- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Custom 3D printing is the fusion of advanced 3D printing technology with individual creativity that allows for the production of objects tailored to specific design preferences and functional requirements. It’s about creating with purpose, precision, and personalization.

For businesses, designers, and even everyday enthusiasts, the benefits of custom 3D printing are manifold, including speedier prototype development, reduced costs, and the ability to provide users with customized products.

The applications span an impressive spectrum, touching realms like fashion, where custom-made jewelry pieces stand out, the automotive industry with 3D printed car parts, and the medical field, where tailor-made implants are revolutionizing patient care.

This article will dive into the world of custom 3D printing, exploring its intricacies, applications, and the transformative role it plays for professionals and hobbyists alike. Whether you’re an industry veteran or simply curious, this guide promises insights into a technology shaping our future.

What is Custom 3D Printing?

Custom 3D printing is the process of creating objects using 3D printing technology based on specific, individualized designs or specifications. This can encompass anything from bespoke machine parts or prototypes to 3D printed orthotics.

The process typically begins with a digital 3D model, designed to the client’s specifications, which is then printed layer by layer using the chosen material, resulting in a one-of-a-kind object.

How Custom 3D Printing Works

Custom 3D printing involves employing a 3D printing service to create personalized objects specifically tailored to meet your needs using several manufacturing steps.

These steps include:

1. Procure Your CAD File

A custom 3D printing process begins with the Computer-Aided-Design (CAD) model of the object you want to create. A CAD file is usually created with CAD software and houses information about a 3D model, including information like geometric data, manufacturing data, material properties, and other necessary production information. This file serves as the blueprint or architectural plan for the subsequent 3D printing manufacturing process.

During custom 3D printing, you can either generate the CAD file or get the 3D printing service to create one that fits your specifications. If you choose to get a custom 3D printing service or professional to create your CAD file, simply:

- Define your project requirements and discuss your design ideas

- Provide measurements, material preferences, technical requirements, and other necessary information

- Review the design and provide feedback if necessary

- Approve the design and request your CAD file

2. Choose a Custom 3D Printer

Nexa3D’s resin 3D printers

Once your CAD file is ready, you need to choose the right 3D printer for the printing process. The type of 3D printer you choose will determine the quality of your custom products, size, printing duration, and 3D printing costs.

There are various types of 3D printers, ranging from resin 3D printers to SLS 3D printers, each with its unique capabilities, choice of material, print or build size limit, and printing techniques.

3. Build Your Order With Required Specifications

With your CAD file ready and your preferred printer chosen, the next step involves building your order by specifying the various parameters that determine the outcome of your custom order. This includes deciding factors such as layer height, size of the print, 3D printing materials, printing speed, infill density, and placement of the print.

The specifications chosen determine your product’s final print and quality. If you can’t decide what the best specifications are, your 3D printing service will offer guidance to fine-tune your product specifications for the best results.

4. Approve the Quote

After determining your product specifications, you can work with a 3D printing service provider to manufacture the part if you don’t own a printer. They will send you a quote containing all information about your custom 3D printing order while also detailing production cost and estimated production-delivery time.

It’s important to review the quote to ensure it’s accurate and aligns with your budget and production timeline. If all information checks out, you can approve the quote so your 3D printing service provider can get on with the production of your custom order.

5. Receive Your 3D Printed Product

Gentle Giant Studio x Nexa3D custom character models

After you approve the quote and the 3D printing process is complete, you will receive your 3D printed product. The delivery time depends on the manufacturing workflow, level of customization, design complexity, and size of the object.

Delivery time can range anywhere from a few hours to several days.

Custom 3D Printing Services

Custom 3D printing offers a suite of services that cater to the needs of these industries. Some of these services include:

Rapid Prototyping

Rapid prototyping is the swift and cost-effective fabrication of a physical model or part that can be used to evaluate an end-use product’s functionality. These 3D printed prototypes are created to enable manufacturers and engineers to test out various versions of a product while reducing development time and costs.

This enables a refinement of your design ideas, ensuring design validation before you commit to mass production.

Concept Models

Concept models are used as valuable communication tools for visualizing and communicating design ideas. Custom 3D printing services are ideal for creating concept models that provide a tangible representation of ideas to be explored. For example, an architect might 3D print and assemble a small yet extremely detailed version of an estate building project.

This concept model would represent the ‘bigger picture’ of future larger models during meetings with clients and investors. They make it possible to bring new ideas to life and enjoy the freedom to reiterate designs as needed.

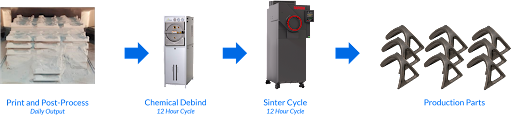

Production Parts

Custom 3D printing is especially beneficial for industries that require on-demand and highly customized products, such as prosthetics in healthcare, dentures in dentistry, or customized car parts in the automotive industry.

With custom 3D printing services, industries can enjoy low-volume, on-demand, and cost-effective production.

Professional Design

Custom 3D printing service providers often provide professional expertise in addition to printing services. As such, if you lack the professional experience to bring your idea to life and create a 3D model, the service provider can work with you to design and optimize your idea concept.

Custom 3D Printing Technologies

There are different 3D printing technologies used for custom 3D printing services. Each of these technologies determines the printing method, material, duration, and other specifics that go into creating the three-dimensional structure.

Selective Laser Sintering

Selective laser sintering (SLS) is a powder-based technology that creates complex geometries and components from engineering-grade materials like polymers and metals. These printers use high-powered lasers to fuse small particles of various materials like plastic powders into a solid object in a process known as sintering.

SLS works by heating a bed of powder material with the laser to selectively melt parts of the powder. Once melted, the powder solidifies and forms a layer of the desired part shape. A new layer of powder is added above this melted layer and subsequently melted and fused to the layer below. This process is repeated until the entire part has been constructed.

SLS is widely used in automotive, aerospace, and medical industries to produce parts that require tight tolerances or intricate details such as dental aligners, hearing aids, orthotics, and prosthetics.

Resin 3D Printing

Resin 3D printing, also known as vat polymerization, is a 3D printing process that uses liquid resins to create three-dimensional objects. It uses a short wavelength light source to selectively cure or solidify the resin layer by layer.

Resin 3D printing produces highly detailed and smooth objects with intricate features. As a result, it’s particularly suitable for applications requiring fine details and precision, such as in the fields of jewelry design, dental work, and creating highly detailed prototypes.

Metal 3D Printing

Metal 3D printers create three-dimensional objects by fusing metal powder layer by layer using a high-powered laser or electron beam. It often uses stainless steel, aluminum, and titanium materials for creating prototypes and end-use parts.

Cold Metal Fusion is a patented process developed by headmade materials®. It is a method that combines the advantages of fast cycle sintering with established powder metallurgy processes to produce titanium and steel parts.

Cold Metal Fusion is a new and unique process only done by a few SLS printers in the market today. Using a polymer-coated metal powder, Nexa3D’s QLS230 and QLS236 produce “green” parts in a low-temperature processing environment. Parts then go through a secondary debinding and sintering process that burns out any remaining polymer and sinters metal particles together to form final metal components.

Learn more about the QLS230 and QLS236.

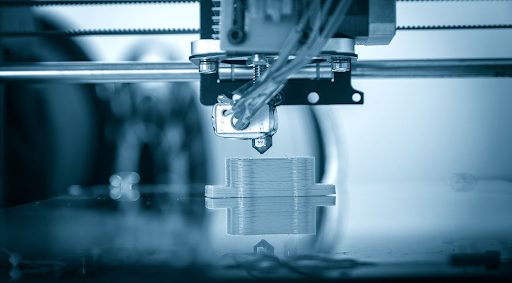

Fused Deposition Modeling

Fused deposition modeling, or fused filament fabrication, uses a heated nozzle to make and deposit melted thermoplastic filament layer by layer until the design is fully created. The plastic or thermoplastic filament is fed through a heated nozzle, where it’s melted and then deposited onto the build platform.

Once the first layer has cooled, the next layer is deposited. This continues until every layer is complete and the structure is fully formed.

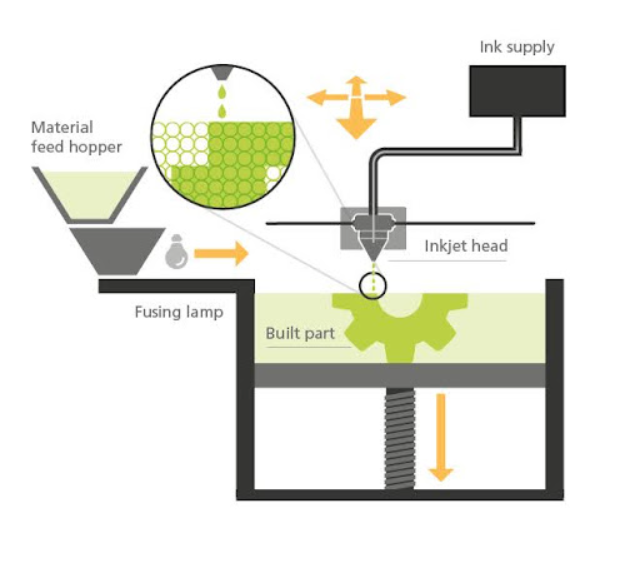

Multi Jet Fusion

Invented and Patented by Hewlett-Packard (HP) in 2016, Multi Jet Fusion (MJF) uses a high-intensity light source to selectively fuse particles of a material–usually nylon or polymers–to create an object in one step.

The process begins with a material layer that’s heated from below with a heater plate. The layers are then combined by jets of fusing and detailing agents.

Custom 3D Printing Benefits

Options of Various 3D Printing Technologies

An advantage of leveraging a custom 3D printing service is the access to various 3D printing technologies. This diversity offers an opportunity to create parts with varying characteristics simply by choosing the technology that best aligns with your custom manufacturing needs.

Additionally, with the various 3D printing technology options available, you can choose the option that matches your project requirements in terms of speed, precision, material compatibility, and cost-effectiveness.

Multiple Material Options

Custom 3D printing offers the flexibility and freedom to choose from the various material options available, including plastics, metals, ceramics, resins, and composites. This extensive material selection enables manufacturers to choose material properties that work best for their end product in terms of factors like strength, flexibility, transparency, and heat resistance.

Access to 3D Printing Expertise

Many custom 3D printing providers are experts in the field with skills that are essential in all stages of 3D printing production. These professionals and experts play important roles in design optimization, file preparation, material selection, choosing the best 3D printers for your manufacturing needs, and troubleshooting to ensure streamlined and hitch-free manufacturing processes.

These experts’ knowledge and experience also play important roles in helping you navigate potential challenges during the manufacturing of your product, thereby enhancing the overall quality of the final product. Using custom 3D printing means individuals or businesses don’t need to own, operate, or directly manage 3D printers themselves.

Custom 3D Printing Limitations

While custom 3D printing offers various benefits, it also comes with limitations that manufacturers need to be aware of. Some of these limitations include:

Custom 3D Printing Costs

While custom 3D printing is typically cost-effective for small-scale projects, it can quickly become expensive when it comes to large-scale projects. Beyond the initial costs of the tailored design itself, there are additional logistics and handling fees, especially when factoring in the unique requirements or materials needed for specific projects.

Shipping and delivery, given the delicacy of custom-made products, might entail specialized packaging or expedited transport, further inflating the budget. Additionally, revisions or modifications to an already-customized design can significantly amplify costs, given the need to restart the printing process or procure different materials.

As such, for individuals or small businesses, cost considerations may limit the accessibility of custom 3D printing for certain projects.

Reliance on Outsourcing

Outsourcing signifies delegating the production of custom items to an external service provider instead of crafting them in-house. This approach, though often beneficial for accessing specialized equipment and expertise, presents inherent challenges. A key concern is quality consistency; without direct oversight, there’s potential for variations in the final product’s standard. This disconnect can lead to unforeseen delays, be it from miscommunication, equipment malfunctions, or other logistical hiccups at the provider’s end.

Additionally, the provider’s capacity may not align with sudden demand surges, posing scalability issues. Finally, the financial dimension cannot be overlooked: while initial costs might seem lower, hidden fees and the expenses of addressing substandard outputs can accumulate, costing more in the long run.

Design Limitations

Although custom 3D printing is highly versatile, it is not without design limitations. Certain geometries and intricate details may be challenging to achieve, depending on the chosen 3D printing technology and material. This is because most printers have limitations on the size of objects they can produce, the materials they are compatible with, and other mechanical properties like the need for support structures in complex designs.

Additionally, while 3D printers can achieve very high resolutions, mastering these capabilities while fine-tuning and dialing into the parameters of the printing system might require patience. Designers and customers must understand that the final printed result may not always precisely match the customer’s initial expectations.

These limitations should encourage you to invest in your own 3D printers that can print custom products, allowing for greater control and adaptability in addressing design challenges and meeting specific needs. Investing in 3D printers can provide a unique edge in the production process, ensuring optimized results tailored to individual preferences and requirements.

Get Started On Your Next Custom 3D Printing Project

When the thought of owning and maintaining a professional 3D printer feels like a steep financial commitment, custom 3D printing services come to the rescue. These services present a cost-effective alternative, especially appealing to small businesses and individuals eager to delve into the world of 3D printing without the hefty upfront costs.

Yet, for those seeking more control over their product’s quality and production processes, purchasing a 3D printer is the best way to go. Nexa3D has a lineup of the best 3D printers, including the XiP Pro, NXE 400Pro, XiP, QLS 230/6, and QLS 820.

With Nexa3D’s ultra-fast 3D printers, you can unlock a new world of better manufacturing processes.

Ready to experience it yourself?