- Everything you need to know about ABS 3D printing - March 9, 2023

- How a New Generation of 3D Printers is Accelerating the NPD Process - November 16, 2022

- Buyer’s Guide to an Industrial 3D Printer - October 31, 2022

There are literally hundreds of desktop 3D printers on the market today. Many are cheap enough for the casual hobbyist, but what about professional designers and engineers? Here are the things to look for in professional desktop 3D printers.

The world’s first commercial computers were huge, bulky affairs that cost many millions of dollars and filled entire rooms. Back then, data processing jobs were scheduled well in advance and people often had to wait days for the results. Fortunately, those seemingly ancient times are well behind us. Desktop computers, laptops, and workstations are now ubiquitous, and people everywhere are free to work on product designs or create the next greatest piece of digital art at will. The result is greater creativity, shorter development cycles, and a workforce unhampered by hardware limitations.

Why buy?

So it is with 3D printers. Whether it’s rocket scientists at NASA or hobbyists in their home workshops, people are no longer satisfied with outsourcing their latest brainchild to a service bureau and then waiting days for their product to arrive. They want to touch and feel product designs now and see how the components fit together. In many cases, they’ll want to put these parts to work—in functional testing, for instance, or as a stopgap measure while waiting for an OEM replacement part to arrive—but it could just as well be for an end-use, permanent application. Whatever the need, 3D printing with its growing accuracy and material options will often fill it handsomely.

But what’s wrong with outsourcing? It’s quite easy to transmit designs electronically to a 3D printing service bureau—simply upload the file, enter your credit card information, and a few days later, your 3D-printed parts arrive. Not so fast, however. The seemingly endless wait between iterations can be quite stifling to a fast-moving design team. And depending on the company and its approval process, there could be any number of hoops to jump through when outsourcing. So while there might be some fine reasons to use an external provider, the fact remains that 3D printing from the convenience and accessibility of a desktop 3D printer is almost always preferable. No waiting, no added expense, and the freedom to iterate at will.

So which 3D printer is right for your needs? Great question. Shopping for one means wading through a confusing universe of choices, from laser-based, metal powder bed printers that cost upwards of a million dollars to hobby-level machines available online for the price of a meal at a nice restaurant. In fact, seven distinct 3D printer technologies exist, each with its strengths and weaknesses, dedicated adherents, and no small number of equipment suppliers. Again, which printer should you buy?

This article will provide guidance on that very important question. We won’t discuss plastic and metal powder bed systems–for starters, they’re too expensive for personal use, and they certainly don’t fit on a desktop. Nor will we delve too deeply into the many flavors of hobby machines, except to offer the age-old argument “you get what you pay for.” That’s not to say these ultra-low-cost 3D printers don’t have their place—they do, but it’s more likely the printing of plastic chess pieces and action hero figurines, not functional components or precision prototypes of product designs.

The two types of professional desktop 3D printers

Professional desktop 3D printers fall into one of two categories, fused deposition modeling (FDM) 3D printers and those that use resin-based vat polymerization. The latter includes stereolithography (SLA), direct light processing (DLP), masked stereolithography (mSLA) and its subcategory lubricant sublayer photocuring (LSPc), each of which uses a programmable light source to selectively cure part layers in a vat of photoreactive resin. More on this shortly.

Before pulling back the covers on each of these to reveal its strengths and weaknesses, it’s important to note that not all such 3D printers are desktop 3D printers. So-called “large format” FDM 3D printers, some of which boast build volumes of a cubic yard or more, are readily available. And standalone, industrial-grade SLA 3D printers have been a staple of the 3D printing industry since stereolithography’s invention nearly four decades ago. As you will see, this older laser-based technology is gradually losing ground to faster, more affordable mSLA 3D printers, even though proponents will counter that lasers provide higher resolution (albeit at slower speeds). Regardless, the remainder of this discussion will focus on smaller, professional-grade 3D printers costing less than $10,000 and suitable for an office or possibly a home environment.

FDM 3D Printers

Legend has it that when Scott Crump of Stratasys invented fused deposition modeling, he used a hot glue gun to deposit thin layers of polyethylene mixed with candle wax, thus building the world’s first 3D-printed toy frog. Today’s FDM 3D printers employ a similar arrangement, feeding plastic filament from a spool through a heated deposition head onto the platform below. Servo motors or, on some machines, lower-cost stepper motors are used to drive the head through its programmed motions around and within each layer’s periphery, building the part upward as it goes.

FDM 3D printers build parts from weed whacker-like reels of thermoplastics. A wide variety of materials is available, some of the most common being ABS (acrylonitrile butadiene styrene), PLA (polylactic acid), and PET (polyethylene terephthalate). Many of these require a heated bed or heated chambers to minimize warpage and assure sufficient intra-layer adhesion, while others (PEEK – polyether ether ketone – is one) can only be printed on machines with high-temperature deposition heads. Worse, some of these materials emit harmful fumes or ultrafine particulate matter when heated, so be sure to use them in a well-ventilated room. Some also absorb humidity from the environment, and should be stored in a cool, dry place.

Feedstock considerations aside, FDM 3D printers are a popular choice for many desktop 3D printing applications. Higher-end machines in this category typically have an enclosed chamber and environmental controls to alleviate the problems just mentioned. Most have wireless connectivity, reinforced feeder mechanisms and high-temperature nozzles for use with engineering-grade polymers, and auto-leveling systems to assure that the bed is perfectly horizontal when printing. Some FDM 3D printers even have dual extruders that allow the user to print two materials—different color plastics, for example, or one extruder for support material and the other for the workpiece.

We’ll discuss the pros and cons of these and other systems shortly, but for now, know that FDM 3D printers are a viable option for many prototype parts, jigs and fixtures, and even some end-use components (provided a suitable material is used). However, buyers should be aware that FDM 3D printers print parts with significantly lower surface quality and accuracy than competing desktop 3D printers, making secondary finishing or even machining a must for critical features and cosmetic surfaces.

Resin 3D Printers

Then there’s resin-based vat polymerization. Compared to the FDM 3D printers, resin-based 3D printing provides exceptional detail, smooth part finishes, and fine resolution (which usually translates to higher part accuracy). As you’ll see, the newer vat polymerization technologies are also much faster than FDM 3D printers–in some cases,dramatically so. In addition, chemical companies are laser-focused on resin development, giving users a wealth of engineering-grade materials that perform well even under extreme conditions, with more coming available each day.

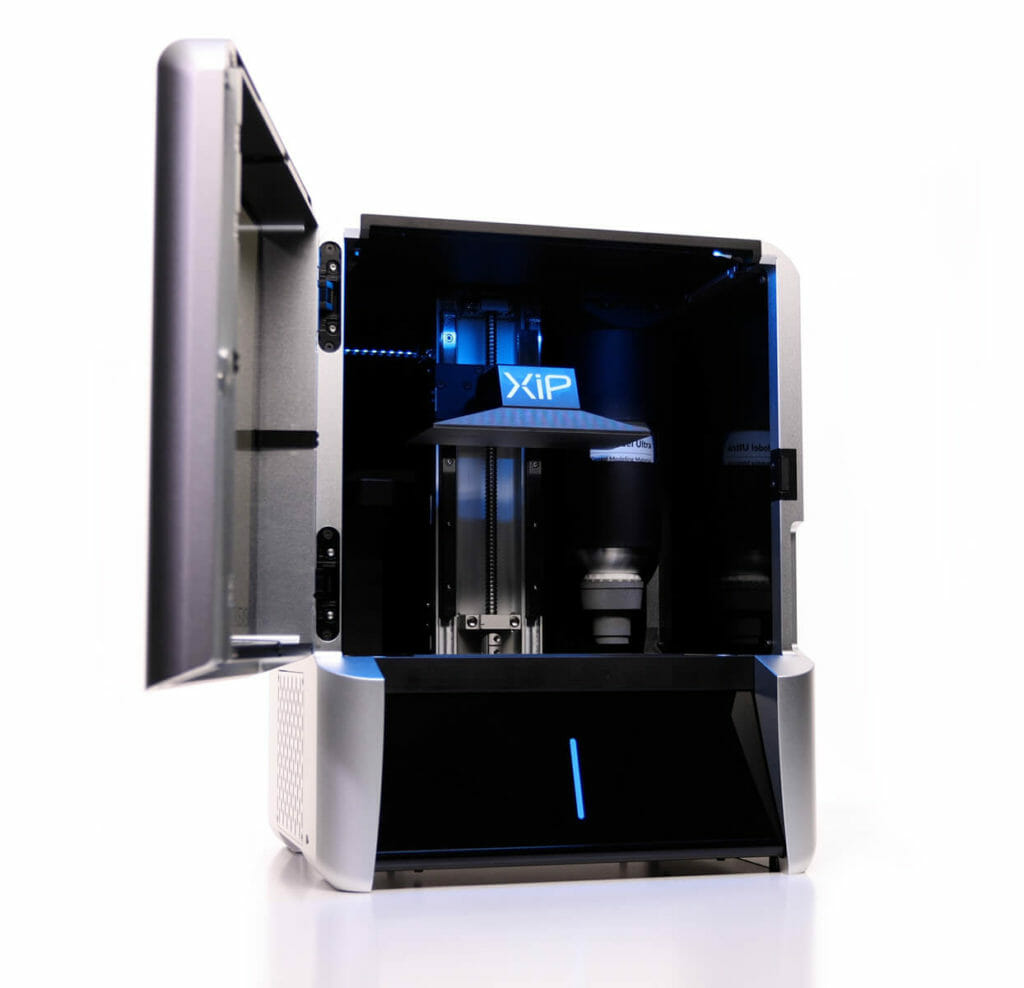

As noted earlier, four distinct technologies exist—SLA 3D printers, DLP 3D printers, mSLA 3D printers, and LSPc 3D printers—the last being Nexa3D‘s proprietary mSLA process. All are covered in great detail in our Definitive Guide to Ultrafast 3D Printing, so there’s no need to get into the weeds again except to say that, if you determine that vat polymerization is indeed the best solution to your or your company’s desktop 3D printing needs, we encourage you to review the guide and take a hard look at Nexa3D’s XiP desktop 3D printer offering. It falls squarely into the “small but capable” category and addresses the shortcomings found in competing vat polymerization technologies.

With that in mind, here’s a Reader’s Digest version of the various vat polymerization technologies. As the name suggests, all use a tank or vat of photoreactive resin and a light source to cure it. What’s different is how that light is generated, where it’s aimed, and how the system introduces fresh resin during the printing process.

- SLA: For instance, SLA 3D printers use a laser beam and a set of programmable mirrors to aim it, painstakingly tracing every square millimeter of each part layer and curing the resin as it passes. Standalone industrial SLA 3D printers utilize an elevator and blade arrangement to lower the workpiece and draw resin across its top upon completion of each layer, while desktop SLA 3D printers direct the laser beam through a transparent membrane or “window” in the tank’s bottom; after each layer, the build platform lifts and fresh resin is drawn into the void between membrane and workpiece.

- DLP: This bottom-up arrangement eliminates the need for bulky tanks, which is why it’s not common to practically all resin-based desktop printers. Unfortunately, it doesn’t make SLA 3D printers with their tiny laser beams rastering any faster, which is why manufacturers of DLP 3D printers project an entire image of each part layer at once onto the workpiece’s underside, curing it instantly. This approach is clearly much faster, and even though DLP 3D printers are slightly less accurate and uniform than SLA 3D printers, we might end the story here but for one factor: the chips used to generate the image are proprietary, raising costs, limiting their usage, and dampening further development.

- mSLA: Meet DLP’s alternative, LCD and LED, the same technology used in gazillions of television sets, computer monitors, and—you guessed it—mSLA 3D printers, Nexa3D’s included. Here, a high-resolution LCD generating a “mask” of the layer image (the small “m” in mSLA) sits between an LED array (responsible for the photocuring light) and the transparent membrane in the tank’s bottom. Like DLP 3D printers, this cures an entire layer in one go, but because there are fewer power limitations as well as lower image distortion, mSLA 3D printers provide faster build speeds and higher part quality.

- LSPc: The final piece of this desktop 3D printing puzzle comes from LSPc, which eliminates several well-known problems with resin’s tendency to “stick” to the membrane and the resultant decrease in replenishment speed, not to mention maintenance and longevity concerns. Here again, check out our Definitive Guide to Ultrafast 3D Printing guide for the nitty gritty on all this, but for now, it’s time to circle back around to the material discussion.

Liking polymers

Assuming the printer is designed to handle them, FDM 3D printers win the material availability contest hands down. Yes, ABS and PLA are by far the most widely used, but owners of desktop FDM 3D printers can also find filaments impregnated with everything from wood or metal particles to carbon fiber, ceramic, and much more.

There are some caveats. As noted earlier, the printer must be equipped with the correct nozzle and dispensing mechanism, not to mention the necessary heat rating. And before you get too excited about the prospect of custom 3D-printed croquet balls, though, please recognize that these bamboo and birch filaments are still made of polymer (most likely PLA), but contain enough wood particles to give the finished product a wooden feel and appearance.

As far as metal goes, please note that FDM-printed bronze or stainless steel parts don’t become fully solid until sintered in a furnace, and even then, they don’t approach the structural integrity of those made on a metal powder bed printer. Still, such material options open the door to projects that might otherwise require outsourcing to a service bureau.

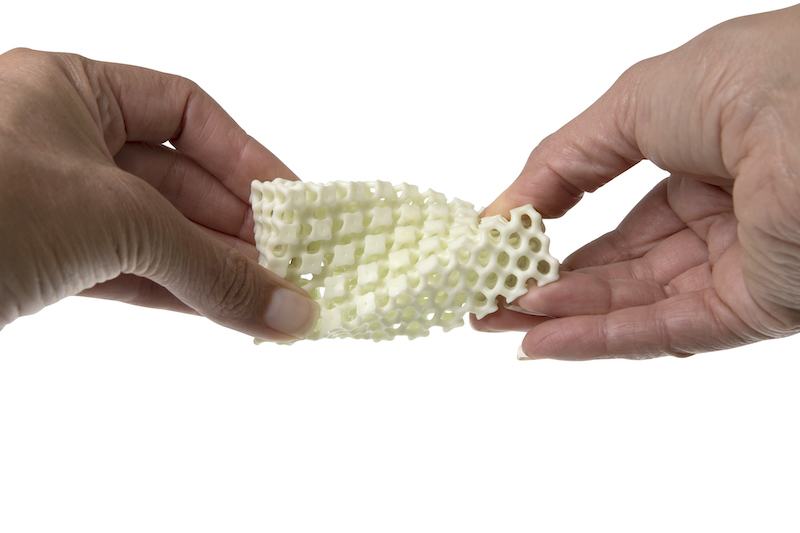

And yet, there’s certainly no shortage of resins for vat polymerization printers. A glance at Nexa3D’s Material Selection Guide shows 22 different options, starting with tough, durable xABS, rubber-like xFLEX475, and xPEEK147, a heat-resistant engineering grade material similar to PEEK. Each of these is part of an open material platform, opening the door to further material development. Other companies have similar offerings, some open, others not, allowing resin-based desktop 3D printer operators to produce optically clear camera covers, soft, squishy tennis shoe soles, weatherproof automobile components, and countless other items.

Here’s one final consideration on the differences between thermoplastic filaments found in FDM 3D printers and the photoreactive resins used in vat polymerization 3D printers. Note the qualifiers “similar to” and “like” just now describing some of our materials. You’ll find similar verbiage elsewhere. That’s because the resins used in any SLA 3D printers, DLP 3D printers, or mSLA 3D printers are not thermoplastics per se but rather mimic (and often exceed) their properties when fully cured.

The reason is simple: today’s photoreactive resins were designed for use in 3D printers and have been tailored to deliver specific properties. Not so with thermoplastics filaments, which are the same materials used to make plastic rod, sheet, and injection molding feedstock, albeit in different forms. There’s nothing wrong with this; just be aware that you won’t find “PET” or “PLA” listed on Nexa3D’s nor any other stereolithography-based printer manufacturer’s website, and that what’s essential are tensile strength, flexural modulus, hardness, and other properties that will affect the final product’s performance and durability.

Of size and productivity

Materials and 3D printer functionality aside, those shopping for a professional desktop 3D printer have plenty more to consider, starting with part quality. As suggested earlier, vat polymerization wins the prize in terms of precision and surface finish. There’s little stair stepping, the parts are less prone to delamination and warping, and there are never any surface defects caused by having to stop mid-build to replace a reel. That’s not to say that parts made with FDM 3D printers can’t be made pretty, but doing so will require additional effort such as sanding and polishing, which will have a negative effect on part accuracy.

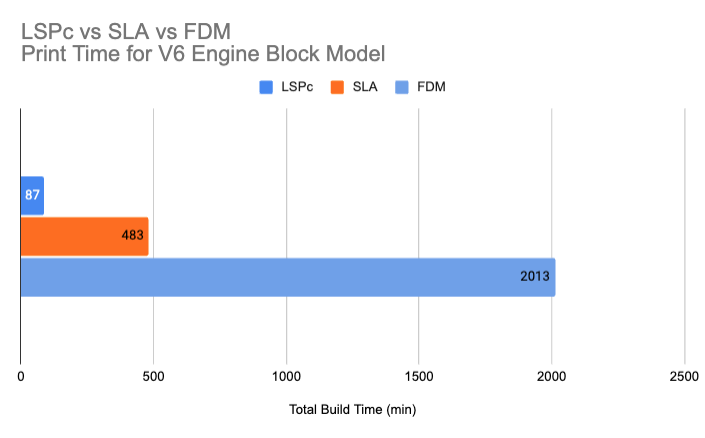

It will also take time. Secondary operations are a fact of life with all 3D printers, something we’ll explore further in a moment, but for now, let’s segue to productivity. SLA 3D printers are generally faster than FDM 3D printers. DLP 3D and mSLA 3D printers are faster still, and LSPc technology (a subset of mSLA) blows the doors off all competition with build speeds up to 20X that of other vat polymerization machines. Refer back to the guide for additional details.

Part size is another consideration. If the build software supports it, FDM 3D printers and SLA 3D printers allow users to fill the entire build chamber with parts, stacking them one atop the other as needed. And if parts are too large for the platform, CAD software can be used to “split” parts into smaller pieces before printing, then assemble or glue them together afterward. This approach, however, takes time and effort on both sides of the build process, which is why it’s always a good idea for those who need it to go for the largest build volume they can buy.

That said, anyone looking to “build big” might be tempted to spend their money on one of the gantry-style, enclosure-less FDM 3D printers. These typically provide the greatest bang for the buck where part size is the primary concern, but remember what was said earlier about harmful fumes and be sure to use such printers in a well-ventilated area. Nor will these large, low-cost machines deliver the same part accuracy as one designed for commercial use.

Built to last

That brings up reliability. For occasional printing or where budget rules the decision-making process, there might be no choice but to start with a hobby-grade machine, whatever its limitations. For everyone else, it’s crucial to invest in a high-quality professional desktop 3D printer that will provide the resolution, accuracy, layer thickness, and print speed needed to be successful. Ask about the warranty, request some sample parts, talk to others about their support experience, and be sure to check out training options. It’s no good buying a printer you don’t know how to operate, or that breaks down within the first year.

Also, take a look at post-processing requirements. FDM 3D printers have a slight edge here, particularly for conceptual models, jigs and fixtures, and replacement parts where part precision and appearance are unimportant—once you’ve broken away the support materials and removed any rough edges, these and other parts can be put to immediate use or brought to the workbench for additional smoothing.

Not so with resin-based printers. Here, parts must first be washed to remove any uncured material, then placed in a UV-light chamber for a few minutes (depending on part size) until fully cured. And yes, support removal is also required. Regardless, Nexa3D has made this process very fast, easy, and environmentally friendly with its xWASH and xCURE post-processing solutions. Other manufacturers have their own platforms, which you should be sure to investigate when comparing systems.

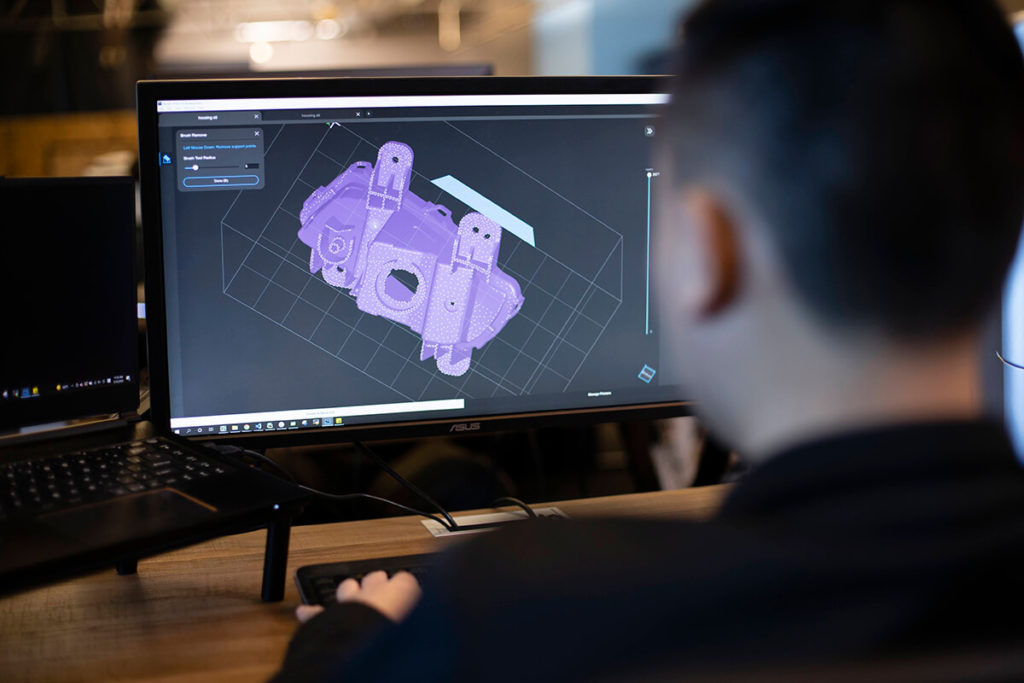

Finally, ask about the build software, an often overlooked aspect of 3D printing critical to throughput but often lacking in desktop 3D printers. For instance, the software should provide automated part orientation and lattice generation. It should detect out-of-bounds conditions, support the Z-stacking needed to fill the build chamber, and provide remote management and print view capabilities. It should also be easy to use yet powerful, with advanced tools like mesh fixing and scaling capabilities.

It’s certainly a big decision, especially for anyone investing in a 3D printer for commercial or industrial uses. Whatever your reasons, we encourage you to do your homework and check all the boxes before signing on the dotted line. By all means take a hard look at equipment cost, but more importantly, evaluate the total cost of ownership. Yes, resin-based printers are typically more expensive up front than FDM 3D printers, but almost always provide more value to professional users. Vat polymerization delivers better part quality, smoother finishes and finer detail, greater throughput and build chamber utilization (especially mSLA 3D printers). Couple that with a streamlined workflow and less post-build finishing effort and you’ll soon come to realize that resin beats reels, hands down.