Revolutionizing Flight Simulation with XiP Desktop 3D Printer

Working with engineering experts at MotoCilino, the team commercialized a handheld flight controller in record time

In an industry where speed, accuracy, and cost-effectiveness are crucial, Yawman Flight teamed up with MotoCilino Engineering Service firm and Nexa3D to address the challenge of designing and developing a first-of-its-kind handheld controller for flight simulations.The Yawman Arrow is the fusion of a traditional handheld gaming controller and the unique flight controls found on aircraft of all sizes. Designed for precision and versatility, the Arrow brings together a traditional joystick, desktop throttle quadrant, and rudder pedals – and more – all into a handheld form factor.

The result is a breakthrough in both product innovation and manufacturing efficiency, with XiP Desktop 3D Printer playing a pivotal role in achieving success.

Challenge

Create high-fidelity prototypes quickly and cost-effectively without investing in tooling early on in the development process

Yawman Flight faced the challenge of creating a unique flight simulator controller under significant time and budget constraints. The primary objectives were to develop a first-of-its-kind handheld flight simulator controller and complete the project rapidly and cost-effectively, without investing in costly injection molding tooling. Additionally, the team required high-quality surface finish and mechanical performance of all of the components so achieving injection molding-like quality quickly and affordably were critical to the success of the project.

Yawman Flight’s intended customer base is flight simulation enthusiasts and professionals in the aviation industry who demand high-quality, realistic flight simulation experiences. The flight simulation industry requires high-quality products that can meet strict specifications for part tolerances and mechanical performance in order to provide a truly realistic simulation experience.

“The XiP allowed us to create a final product that exhibits injection molded like qualities in terms of surface finish and performance, but without the costs and long lead times. We would’ve been delayed by as much as a year had we used another manufacturing method during the prototyping phase.”

Thomas Nield, Engineering Lead at Yawman Flight

Customer

Yawman Flight and MotoCilino

Industry

Aviation

Products

- XiP Desktop 3D Printer

- xABS3843 Resin

Application

High-Fidelity Prototyping

Advantages

- Rapid production of high-fidelity prototypes

- Tens of thousands dollars saved in tooling costs

- Injection molding-like surface finish and mechanical performance

- Reliable, high-speed desktop 3D printing with high performance resin

Solution

The XiP proved to be ideal tool for the job due to its accuracy and print speed

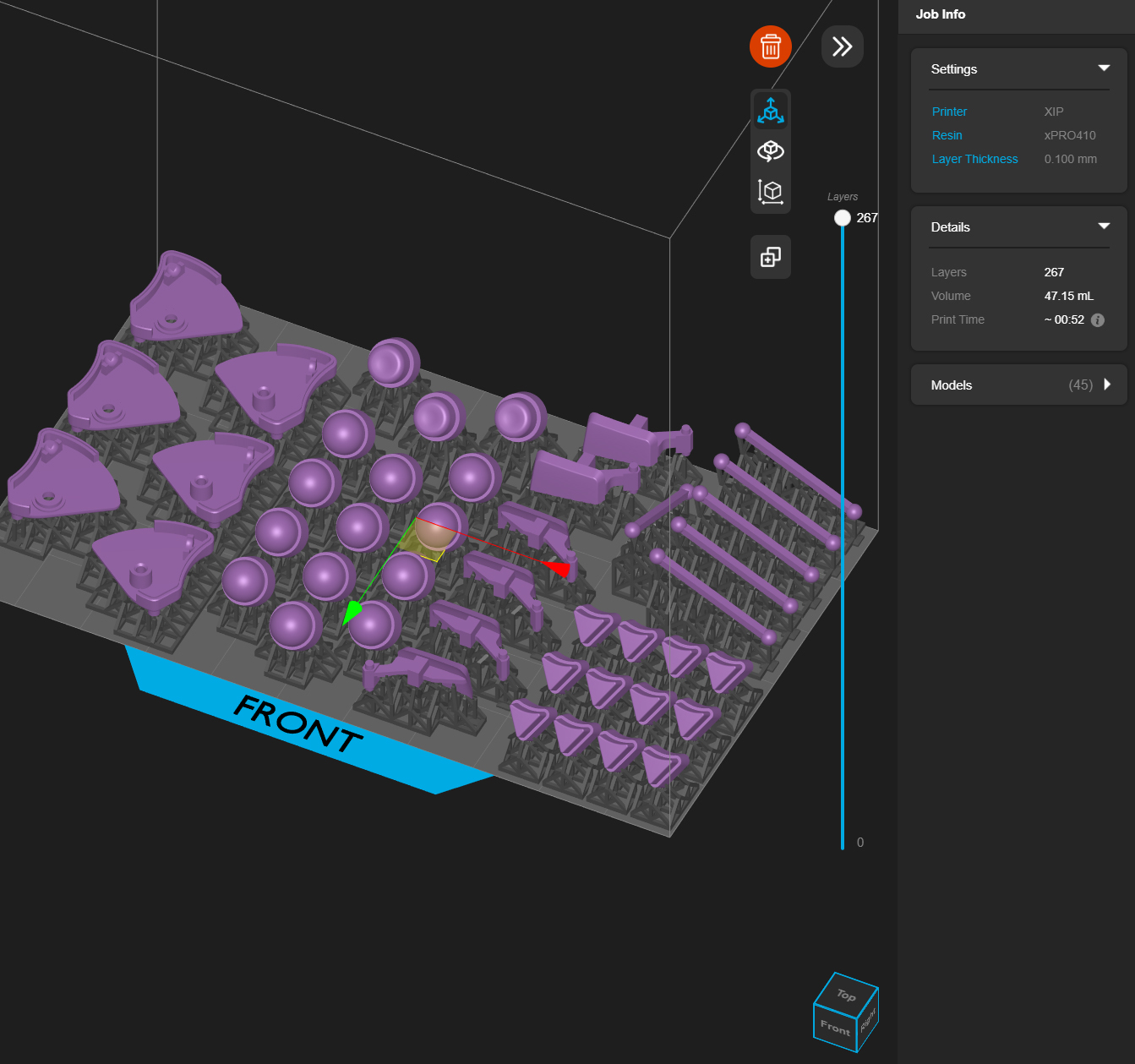

Yawman Flight collaborated with MotoCilino Engineering Service firm to develop a unique controller in record time, going through 17 different design iterations before validating the final assembly in just a few weeks. The final prototype controller consists of 36 different components, all of which were printed on the XiP desktop 3D printer using xABS3843 high-performance resin.

The team at MotoCilino chose to print the components on the XiP due to printer’s reliability and high print quality using performance grade resin that mimic mechanical properties of final production grade ABS. In fact, the finished controller visual aesthetic and mechanical performance was virtually indistinguishable from those components that were molded. “Printing on the XiP allowed us to deliver components to the Yawman team in half the time it would’ve taken us had we used another desktop SLA printer, and the print quality on the XiP is just superior,” said Paul Cilino, Owner of Motocilino.

Benefit

Accelerated time to market by nearly a year and delivered high-fidelity prototypes at a fraction of the cost

The team was able to finalize the design and deliver a high quality prototype with injection molding-like surface finish and mechanical performance quickly and cost effectively. The finished assembly included over 36 printed components, all virtually indistinguishable from its injection molded counterparts in both finish and mechanical performance. As a result, the team is now ready to scale to production as they prepare for commercial launch in July, 2023, on the heels of tremendous initial demand received during its beta launch earlier in the year.

Learn more about the XiP Desktop 3D Printer by requesting a free sample today.