- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

For decades, companies have been utilizing mass customization for end products. While this allows them to use standardized processes and machinery to produce identical products in large quantities, it can be difficult to adapt quickly to changes in customer demand or market trends.

As manufacturers and brands move away from mass production, 3D printing is gaining traction as the best technology to use for custom manufacturing. 3D printing provides the ability to make very complex products accurately without costly tooling investments or setup fees.

This guide will explain custom manufacturing and production, how 3D printing technology can improve the process, and successful custom manufacturing created by 3D printing.

What is mass customization and manufacturing?

Mass customization and manufacturing is the process of designing, engineering, and creating products that meet a customer’s unique needs and specifications. Several industries are adopting custom production and manufacturing industries because customers are looking for products that aren’t available off the shelf.

For example, in jewelry making, custom production allows customers to design their own pieces that are unique and tailored to their tastes. Similarly, in automotive manufacturing, custom production enables companies to produce cars with individualized features, such as body kits and upholstery designs, for a more personalized driving experience.

Mass production vs. Mass customization

Unlike mass customization, mass production involves producing large quantities of identical products using standardized processes and equipment. It’s the process of producing identical products in large quantities using automated machinery, and it often requires costly investments in tooling and setup fees. Mass production is typically used for high-volume products such as consumer electronics, appliances, and other mass-market items.

Custom production focuses on producing unique products that meet the needs of individual customers or applications. It involves a more flexible approach to manufacturing and prioritizes customer satisfaction, even if it means sacrificing some efficiency.

Challenges of mass customization and custom production

Mass customization can be a complex and expensive process if you’re not using the right technology.

Design variability

When producing standardized products through mass production, manufacturers can use the same design for each product, which reduces costs and increases efficiency. In contrast, custom production requires manufacturers to create unique designs for each product they produce, which can be challenging and time-consuming.

Furthermore, design variability can also create challenges for supply chain management. With each product being unique, manufacturers may need to source different materials and components for each product, which can create inefficiencies and increase costs.

Efficiency

Custom production often requires a trade-off between efficiency and quality. Mass production is designed to be efficient by producing large quantities of identical products quickly and at a low cost. Custom production typically focuses on quality over quantity and customization over speed.

Mass customization requires more design, engineering, and quality control than mass production, which can also reduce efficiency. Also, with each product being unique, it can be challenging for the manufacturers to maintain consistent quality across multiple products. This need for quality control can further increase production time and costs, which can impact the overall efficiency of the custom production process.

Limited scalability, complexity, and lengthy lead times can also reduce the efficiency of custom production. Mass production relies on automation, making it easier to scale up quickly and maintain consistent quality across products. In contrast, custom production could require manual processes that are harder to scale.

How to Use 3D Printing for Custom Production and Mass Customization

Using additive manufacturing technology can mitigate the challenges that come with custom manufacturing. The best 3D printers can quickly and accurately create complex geometries with high precision.

With greater flexibility, scalability, and accuracy, 3D printing can be used for a wide range of custom products.

Molds

Rapid tooling for injection molding can be used to create intricate shapes quickly and with high precision. Traditional mold-making techniques involve creating a physical mold by carving or machining a block of material. This process can be time-consuming and expensive, especially with the need to create multiple iterations of a mold.

With 3D printing, manufacturers can easily modify the design of the mold to meet specific requirements, such as adding or removing features, changing the size, adjusting the shape, and increasing production efficiency.

Casts

3D printing can also produce molds for casting quickly and more affordably than with traditional manufacturing processes. This process involves printing a part with a 3D printer and casting it with a liquid metal or other materials, such as wax or plastic.

Manufacturers can quickly produce complex shapes that are otherwise impossible to cast without expensive tooling, specialized equipment, and lots of time.

End-Products

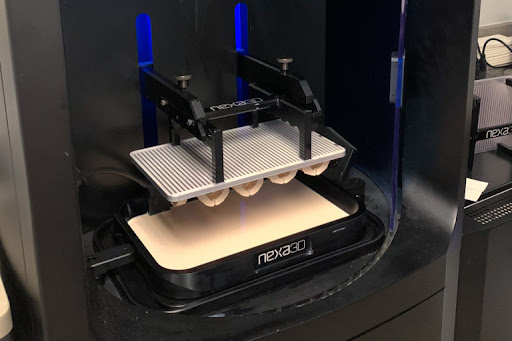

3D printing can produce end-products that require intricate geometries and high-quality surface finishes, especially with mSLA 3D printers. Manufacturers use mSLA 3D printers to mask the necessary pixels while printing and allow only the necessary pixels to pass light. The end result is a distortion-free product with better surface finishes.

Producing with the mSLA technology is even better when manufacturers use advanced technology like the Nexa3D’s Lubricant Sublayer Photo-curing (LSPc®). This proprietary 3D printing technology combines a UV light array and LSPc Optical lens layer to ensure light uniformity in this process, which is essential for edge-to-edge performance with no distortions.

Mass Customization & Custom Production Examples

Custom production is widely used in many industries, including automotive, aerospace, and medical. Here are some examples of custom manufacturing:

Dental Products

Dental products, from dentures to aligners, may be the most ubiquitous case of mass customization on the market today. They must perfectly fit one’s anatomy–requiring precise, accurate, and high-quality molds safe for humans to wear. Therefore, the dental industry has turned to 3D printing to produce custom dentures, aligners, models, splints, impression trays, occlusal night guards, and more.

A great example is Key Dental Technologies, a full digital laboratory supplying orthodontic clear aligners to MyOrthodontist, the largest network of family orthodontic practices in North Carolina.

In addition to offering a full range of braces and retainers to adults and teens, MyOrthodontist offers clear aligners–most notably the FDA approved and patent-pending clear aligner system, MyClearALIGN!, that was made possible by the NXD 200.

The NXD 200 allows them to produce 20 models every thirty minutes–but with incredible accuracy, quality, and fine details that other 3D printers weren’t able to achieve.

Prosthetics

Medical professionals have been creating custom prosthetics with 3D printing technology since 2011. Medical-grade, biocompatible 3D printing materials can copy the actual anatomy of the human body and provide users the ability to walk, share high fives, and give a thumbs up.

Charity LifeNabled, which provides free clinics and prosthetics in northern Guatemala, created a fully digital process to produce customized 3D prosthetic sockets with flexible inner liners. The team generated the prosthetic socket designs digitally and 3D printed them with TPU materials. The new digital process cut the team’s production time from more than three days to several hours.

Consumer Products

PepsiCo uses the NXE 400 3D printer with xPEEK147 material for various aspects of bottle development. The company uses 3D printing technology to produce more than 10,000 bottles and compress its prototype tooling development time from 4 weeks to 48 hours.

Applied Rapid Technologies (ART) is another company benefitting from 3D-printing technology for casting. After years of facing challenges with Urethane casting parts, ART now uses the NXE 400Pro to print over 25 pieces of custom mold parts, jigs, and fixtures in an hour. This allows the firm to deliver mold and jig parts on-demand and with superior quality in a fraction of the time it would take to produce them using traditional methods.

Transportation & Automotive Industry

The transportation industry is one of the largest users of 3D printing in custom production. Companies in this sector are using 3D-printed components to produce intricate components that are lightweight, durable, and cost-effective. This reduces production costs and lead times significantly.

For instance, manufacturers in the automotive industry use Nexa3D high-quality 3D printers for rapid prototyping and custom product development. These 3D printers offer superior accuracy and rapidly produce end-products with smooth surfaces. This allows them to quickly create custom parts for cars and other vehicles, making it easier for them to meet customer demands promptly.

Also, Alstom, one of the largest railway companies, manufactures high-speed train parts using 3D printing technology. The company uses NXE 400Pro Industrial 3D Printer and xABS3843 Resin to produce components for its trains, including interior fittings and exterior decorative pieces. This allows them to quickly produce custom parts for their trains without incurring additional costs associated with tooling and other intermediate steps in the production process.

Consumer Products

Nexa3D printer installed at Murtfeldt AS’ plant in Tübingen, Germany, near Stuttgart

Companies in this sector use 3D printing technology to produce complex, customized components with high precision and superior surface finishes. This helps them reduce costs and lead times associated with production while still producing quality consumer products.

Murtfeldt Additive Solutions GmbH is a perfect example of this. The company uses NXE 400Pro and xABS materials to quickly produce critical electrical connectors like battery connectors, USB cables, and Ethernet plugs. The company now achieves speed and accuracy that is hard to match with traditional methods, enabling them to produce complex electrical parts for consumer products.

Benefits of Using 3D Printing for Custom Production and Manufacturing

The advantages of 3D printing for custom production and manufacturing are numerous. Here are some key benefits:

Flexibility

3D printing offers manufacturers great flexibility when it comes to product design. They can quickly and easily customize the components to meet customer demands with minimal effort.

Cost Optimization

Custom production using 3D printing requires less time and labor, reducing costs compared to traditional methods. This allows manufacturers to save both time and money when producing customized parts. The biggest cost savings is actually associated with not having to manufacture a minimum order quantity in order to get the price down, thereby not needing to carry a lot of inventory. Mass customization requires lower quantities and those lower quantities are not cost-effective to be produced in mass.

Speed

The speed of 3D printing allows manufacturers to quickly and efficiently produce custom components with high accuracy. This reduces lead times significantly, enabling them to meet customer demands promptly.

Use the Best 3D Printers for Custom Production and Mass Customization

3D printing technology allows production to move from days or weeks of development time to hours or minutes. Businesses can faster design cycles, a quicker time to market, and more flexibility–all while customizing products to their customers’ needs.

Nexa3D is the leading provider of 3D printing solutions for the custom production and manufacturing industry. With an array of ultrafast 3D printers and superior Lubricant Sublayer Photo-curing (LSPc®) 3D printing technology, manufacturers can produce high-quality components and end-use products in a fraction of the time compared to other popular 3D printers.

Request a free sample part today and revolutionize your custom production process with Nexa3D.