- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Whether you are producing prototypes, jigs and fixtures, production parts, or managing other professional projects, selecting the most suitable 3D printing material for your project is essential.

There are various categories of 3D printing materials including plastics, metals, and composite polymers. Each of these categories contains a range of different material types used in each 3D printing method.

This article will cover some of the most common 3D printing materials, their properties, and 3D printing applications.

3D Printing Material Types

There are four main categories of 3D printing materials. These include:

1. Plastic Material

Plastic is one of the most common 3D printing materials. Thermoplastics in particular are a great 3D printing material since they become soft and moldable when heated and then return to solid form when cooled, making them perfect for powder bed fusion and extrusion-based 3D printing technologies

These materials exhibit a wide array of different properties like strength, flexibility, and heat resistance. Examples of thermoplastics include:

- ABS (Acrylonitrile butadiene styrene): ABS is an affordable filament with good impact and abrasion resistance. It’s often used for automotive parts, building and construction, and electronic housings due to its chemical resistance.

- PLA (Polylactic acid): PLA is a biodegradable plastic made from renewable resources like fermented plant starch. It’s by far the most common material used because of its ease of use and low cost. PLA undergoes minimal expansion and contraction when heated and cooled.

- PETG (Polyethylene terephthalate glycol ): PETG is well known for its high chemical resistance and good thermal stability. You can use this food-safe material for producing plastic bottles, protective parts, and food containers.

- TPU (Thermoplastic polyurethane): TPU is a flexible material that can stretch and bend without breaking. TPU is used for creating prosthetics and other medical devices that require this flexibility as well as flexible components for consumer products and prototypes.

- Nylon: Nylon is a strong and flexible thermoplastic best for creating prototypes and functional parts used in rugged environments requiring chemical resistance and excellent mechanical performance.

- PEEK (Polyether ether ketone): PEEK is well known for its good chemical, thermal, and mechanical resistance. It is mostly used in the engineering, automotive, and medical industries.

- PVA (Polyvinyl alcohol): This thermoplastic is soluble in water and is often used as a support material.

3D Printing Technologies that Use Plastic

Here are a few 3D printing methods that use plastic materials:

- SLS (Selective Laser Sintering): SLS selectively fuses powdered plastic particles using a CO2 laser to produce strong, complex parts. This process typically uses nylon powders like PA 6, PA 11, and PA 12 as well as some TPU and polypropylene powders.

- FDM (Fused Deposition Modeling): FDM or FFF (fused filament fabrication) is a form of material extrusion 3D printing. Many thermoplastic materials are available in filament form and filament extruders are often used to fabricate filaments from common thermoplastics like ABS, PC, PA 12, PEEK, and PPSU.

2. Metal Materials

Metals 3D printed. Image Credit: Assemblymag

Metal 3D printing fuses metal particles using high temperatures derived from lasers or electron beams. The process creates metal objects by melting or welding layers of metal or metal powder until a part is complete.

Here are some materials used in metal 3D printing:

- Copper: Copper’s high thermal conductivity makes it an excellent material for metal 3D printing. It’s often used for electrical engineering devices, manufacturing components, and communication antennas.

- Stainless steel: Stainless steel is durable, resistant to corrosion, and can withstand high temperatures. It can create components that can survive in harsh environments.

- Titanium: Titanium is a strong and lightweight metal commonly used in the medical and aerospace industries. It’s well-suited for 3D printing prosthetic limbs because it’s strong enough to support the limb’s weight while also being lightweight enough not to cause discomfort for the wearer. Its biocompatibility also makes it well-suited for use in the human body.

- Inconel® 625: Like stainless steel and titanium, Inconel® 625 has high strength, excellent corrosion resistance, and can withstand high temperatures. It is used in various industrial applications including marine engineering and the aerospace industry.

- Tool steels: Tool steels are commonly used in metal 3D printing due to their high hardness, wear resistance, and toughness, They can withstand high printing and post-processing temperatures without deforming or becoming damaged. They can also resist thermal and mechanical stress without cracking or breaking. They are usually used in the production of cutting tools, stamps, and molds.

3D Printing Technologies that Use Metal

These 3D printing methods can use metal materials:

- Powder Bed Fusion: This technology works by melting and fusing metal powder layer by layer to create the object. You start the process by spreading the metal evenly over a build platform, and the platform is raised for each new layer. Then, a laser or electron beam is used to melt and fuse the metal powder. The laser or electron beam is guided by a computer-controlled movement system, which directs it to the precise locations where melting and fusion need to occur. As the metal powder melts and fuses, it solidifies and bonds with the previous layer. This process repeats until the entire part has been built up layer by layer.

- Binder Jetting: The binder jetting process begins with a bed of powder from metals. The powder is spread evenly over the build area, and the print head moves back and forth across the powder bed, jetting the binding agent onto the powder. The binding agent adheres the powder particles together and forms the shape of the part. Parts are then taken through a sintering process where the bound metal powder sinters together to form the final metal part.

- Direct Metal Laser Sintering (DMLS): DMLS uses a high-power laser to fuse small metal particles to create an object. Like in binder jetting, the DMLS process begins with a bed of metal powder spreading evenly over a build platform. The powder is then selectively fused by a high-power laser as directed in the CAD file. The laser melts the metal powder, which fuses with the powder below it, creating a solid layer.

- Directed Energy Deposition: Direct energy deposition adopts the same principle as powder bed fusion, but instead of fusing material on an existing bed of powder, the powder (or in other cases, wire) is simultaneously fed through the nozzle and fused by a laser, electron beam, or plasma jet. The print head then selectively applies energy to the powder or wire to melt and deposit it onto the build platform.

3. Photopolymers

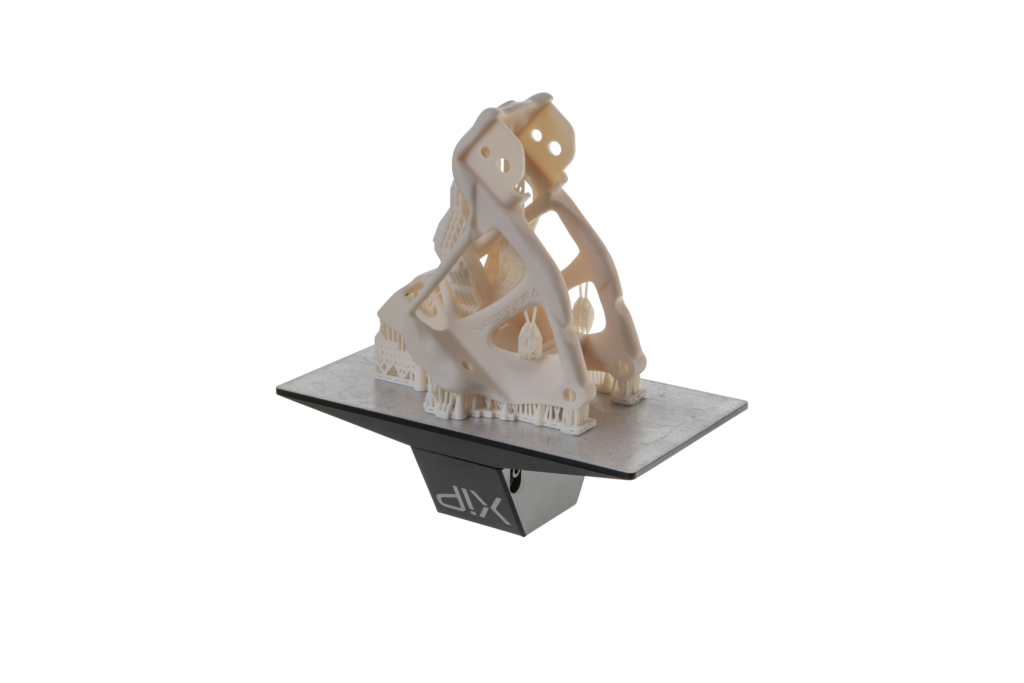

Resin 3D printing capabilities with Nexa3D’s XiP.

Photopolymers, or thermosets, are polymer materials whose qualities and properties change when exposed to a source light. Light causes a reaction that changes the photopolymer’s structure and alters its mechanical and chemical buildup.

Photopolymers are more versatile than other materials and can create objects that adhere to different specifications. They’ve been used for various 3D printing processes, especially since the advent of Stereolithography (SLA) 3D technology. They’re well known for providing a great surface finish.

Photopolymers can be used in resin and filament 3D printers. Resins are typically made from a polymer, such as an acrylate, and are mixed with a photoinitiator. When exposed to light, the photoinitiator causes the resin to harden and become solid. Filaments are plastics formatted in a slender strands and melted to create a product’s desired shape.

3D Printing Technologies that Use Photopolymers/Thermosets

Photopolymers are frequently used in:

- SLA (Stereolithography): SLA 3D printing uses a laser to cure a photopolymer resin layer by layer. The laser beam is focused on a small spot on the surface of the resin to selectively cure the resin. The laser beam is moved across the surface of the resin according to a predefined path and the layer is cured layer by layer until the 3D model is completed.

- Digital Light Processing: DLP uses light to cure a photosensitive resin. It’s similar to SLA technology, but instead of using a laser, DLP uses an LCD screen or projector to display the images of each layer which then cures when exposed to light. The projector flashes an image of an entire cross-section, thereby printing a whole layer at once. This ensures faster printing speeds and represents a major upgrade from the traditional SLA 3D printers. However, its single projection source means that the image can become distorted, which can lead to uneven build quality.

- mSLA (Masked Stereolithography): mSLA produces prints with the best surface finish and is excellent for complex geometries s. This technology uses an LED light array as the energy source rather than a laser or a single projection point. This LED array projects light through an LCD panel, which masks the necessary pixels while printing and allows only the necessary pixels to pass light. As a result, curing occurs only in the unmasked section.

- PolyJet: This process uses powdered photopolymer resins. These resins are jetted onto a build platform, layer by layer, and then cured with light to create a 3D object.

The Nexa3D printers use a patented mSLA variant technology, Lubricant Sublayer Photo-curing (LSPc), that combines a light array and collimated optical lens layer to ensure light uniformity at an ultrafast speed. Its patented self-lubricating Everlast 2 membrane eliminates the forces between the parts being printed, therefore enabling fast print speed without sacrificing the print quality or surface finish.

Getting the most out of our ultrafast LSPc technology is enabled by a broad range of fully validated resin materials, which are formulated to provide unprecedented print speed as well as part characteristics required for optimal mechanical performance.

Want to experience this technology for yourself?

4. Composites

Composite materials combine two or more different materials to create a new material with improved properties. Composite materials can produce parts with enhanced strength, stiffness, or thermal and electrical conductivity.

There are several composite materials available. Some include:

- Carbon fiber: Carbon fiber is robust and stiff, making it ideal for parts that must withstand high loads. Carbon fiber is also very lightweight, making it suitable for applications where weight is critical, especially in engineering.

- Kevlar: This is a relatively new composite material known for its high strength, toughness, and heat resistance. It’s used in making bulletproof vests, cycle tires, and other end-use parts.

- Fiberglass: Like carbon and kevlar, fiberglass is known for its high strength and stiffness. It can be combined with plastic and other materials to create sturdier, but flexible, parts.

3D Printing Technologies that Use Composite Materials

Here are some 3D printing methods that use composites:

- FDM: Composites are very common in the FDM 3D printing space as base thermoplastics can be easily mixed with composite materials. One of the advantages of FDM is that it can be used to print composite materials with a high degree of accuracy. However, the print quality is lower than in other techniques.

- SLS: In SLS 3D printing, builders use nylon as a common material for composite SLS powders. The process is similar to FDM but uses a laser to sinter (i.e. fuse) materials together. This allows for printing complex shapes and structures that would be difficult or impossible to print with FDM. Common composite materials for SLS include nylons with carbon fiber, mineral fiber, aluminum, or glass bead fills.

5. Powders

Powder-based 3D printing material. Image Credit: 3D printing industry.

Powders are somewhat of a 3D printing material subcategory since they are typically made of metals, thermoplastics, or ceramics. The 3D printer melts the powder by melting or spraying a liquid binder evenly across the build platform until the desired thickness is achieved.

The most common powder materials used for 3D printing are:

- Polyamides: Polyamide nylons are strong and durable. They allow for a high level of detail and are often used for joints and interlocking parts. For example, the PA11 and PA12 nylons have strong chemical resistance and excellent resolution.

- Polypropylene: Polypropylene is a thermoplastic polymer made from a combination of propylene monomers. It’s a semi-rigid and lightweight material that offers solid heat and impact resistance, but it has a slippery surface, which can make it hard to handle.

- TPU: Thermoplastic polyurethane is a varied polymer that combines the properties of both thermoplastics and rubbers. It’s s ideal for end-use parts, functional prototypes, concept models, and custom components.

3D Printing Technologies that Use Powders

Here are some 3D printing technologies that can use powders:

- Powder Bed Fusion

- Multi Jet Fusion (MJF): MJF is a powder-based 3D printing technology that uses multiple jets to deposit tiny droplets of liquid onto a powder bed. The droplets fuse the powder particles, layer by layer, to create a 3D object.

3D Printing Materials by 3D Printer Technology

Now, we’ll split up materials based on the 3D printing method.

1. SLA 3D Printing

In SLA 3D printing, a laser is used to cure photopolymer resin layer by layer until the design is created. SLA 3D printers often use photopolymer resins.

2. mSLA 3D Printing

mSLA 3D printers are resin 3D printers, which means there are numerous resin materials available to suit your specific purpose or application.

All top brands developing resin 3D printing technologies also have their own materials ecosystem. For example, Nexa3D provides a wide variety of resins for its mSLA 3D printer to meet performance requirements including PP-Like, ABS-Like, and engineering-grade functional materials, as well as materials designed for the manufacture of high-temperature components.

Nexa3D is one of the companies that supports an open materials program. Its open materials platform allows users to use proprietary materials developed and validated by partners or third-party manufacturers, as well as materials developed and validated by users themselves.

Learn more in Nexa3D’s ultimate 3D material printing guide.

3. FDM 3D Printing

FDM or FFF printers use thermoplastic filaments to print objects. Some filaments include:

- PLA

- ABS

- PETG

- Nylon

4. SLS 3D Printing

Thermoplastic materials used by Nexa3D’s QLS 820

Selective laser sintering primarily uses nylon, polypropylene, TPU, and PEKK materials.

However, SLS 3D printers like the Nexa3D QLS 820 can 3D print with other materials. A wide-use temperature range, inert processing atmosphere, and open-source platform mean it can print with PA12, PA11, and Polypropylene, as well as aluminum, glass, and fiber-filled nylon options.

3D Printing Material FAQs

What do 3D printing materials cost?

3D printing material pricing varies. The price of plastic filaments, for example, can range from $10 to $100 per kilogram, with the majority falling in the $20 to $50 per kilogram range.

The price of resins can range from $30 to $500 per liter, with most resins falling somewhere in the $50 to $200 per liter range. However, printing with resin allows for higher-quality prints at faster speeds, they’re well worth the investment.

Metal 3D printing can be one of the most expensive forms of 3D printing, with materials ranging from $400 per kg of stainless steel and over $800 per kg of titanium.

What is the most common 3D printing material?

The most common 3D printing material is plastic. Plastic material comes in different formats including resins and filaments.

What is the strongest 3D printing material?

Strong is a very relative term when it comes to material performance. A 3D printed materials’ strength varies by impact resistance, tensile strength, tensile modulus, and more.

For example, the thermoplastic polycarbonate is known for its incredible tensile strength. It can be a very rigid, high-modulus material for 3D printing–but that also means it can be brittle with a low-impact resistance. TPU has very low tensile strength, but its flexibility offers higher levels of impact strength, which means it can bend much further or absorb more impact without breaking.

Most high-performance polymers can offer a solid combination of both impact strength and tensile strength.

What is the best 3D printing material?

The best 3D printing material will depend on the end product and 3D printing technology used. However, photopolymer resins are increasingly popular choices thanks to their high-quality surface finishes, better accuracy, and greater precision than other materials.

These resins support the ultrafast production of functional prototypes and manufacturing components through professional 3D printers like Nexa3D’s XiP and NXE Pro series.

Ready to experience the capabilities of these 3D printing materials in real life?

Want to keep learning about 3D printing materials?

Download our latest 3D printing material guide for an even deeper review of the most popular 3D printing materials in 2023.