- Xometry Joins QLS 820 Manufacturing Partner Network - March 22, 2023

- Weerg Offers Quick-Turn Resin 3D Printing Service by Installing Four NXE 400Pro Printers - March 22, 2023

- Nexa3D Acquires XYZ Printing’s SLS Technology - March 19, 2023

We are thrilled to announce the acquisition of XYZ Printing’s SLS business, inclusive of technology, distribution, and service. Effective immediately, we will add the popular MfgPro230xS and MfgPro236xS printers to our powder bed product portfolio, further expanding access to affordable SLS printing technology to our combined customer base.

Over the past five years, the XYZ Printing technology has been successfully adopted by a wide range of customers, building a strong reputation for high-performance, high-speed printing with outstanding reliability. The MfgPro230 and MfgPro236 produce polymer components with tough, mechanical and thermal properties. Both printers use an open material platform and are compatible with a broad range of nylon powders, ideal for higher temperature applications.

“Our XYZ SLS machines offer something others do not, the ability to use end-of-life powder from our EOS and HP MJF machines for high-quality SLS parts. On top of the operational sustainability, the smaller build volume of the 230 allows for a 22-hour complete build cycle that only requires a 2-hour cooling cycle with zero negative effect on part accuracy or surface quality.“

– Oscar Klassen, CEO JawsTech

Open Platform Fast Cycle Sintering

MfgPro236 xS

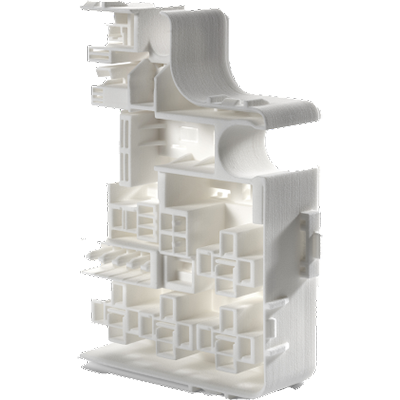

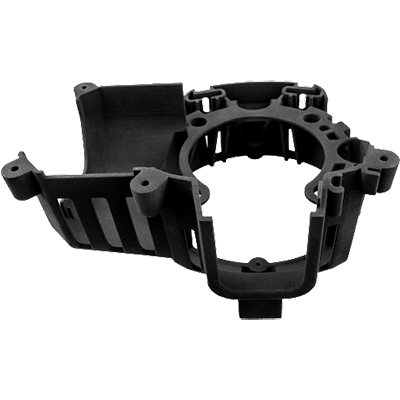

The MfgPro236 xS uses Selective Laser Sintering technology (SLS) to produce 3D printed parts with tough, mechanical, and thermal properties. Powerful features like 21 hour cycle speed, 60 watt laser, and 0.2mm accuracy, combined with an affordable and open powder portfolio, makes it the best value for professional users looking for an affordable but powerful selective laser sintering solution.

MfgPro230 xS

The MfgPro230 xS uses Selective Laser Sintering technology (SLS) and has long been the platform of choice for producing 3D printed parts with tough, durable mechanical properties. The MfgPro230 xS brings this capability to every prototyping user at an unprecedented value. With 24 hour cycle speed, 30 watt laser, and a broad range of materials it is undeniably the best entry-level printer for thermoplastic part production.

Broad Material Selection

Both printers offer a versatile range of materials including the popular PA11, PA12, PBT and PP, along with TPU88 and TPU75. Additionally, both systems are compatible with titanium and steel cold metal fusion materials.

Watch for more updates in the coming weeks as we work to combine and integrate our SLS product portfolio!