Murtfeldt turns to Nexa3D to Increase Throughput, Accuracy, and Consistency

When Murtfeldt AS needed speed and precision, it turned to the NXE 400 to produce critical electrical connectors

Founded with a mission to connect engineering with the technology of selective laser sintering, Johannes Matheis created Jomatik in Germany in 2014, offering not only 3D printing but also support throughout the entire product development and production process. Then in 2020, Murtfeldt Group acquired the business and renamed it Murtfeldt Additive Solutions GmbH.

The company prides itself on providing a full suite of services, from technical consulting to helping create a design plan, to 3D data development and solutions, and finally production via additive manufacturing. Murtfeldt has increasingly focused during the past couple of years on delivering effective post-processing of all components, from surface finishing to thread inserts. Driven to deliver the solutions its customers need, Murtfeldt AS recently acquired its first photopolymer printer from long-time Nexa3D reseller ProductionToGo (PTG), a unit of Disc Direct Handels GmbH.

Challenge

Murtfeldt had a new customer that needed to produce a specific type of high-resolution electrical connector requiring extreme precision as well as an excellent surface finish in order to be effective. The team determined that it could not achieve its aims using its existing SLS or FDM equipment, so they worked closely with ProductionToGo to investigate available alternative technologies.

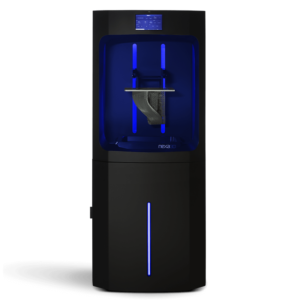

NXE 400 industrial resin 3D printer from Nexa3D provides an ultrafast production solution for the team at Murtfeldt Additive Solutions.

“After benchmarking, it became clear that only the Nexa3D machine provided the required part performance with an appropriate material, combined with the high throughput that was needed,” explained Maximilian Neck, PTG’s head of additive manufacturing. “They essentially bought the Nexa3D NXE 400 in order to fulfill this customer and this project.”

Post-sale, PTG provided Murtfeldt with user training, benchmarking and other support, as well.

“We found the ideal solution for the end user by bringing in the Nexa3D machine. If we had chosen any other technology, we likely would have needed more than one printer to match that output”

Johannes Matheis, CEO of Murtfeldt AM

Customer

Murtfeldt Additive Solutions GmbH

Industry

Electronics

Products

- NXE 400

- Nexa3D xABS3843-Black

Application

Produce high-volume, high-resolution, highly consistent parts

Advantages

- Produced results not possible with SLS or FDM

- Larger build plate, faster print speeds

- High-volume throughput

- Excellent accuracy, repeatability and surface quality

Solution

Murtfeldt is very happy with the Nexa3D printer, which is installed at Murtfeldt AS’ plant in Tübingen, Germany, near Stuttgart. For the connector, Murtfeldt is using Nexa3D’s xABS material, which provides “superior mechanical performance” for the application in question, Neck said. Using the NXE 400 and its LSPc technology, Murtfeldt is able to produce about 12 connectors per hour. In the first two full months of production, the company has made some 2,400 connectors for their customer.

Parts printed on NXE 400 using xABS Black show off complex geometry with high resolution and precision.

“We found the ideal solution for the end user by bringing in the Nexa3D machine,” says Murtfeldt CEO Johannes Matheis. “If we had chosen any other technology, we likely would have needed more than one printer to match that output” due to the competitors’ smaller build plate and longer print times.

This purchase has now given Murtfeldt the ability to produce high-quality, high-resolution components for other customers, as well, he noted. In fact, PTG is already working with Murtfeldt to validate use of the NXE 400 for a new job for another customer that involves manufacturing flexible parts using Nexa3D’s xFLEX475 material.

“After doing the validation together with our partner ProductionToGo,” Matheis said, “we chose the Nexa3D machine for the connector project because of its superior throughput speed, high resolution and amazing consistency. Our customer is delighted with the end result.”

Johannes Matheis, CEO of Murtfeldt AM