- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

3D printing has emerged as a transformative force in the healthcare industry, reshaping the way the world approaches patient care and custom health solutions. One of the standout uses is 3D printed orthotics. From improved manufacturing speeds to the creation of accurately customized products, 3D printing is streamlining orthotics customization and production to address various foot health needs.

This article explores the process of how 3D printing orthotics works, some great 3D orthotic printing companies, and some of the best 3D printers for printing orthotics.

What Are 3D Printed Orthotics?

3D printed orthotics are custom-made insoles or inserts for shoes created using 3D printing technology. They’re wearable medical devices that correct biomechanical issues such as the inability to run, walk, or stand properly due to foot-related problems such as flat foot, pronation, or foot arch problems.

How 3D Printing Orthotics Works

Creating 3D printed orthotics involves taking precise measurements of an individual’s foot or leg, understanding their walking or running style, designing a custom orthotic based on this data, and then 3D printing it.

Let’s break this down step by step:

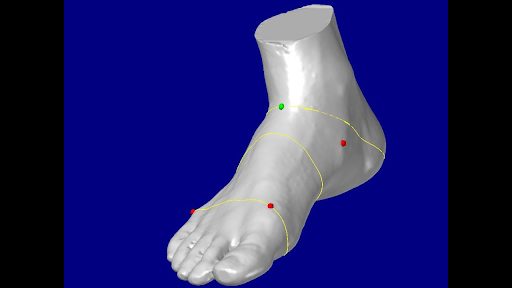

1. Foot & Leg Volumetric Scanning

Foot and leg volumetric scanning involves using advanced scanning technology, often laser or structured light technology, to capture precise measurements and contours of the individual’s feet and legs.

By scanning the patient’s limb, podiatrists can collect extensive data sets to generate a 3D image that provides an accurate impression of a limb for custom creation of the orthotic device needed. The volumetric data undergoes digital processing using computer software analysis to construct a comprehensive and accurate 3D digital model.

This model serves as the map for designing custom orthotic devices that will perfectly suit the patient’s unique anatomy and specific requirements.

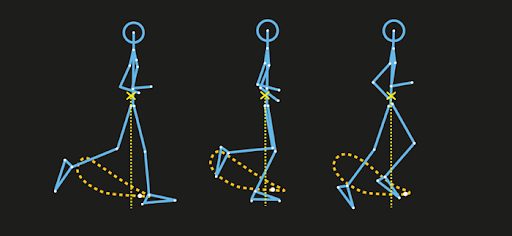

2. Gait Analysis

Gait analysis involves observing and analyzing the way an individual walks and runs to assess data such as stride length, foot pressure distribution, heel placement, pelvic angle, and any other factors or irregularities in the gait pattern. It is performed using various methods, such as computerized video cameras that show movement in slow motion.

During the analysis, the podiatrist places markers on the patient’s legs and feet to monitor motion on camera. The motion on video is observed frame-by-frame to collect data about the individual’s gait.

The data collected during gait analysis is essential to understanding how the patient’s feet and legs function during everyday activities, helping to identify areas where orthotic support is needed.

3. Orthotic Design Generation

With the necessary data collected during volumetric scanning and gait analysis, orthotic specialists and healthcare professionals can proceed to the design phase.

The professional analyzes and modifies the data collected from 3D scans and cleans them up using software like Meshmixer or Meshlab before exporting them to CAD software for further modification. This allows you to design an orthotic device customized for the patient’s unique anatomy and specific requirements. The orthotic device is then adjusted to address user problems like arch height, pressure points, and gait abnormalities while optimizing support, stability, and comfort.

4. 3D Printing the Orthotics

Once the orthotic design is ready, it’s sent to a 3D printer. Depending on the type of printer and material used, the machine will print the orthotic layer by layer until the final product is achieved.

3D Printing Orthotic Technologies

Different 3D printing technologies, such as SLA (Stereolithography) and SLS (Selective Laser Sintering), and various materials can be used, each offering unique benefits.

- SLA: SLA is a form of vat photopolymerization, a resin 3D printing technique that makes objects by selectively curing photopolymer liquid resin through light-activated polymerization. With SLA, the build platform is lowered into or raised out of a vat of liquid photopolymer resin during the process.SLA resins come in different formulations, offering various properties such as flexibility, transparency, or high heat resistance. It’s a great option for creating 3D printed orthotics because it creates highly detailed, intricate, customized structures, ensuring orthotic devices fit every patient comfortably and effectively.

- SLS: SLS uses a laser to fuse small particles of various materials like plastic powders into a solid object. The process is known as sintering, providing accurate energy enough to diffuse a particle across the boundaries of another material. It works by heating a bed of powder material with the laser to melt parts of the powder selectively. Once melted, the powder solidifies and forms a layer of the desired part shape. A new layer of powder is added above this melted layer and subsequently melted and fused to the layer below. This process is repeated until the entire part has been constructed.SLS is used in Orthotics because of its fast print speeds, ability to produce strong and consistent parts, and use of various materials, which allows for the production of parts with a wide range of properties.

3D Printing Orthotic Materials

The choice of material is crucial in determining the orthotic’s comfort, durability, and effectiveness. The chosen material influences the orthotic’s flexibility, durability, and cushioning properties.

Common materials include:

- Thermoplastics such as Thermoplastic Polyurethane (TPU)

- Photopolymer resins

- Carbon fiber

Benefits of 3D Printed Orthotics

Using Dynamic Data

Traditional orthotic methods rely on static foot impressions, while 3D printing uses dynamic data from volumetric scans and gait analysis. This ensures the orthotic addresses not just the static shape but also the unique movement patterns of the foot.

The result is a device tailored to the individual’s unique walking or running style, offering more effective relief and support.

Faster Orthotic Creation

3D printing speeds up the orthotic production process. Once the design is finalized, the orthotic can be printed within hours, eliminating the lengthy waiting periods associated with conventional methods. This rapid turnaround benefits patients who need timely interventions.

Better Results

3D printed orthotics are accurately customized to fit a patient’s needs, ensuring they provide superior results compared to traditionally produced orthotics. Because 3D orthotics take into account not only foot shape but also gait and movement, patients receive optimal support for their foot-related challenges.

This personalized solution alleviates discomfort such as joint or muscle pains, enhances foot health, and even improves gait.

Benefits of 3D Printed Orthotics for Clinicians

Reduced In-office Inventory

3D printing offers an opportunity to build orthotics on demand, reducing the need for extensive in-office inventory typical to traditional orthotics production. This requires less storage for items that may or may ever be needed.

True Customization

Clinicians create 3D-printed orthotics that address a patient’s specific anatomical and biomechanical needs and feet characteristics. This personalization not only means orthotic devices are made “true-to-size” but also created as a specific solution to a patient’s issues.

This true customization leads to better treatment results in patients.

Higher Revenue Opportunities

Revenues from 3D printed prosthetics, orthotics, and audiology are expected to reach an estimated $1 billion by 2030. Many patients are more willing to invest in a custom product that promises better comfort and faster results.

Additionally, the efficiency of the 3D printing process means clinics can potentially serve more patients in less time, enhancing profitability.

Environmentally Friendly

3D printing manufacturing techniques typically generate less waste than subtractive techniques that involve cutting down materials for production. This makes it a sustainable and environmentally friendly option for creating orthotics while demonstrating a commitment to eco-conscious health practices and sustainable manufacturing.

However, it’s important to note that the level of sustainability varies with the type of printer being used for manufacturing processes. Some printers, like Nexa3D’s QLS 236 and QLS 230, are more sustainable than others, thanks to their use of energy-saving features that enable low power consumption, functions that reduce toxic emissions, and zero-waste printing capabilities.

They also have material flexibility and an open-source platform that allows the use of recycled powders from HP® and EOS.

Challenges of 3D Printing Orthotics

3D Printed Orthotics Price

The primary challenge of 3D printed orthotics is their potentially higher cost compared to mass-produced alternatives. 3D printed orthotics can range from $300+ compared to traditional alternatives that cost between $60-$80. However, it’s crucial to consider the immense benefits they offer, such as precise customization and better treatment outcomes.

3D printed orthotic prices reflect the advanced technology, individualized care, and enhanced comfort they provide, making them a valuable investment for those seeking superior foot support and relief from orthopedic issues.

Access to 3D Printed Orthotics vs. Traditional Orthotics

In some regions or areas, finding a facility that offers 3D printed orthotics can be difficult. This limited access means that patients might have to travel farther or wait longer to get their 3D printed orthotics.

3D Printed Orthotics Services

Here are some companies that make 3D printed orthotics.

1. iOrthotics

iOrthotics is an American 3D printing center that specializes in creating custom-made orthotic devices. It is a joint venture between iOrthotics Australia and Hersco Ortho Labs. They create solutions such as personalized insoles and inserts tailored to an individual’s unique foot anatomy and movement patterns.

Features & Services:

- 3D printing services

- Sustainable production practices

- University testing and research

- Production of strong, lightweight orthotic devices

2. Evo

Evo is a company dedicated to providing a wide range of foot-related solutions such as toe lengthening and 3D orthotics. The company, in conjunction with HP, uses biomechanical metrics to capture real-time data while patients walk and compile it to produce a model of the feet during stance and motion.

Features & Services:

- 3D volumetric Scan

- Real-time GAIT scan

- 3D orthotic printing

Best 3D Printers for Orthotics

There are several different 3D printers suitable for printing orthotics using technologies ranging from selective laser sintering printing to fused deposition modeling.

1. QLS 230

Nexa’s QLS 230 is the most affordable open-platform SLS 3D printer suitable for industrial use. It offers a swift 24-hour cycle speed using a single 30-watt CO2 laser to produce prototypes with robust mechanical and thermal properties.

The QLS 230 uses an open platform that works with 10+ qualified nylon and cold metal fusion materials–meaning it can produce titanium and steel parts. It also excels with third-party materials like recycled powders from HP and EOS, ensuring ultimate operational sustainability. Combined with its powder refresh rate of just 20%, the QLS 230 has the lowest entry point in the professional SLS market.

Key Features:

- 230 x 230 x 230mm build volume

- Cold metal fusion compatibility

- Compatible with 10+ qualified nylon materials

- Utilizes waste or recycled powder from HP and EOS

- Build speed up to 20mm per hour

2. QLS 236

The QLS 236 is another powerhouse open platform selective laser sintering 3D printer with a swift and unrivaled 21-hour cycle speed. It uses a single 60-watt CO2 laser to create prototypes and production parts from a broad range of high-temp thermoplastic materials.

A versatile, open-platform printer, the QLS 236 works with qualified materials like Polyamides, PP, PBT, and TPU, as well as patented metal powders from headmade materials®. In addition, it excels with recycled powders from HP and EOS to extend the life of your powders and provide operational sustainability.

Key Features:

- 230 x 230 x 250mm build volume

- 20% powder refresh rate

- One of the lowest costs of entry in the SLS printer market

- ColdMetalFusion compatible

- Powered by two advanced intuitive software suites, Buildware, and XYZprint AMsLs

3. XiP Pro

Nexa3D’s XiP Pro is the world’s fastest and most powerful resin 3D printer that offers a high production throughput at the lowest cost of operation. It features the largest build volume and fastest print speed in its class, offering unrivaled control over the production of functional prototypes and final-use parts at previously unattainable production economics.

The XiP Pro features state of art, LCD-based VAT photopolymerization process using the patented Lubricant Sublayer Photocuring (LSPc) technology to deliver high accuracy, excellent dimensional stability, and superb surface quality. Its open versatile open platform offers a range of manufacturing materials, from durable 3D printer resins including xABS and xCE to elastomeric materials, like xFLEX475 and xFLEX405.

Key Features:

- 19.5L build volume

- Intuitive NexaX Software & Smart Resin Delivery System

- Environmental Monitoring System

- Large industrial capacity and compact footprint

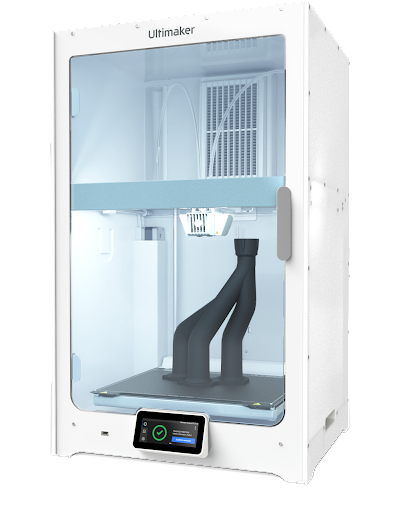

4. Ultimaker S7

The Ultimaker S7 offers a large build volume, making it a top choice for a wide range of applications. With dual extruders and advanced features, it delivers reliable and detailed 3D prints, a suitable option for professionals and businesses.

Key Features:

- Anti-flood sensor and integrated air manager

- Print with 280+ materials

- Flexible build plate with sensor

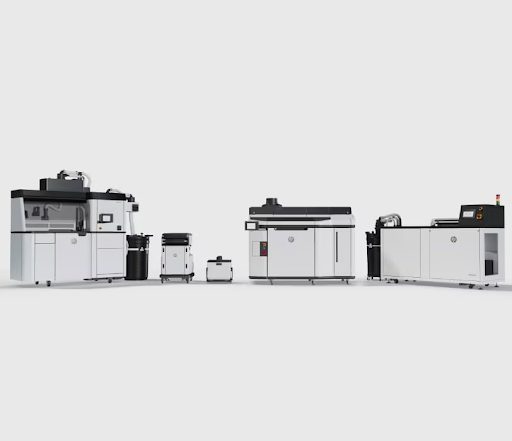

5. HP Multi Jet Fusion

HP Multi Jet Fusion is a rapid 3D printing technology designed for industrial production. It is known for its speed and efficiency in creating functional parts at scale. However, it has limited control over intricate details compared to some other 3D printing methods.

Key Features:

- High-volume production cycle

- Multi-material printing

- Digital workflow

Are 3D Printed Orthotics Worth It?

Navigating the landscape of 3D printed orthotics presents both promise and complexity. These orthotics offer the potential for a highly personalized approach to foot care, with quicker production timelines.

However, their effectiveness is closely tied to the quality of the technology and equipment in use. Leveraging reliable and advanced tools, such as those provided by Nexa3D, can significantly enhance the benefits of 3D printed orthotics.

Nexa3D blends speed, precision, and accuracy to offer unprecedented solutions for the creation of custom orthotics with the utmost precision. With technological solutions offered by Nexa3D’s range of 3D printers, the future of foot health is marked by efficiency, comfort, and mobility.

Are you ready to explore it yourself?