the process can still be held up by the speed of the 3D printer. Prints on traditional systems can take several days, making it impossible for many designs to be completed in a day.

This makes 3D printing in healthcare settings, or in manufacturing environments with a pressing need for a part, an unfeasible choice, despite the benefits it offers in design freedom. The speed of many 3D printers also limits the ability of service bureaus to deliver prints of their customers’ designs quickly, which may mean they lose out on business. The 3D printing speed barrier can even put designers off the technique as an option at all, leading them to turn back to injection molding for prototyping and end-part production.

Ultrafast 3D printing is opening additive manufacturing up as an option to more businesses, helping bringing products to market quicker and meaning 3D printing service bureaus can thrive.

– Avi Reichental, Chairman and CEO of Nexa3D

The need for speed

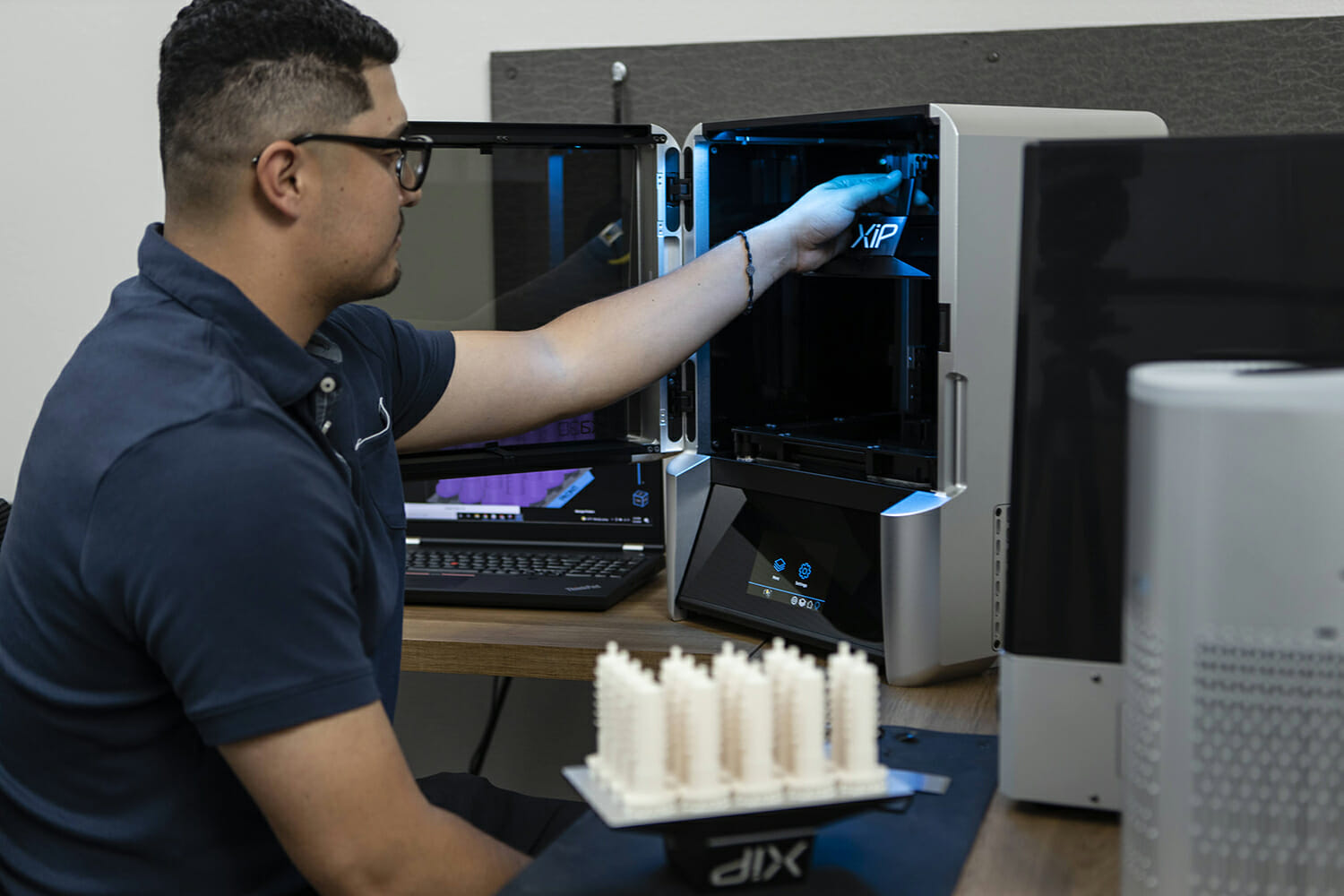

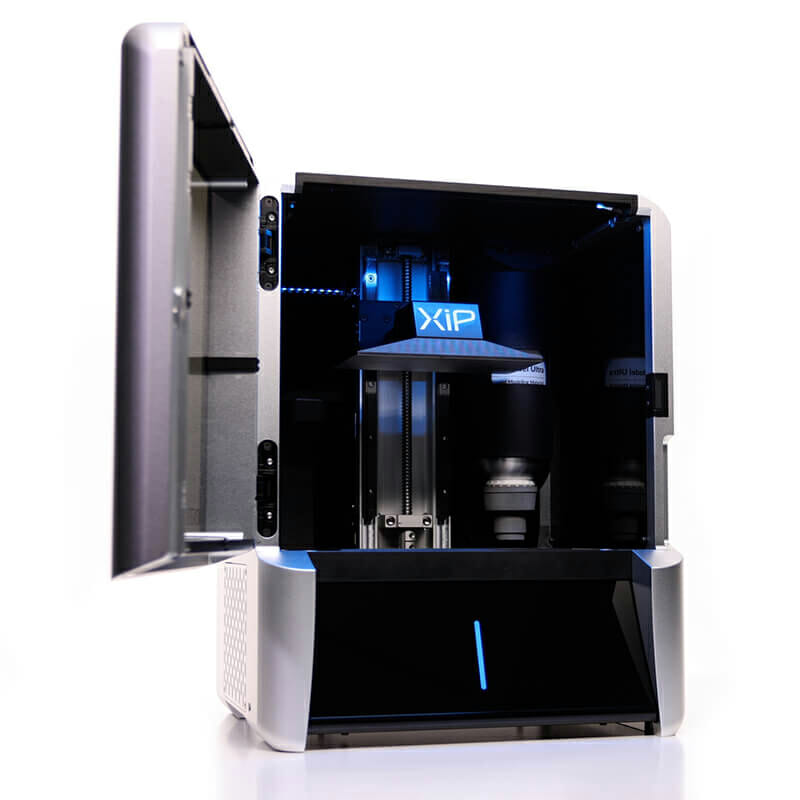

So, what is being done to break this speed barrier, and what are the impacts of faster 3D printers? Nexa3D has developed an ultrafast SLA 3D printer platform based on our proprietary lubricant sublayer photo-curing (LSPc) technology, combined with a patented structural light matrix capable of reaching a top speed of 1 cm per minute. Our systems can therefore drastically reduce the 3D printing cycles of precision functional parts from hours and days to minutes.

This technology is available both for industrial production lines and for the desktops of designers. With a 20x productivity advantage, businesses can service 20x more projects, designs, or patients. Ultimately, ultrafast 3D printing technology will become the foundation of many processes to reduce the challenges for manufacturers, service providers, and healthcare practitioners. For some businesses, it already is.

Real life examples

One great example of same-day part production comes from PAKT3D, a 3D printing service bureau in the UK, and its work with customer ARBR Bikes. Producing the bottom dow-tube guard bracket previously required an ULTEM mold tool that had a two-day lead time and was costly to produce. In just six hours, PAKT3D had 3D printed a newly designed mold tool, something that would have taken more than five days on an FFF 3D printer. Ultrafast 3D printing is opening additive manufacturing up as an option to more businesses, helping bringing products to market quicker and meaning 3D printing service bureaus can thrive.

Using ultrafast technology, it becomes realistic to envision a world where every manufacturer can come up with an idea, print a product, and hold it in their hand the same day, every service bureau can offer same-day delivery, and every healthcare patient can receive their 3D printed treatment option chair-side.