- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Selective Laser Sintering (SLS) is a 3D printing process that uses a laser to sinter and fuse powder particles into a three-dimensional structure.

SLS is an efficient, cost-effective, and precise additive manufacturing technique that has paved the way for more effective manufacturing processes across various industries, including aerospace, automotive, medical & healthcare, consumer goods, and much more.

SLS materials make this all possible. These 3D printing materials are known for their versatility and strength, allowing for the creation of complex, durable parts with high accuracy and detail. These materials can make everything from intricate jewelry to large-scale industrial components and are particularly well-suited for creating prototypes, functional parts, and custom designs.

This guide will highlight everything you need to know about SLS printing, the types of materials used, and the properties of these materials.

What is Selective Laser Sintering 3D Printing?

Selective laser sintering is known as laser sintering or laser powder bed fusion. It’s an additive manufacturing process and one of the many printing techniques in powder bed fusion (PBF).

SLS operates based on PBF technology by using a high-power laser beam to selectively combine polymer powder particles on a powder bed and fuse them to build a structure layer by layer. Sintering combines particles into a solid mass using heat and pressure, usually without melting or heating the particles to the point of liquefaction.

SLS is a more versatile and precise manufacturing solution than the traditional manufacturing process–especially since it creates true-to-scale and accurate designs with little to no human error.

Besides its accuracy and precision in creating parts from nothing but powders, SLS is preferred by engineers in various industries due to its high throughput and low cost of materials. This makes it a great technological solution for creating prototypes and end-use parts faster, a feat that is unachievable using conventional subtractive processes.

How SLS 3D Printing Works

As with any 3D-printing method, SLS begins with creating a CAD model of the structure to be printed. CADs are computer-aided designs created using computer-based software and are used to generate virtual models of the object to be printed, usually complete with a scale and intricate details. After the CAD is created, the file is then sliced into hundreds of 2D layers and transferred to the printer’s controller.

The polymer powder is dispersed into a thin layer on the build platform inside the printer’s build chamber. The printer then preheats the powder to a temperature just below the melting point, so the laser requires less energy to raise the powder’s temperature as it sweeps over it and solidifies it into shape. The laser then scans a cross-section of the CAD model, heats the powder, and fuses the particles into one layer of the model’s design. After that layer is completed, the printer lowers by one layer and repeats the process for another layer until all layers are completed.

The unfused powder from the bed supports the printing process, eliminating the need for printer support. After the printing process is completed, the excess unused powder can be collected and recycled for future manufacturing. This reduces waste and promotes sustainability, two features absent in traditional subtractive manufacturing processes.

After the model has cooled, it can be subjected to post-processing techniques such as cleaning, sanding, and painting.

SLS vs. HSS 3D Printing

SLS and high-speed sintering (HSS) are two leading polymer-based 3D printing processes. Although they both sinter and mold powder particles, they do so using two distinct methods.

SLS 3D printing uses a laser to deliver thermal energy to the powder bed and is a vector-style method where the laser, or lasers, draw the cross-sectional area of the parts on each layer. SLS is typically used for manufacturing structures made of materials such as nylon, polyamide, and thermoplastic elastomers, and it is mostly used to manufacture small to medium parts.

On the other hand, HSS is a raster-style method where an infrared (IR) heating element sweeps across the powder bed. The IR pass is preceded by a jetting pass, which deposits a fluid in a part’s cross-sectional area to increase IR energy absorption. HSS is best used for making small to medium parts.

SLS Material Review

Selective laser sintering supports a wide range of 3D printing materials, making it one of the most versatile PBF 3D printing processes.

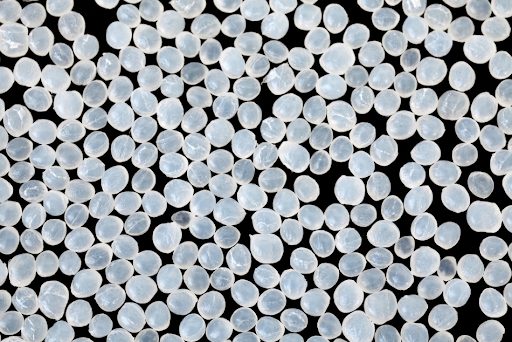

Polyamide (PA)

Polyamide is a synthetic polymer created by linking long and thin filaments with an elastic structure. Polyamides are often referred to as “nylon.”

Although there are various types of polyamides, the most commonly used ones in SLS printing are Polyamide 6 (PA6), Polyamide 11 (PA11), and Polyamide 12 (PA12).

- PA6 is an elastic fiber that regains its original shape after being subjected to stretching. It is stiff at high temperatures, has good abrasion, is considerably wear-resistant, has good fatigue resistance, possesses impressive electrical insulating properties, and has an excellent surface finish.

- PA11 is a high-performance plastic material made from renewable castor beans. It offers dimensional stability, impact resistance, abrasion resistance, and flexibility.

- PA12 is the most commonly used polyamide in SLS manufacturing, used for almost 90% of all industrial plastic production. PA12 offers grease and fuel resistance, high dimensional stability, low moisture absorption, good weldable ability, toughness, and impressive wear properties, making it a manufacturer favorite for SLS manufacturing.

Properties:

- Abrasion resistance

- Chemical resistance and substance opposition

- Corrosion resistance

- Electromagnetic obstruction

- Adaptability and versatility

- Strength and toughness

- UV light resistance

Polypropylene (PP)

Polypropylene is a synthetic thermoplastic polymer made from a combination of propylene monomers. It is tough, rigid, crystalline, and applied to various manufacturing processes across several industries, including the automotive industry and plastic-producing industries.

Polypropylene is commonly used in SLS 3D printing due to its excellent plasticity, high elongation, low hygroscopicity (moisture absorption), and excellent durability. It can create a wide range of products, including plastic parts for machinery, plastic packaging, and car bumpers.

Properties:

- Good surface finish

- Chemical resistance

- Flexibility

- Deformation resistance

- Lightweight

- Better strength-to-weight ratio

- Low melting point

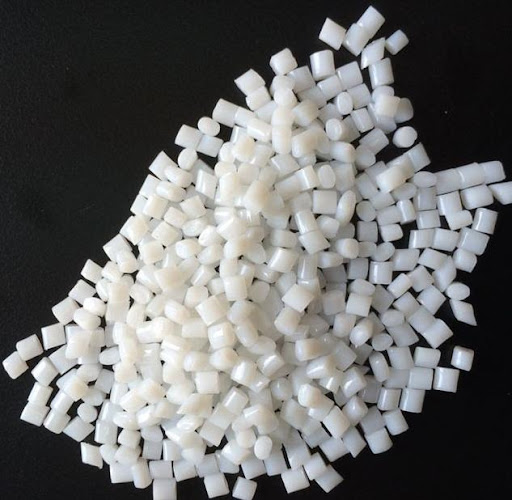

Polyethylene (PE)

Polyethylene is a lightweight and versatile synthetic thermoplastic resin created from the polymerization of ethylene. It can be categorized into forms such as low-density polyethylene (LDPE), high-density polyethylene (HDPE), and a polymer called polyethylene terephthalate (PET).

The most common forms of polyethylene used to 3D-print are HDPE and PET, which is mostly due to their strength, flexibility, durability, and ability to be recycled.

Properties:

- High chemical resistance

- Low coefficient to friction

- Maintains stability in cryogenic environments (under low temperatures)

- HDPE FDA/USDA approved

- HDPE is resistant to many solvents

- HDPE has excellent wear resistance

Thermoplastic Urethane (TPU)

TPU is a melt-processible thermoplastic elastomer. It possesses unique properties that offer superior processing capabilities, especially when subjected to SLS 3D printing. TPU can be melted down and reused, making it a more eco-friendly and recyclable option than most rubbers.

However, it can be difficult to work with due to the risk of shrinking and warping.

Properties:

- Flexibility

- Resistance to abrasion

- Smooth finish

- Increased printing accuracy

- High wear resistance

- Low-temperature performance

- Feasible for printing complex geometry

- Versatility

Thermoplastic Elastomer (TPE)

Also known as Thermoplastic rubbers, TPE is a diverse family of rubber-like materials that can be recycled like thermoplastic materials. While they may look and feel like rubbers, they are processed as thermoplastics, which means they have fewer processing steps and shorter fabrication times.

Like thermoplastics, TPE can be recycled, making them a sustainable option for manufacturing processes.

Properties:

- Lightweight and flexible

- Fatigue-resistant and good elastic recovery

- Abrasion resistant

- Resistant to low and high temperatures (up to 170 degrees Celsius)

- Good solvent resistance

Polymer-Coated Metal Powders

As the name suggests, polymer-coated metal powders are made by coating metal particles in a thin layer of polymer. It is used in various industries including automotive, aerospace, electronics, and medical devices. They are often used to produce high-strength, lightweight components that are resistant to wear, corrosion, and fatigue.

Polymers and metals are bonded together through a process called Cold Metal Fusion created by Headmade Materials. It’s a patented process that combines the advantages of fast cycle sintering with established powder metallurgy processes to create titanium and steel parts.

Cold Metal Fusion involving polymer-coated metal powders is a new and unique process only done by a few SLS printers in the market today. Using a polymer-coated metal powder, Nexa3D’s QLS230 and QLS236 produce “green” parts in a low-temperature processing environment. Parts then go through a secondary debinding and sintering process that burns out any remaining polymer and sinters metal particles together to form final metal components.

Learn more about the QLS230 and QLS236.

Polyketone

Polyketones are a family of high-performance thermoplastic polymers. They are often used in mechanical and automotive industries as fuel lines and to make products such as housings or switches.

Properties:

- High impact strength

- Excellent chemical resistance to automotive hydrocarbon solvents, salts, and weak acids/bases

- Excellent wear resistance

- Exceptional barrier properties

- Non-toxic

Polybutylene Terephthalate (PBT)

PBT is a strong and highly crystalline polymer that is utilized in various industries, including engineering and biomedical fields. It is a high-performance material known for its impressive properties such as durability, mechanical strength, and heat resistance, all of which are factors that make it a good option for SLS printing.

Properties:

- Excellent strain resistance

- Good creep resistance

- Low moisture absorption

- High strength

- Stiff

- Tensile strength can be increased up to three times through glass-reinforcing

Benefits of SLS 3D Printing

Unlike other 3D printing techniques, such as HSS, SLS 3D printing has access to a wide range of materials, allowing it to create 3D structures with various properties suitable for various industries.

When it comes to using a wide array of materials for SLS 3D printing, Nexa3D’s printers lead with a wide margin compared to many printers in the market today.

Nexa3D’s QLS 230 SLS printer is an open platform with 10+ qualified nylon and metal fusion materials, including a range of Polyamides, PP, PBT, and TPU. The QLS 230 is also compatible with Cold Metal Fusion by Headmade Materials, a patented process combining fast cycle sintering with established powder metallurgy processes to create titanium and steel parts. The QLS 230 also performs exceptionally well using recycled powders from HP and EOS, thereby offering operational stability and sustainability in all its operations.

Varied Build Volume

One major advantage of SLS printers is the absence of support structures which makes it easier to create large-volume structures. The absence of support structures in SLS makes it easier for SLS printers to manipulate powder into free-form geometries, making it easier to make complex and intricate structure designs.

Other 3D printers, like Fused Deposition Modeling (FDM) printers, require support structures to keep the structures being built fixed to a base plate during the building process. However, SLS printers use unsintered and infused powder as support, making it easier to print parts in batches accurately.

SLS printers also provide large build capacities – typically around 300 x 300 x 300mm but can reach up to twice this number– letting operators and manufacturers pack the build chamber with as many parts as it can print. SLS printers also have small build volumes which is great for lower costs and less material usage.

Reusing of SLS Materials for Reduced Waste

Not all SLS 3D printers support sustainable printing processes, which is why choosing a machine that prioritizes sustainable manufacturing is essential.

Some machines require new powder more frequently than others, resulting in unused powder that must be disposed of. How the powder is used also affects waste, with larger builds requiring more powder and creating more waste. In comparison, smaller builds need less powder, print, and cool faster, resulting in less waste, higher throughputs, and lower printing costs.

It’s also important to consider the machine’s material requirements before investing in it, as some machines are designed to work with specific materials from specific manufacturers, making it harder to find affordable or eco-friendly materials.

Nexa3D’s printers make it easier for manufacturers to reuse powders efficiently. The QLS 230 and QLS 236, support reduced manufacturing waste by using an open material platform to print reusable thermoplastic powders.

Control Over the Printing Process

Unlike 3D printing techniques, such as HSS, which has somewhat of a ‘push-button’ approach where the printer takes control of the process, SLS places control in the technician’s hands. While this means SLS printing requires technical know-how, it also provides an opportunity for technicians to supervise the process and alter the production when they feel the need to.

Use the Best SLS 3D Printer & 3D Printing Materials

While various SLS printing materials are available in the market, they’re not always compatible with every 3D printer. Using an SLS 3D printer that offers an open material platform allows you to use the perfect material for your product at your desired price.

At Nexa3D, we believe in the power of an abundant material ecosystem–all of our SLS printers offer an open-material platform. We also continue to partner with leading material providers to deliver a comprehensive range of high-impact functional materials that are tailored to your mechanical requirements and performance needs.

The QLS printer series in our catalog offers exceptional SLS printing benefits, including high throughput, swift printing, better workflows, and high-quality structures that can be used as prototypes or end-use materials.

We know 3D printing is an investment, so we’d love to take the time to speak with you, answer any questions, and determine how any printer from the QLS series can revolutionize your production process.

Gain a deeper understanding of SLS 3D printing with our SLS 3D Printing Production Readiness Guide.