Prototypes in One Day with Lower Tooling Costs

Growing up around traditional manufacturing, the founder of Optomiz3D knew that there was potential for a business that joined the best of both worlds— that vision was realized with the NXE 400.

Optimiz3D is a start-up contract manufacturer specializing in both 5-axis CNC manufacturing and 3D printing services. Their services include on-demand production of prototypes, short-run manufacturing as well as custom production applications.

Founder, Miha Koprivec began his career in a family business owned by his father. This company was a part supplier and manufacturer of technical products made of elastomers and thermoplastics, mainly serving the automotive industry. “I saw an opportunity for 3D printing in this type of industry. It was not common, but I saw a real value in 3D printing for serial production of parts and not just product design,” says Koprivec.

Traditional Meets Next Gen Production

Optimiz3D’s business model relies on the ability to offer high value manufacturing and fast turnaround times through combined specialization in 5-axis CNC manufacturing and 3D printing.

Powering a New Business Model

The NXE 400 provides Optimiz3D the agility and flexibility to produce parts that make sense for a wide variety of client needs, maximizing turn times and profitability.

Finding the Right Printer for the Job

Adding 3D printing to a traditional manufacturing mix yields many benefits, including higher productivity, and ultimately increased ROI.

Immediate Impact

After purchasing the NXE 400, Koprivec quickly realized how big of an impact it made to be able to deliver a prototype within one day instead of weeks. “It’s given our business and our customers a real advantage. They are able to evaluate their designs faster, modify their designs easier, and even run small series production with us at record speeds,” Koprivec says.

In one case, working with a customer in the machine production industry, Optimiz3D was able to offer their 3D printing services as a solution over injection molding, saving the customer a significant amount of time and money.

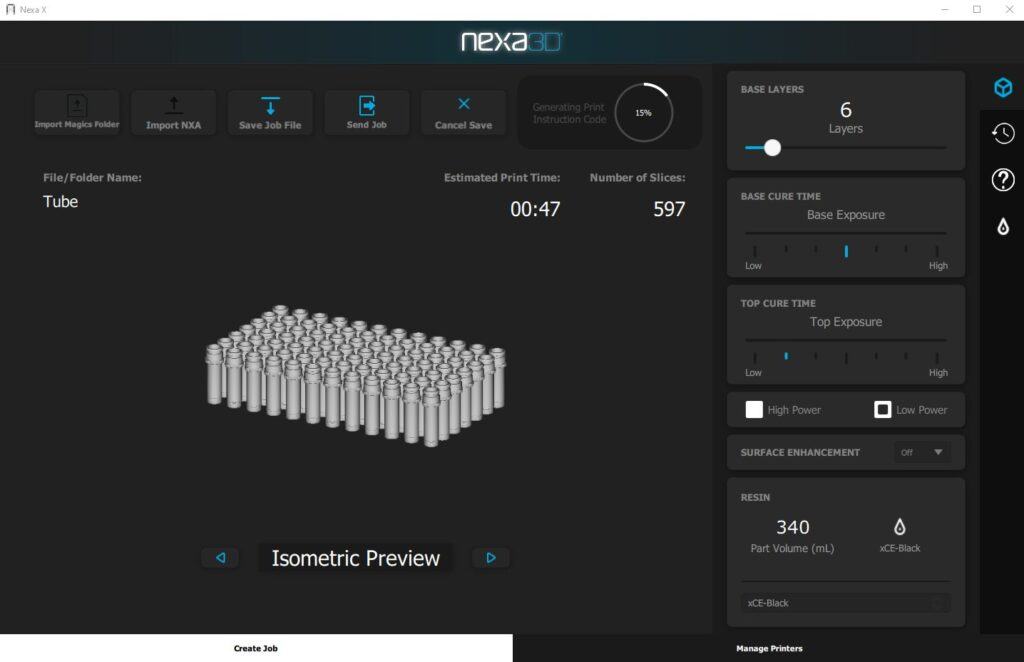

“The part is a tube diameter 15mm and 60mm long,” Koprivec says. ‘’Normally this part would be injection molded out of PA6GF15 material. For this specific part we used xCE-Black material which has excellent mechanical properties and high temperature resistance, as this was the customer’s requirement. The main benefit of 3D printing in this case is the tooling cost, which is zero, thus lifetime project cost is smaller than in the case of injection molding.”

“It’s given our business and our customers a real advantage… to evaluate their designs faster, modify their designs easier, and even run small series production with us at record speeds.”

Miha Koprivec – Founder, Optomiz3D

Unexpected Benefits

In addition to the cost savings, other benefits included a fast production start and the flexibility to implement later design modifications without expensive tooling changes.

Download PDF