- Metal 3D Printing Guide: What It Is & How It Works [2024] - February 5, 2024

- Metal Injection Molding: What It Is & Top Alternatives [2024] - January 11, 2024

- 11 Fastest 3D Printers on the Market (Industrial and Desktop) [2023] - December 11, 2023

Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are two prominent 3D printing technologies widely used across industries.

Though similar in some aspects, MJF and SLS employ distinct methods for fusing materials–and have unique advantages and limitations. Understanding the differences between these two techniques is necessary to make an informed decision between 3D printers.

This comprehensive guide will explore how MFJ and SLS 3D printing works, their pros and cons, and the top 3D printers available. We’ll also conduct a head-to-head comparison between MJF vs SLS by evaluating them on various parameters, including workflows, materials used, surface finish quality, mechanical properties, dimensional accuracy, printer costs, print speeds, production throughput, and sustainability.

SLS 3D Printing

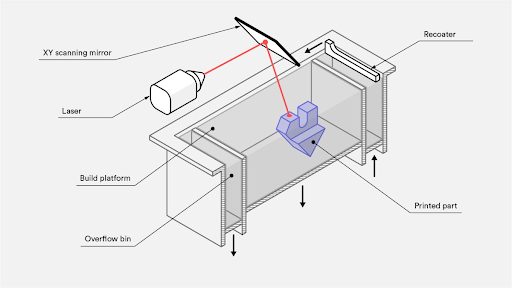

Selective Laser Sintering (SLS) is a 3D printing technology that utilizes a laser beam to melt together small particles of polymer powder and create a solid object based on a 3D model.

How it Works

In SLS, a high-power laser selectively melts small particles of polymer powder. The laser traces the object’s cross-sectional area on a powder bed, melting the particles together to form a solid structure.

The bed is then lowered, a new layer of powder is spread across the top, and the process repeats until the entire object is formed. SLS doesn’t require support structures since the unsintered powder provides ample support for features like overhangs.

The SLS process involves these key steps:

- Spreading a thin layer of powder material onto the build platform

- Utilizing a high-power laser, often CO2 or fiber lasers, to trace the object’s cross-section, selectively melting the small particles of polymer powder

- After the layer is sintered, the build platform is lowered to make room for the next layer

- Applying a fresh layer of powder material on top of the previous layer

- Repeating the sintering and layering process until the entire object is formed

- Allowing the build chamber to cool down

- Removing the objects from the powder cake and cleaning off any excess powder.

- If necessary, post-processing the object to achieve the desired finish and mechanical properties

Pros

SLS 3D printing has carved out a niche in the 3D printing landscape, known for its ability to produce highly durable and complex geometries. While SLS shares some common ground with MJF, it also possesses its own set of distinct advantages.

Here are some of the pros of SLS 3D printing:

- Complex Geometries: SLS can produce intricate designs and complex geometries that are difficult to manufacture with other techniques.

- High Durability: Parts made with SLS are known for their strength and durability.

- No Support Structures Needed: SLS doesn’t require support structures, reducing material wastage and post-processing time.

- Material Variety: SLS is the most well-developed powder bed fusion process and can manufacture parts using various polymer materials

- Good Surface Finish: SLS achieves a relatively smooth surface finish, which post-processing can further improve.

Cons

Although SLS is a powerful 3D printing technology, it has limitations and challenges. These must be considered to decide whether SLS is the right fit for a given project. Here are some of the cons of SLS 3D printing:

- High Initial Costs: SLS printers and materials can be expensive, especially for industrial-grade machines.

- Powder Handling: Managing the powder can be complex and requires careful handling, including facility enhancements to mitigate powder contamination.

- Post-Processing: Parts may require additional post-processing steps for cleaning and achieving desired finishes.

However, selecting the right SLS 3D printer can mitigate many of these challenges. For instance, Nexa3D’s SLS 3D printers have user-friendly interfaces and features that streamline powder handling and post-processing, and they come with advanced technologies that speed up build times significantly.

With Nexa3D’s printers, the initial costs are competitive, and the long-term operational efficiency provides an outstanding return on investment. Finally, using high-quality materials in Nexa3D’s printers further ensures that the mechanical properties and finish of the printed parts meet the highest standards.

Learn more about Nexa3D SLS 3D printers.

When to Use SLS 3D Printing

SLS 3D printing is especially well-suited for projects demanding high strength, durability, and the ability to produce complex geometries without support structures. Its versatility in material choices makes it a popular option for various applications.

Here are a few scenarios where SLS excels:

- Prototyping: When developing prototypes, especially for parts with intricate designs or internal structures, SLS is an excellent choice.

- Production of End-Use Parts: For producing durable end-use parts, such as housings, brackets, or enclosures, SLS’s strength and material properties are highly advantageous.

- Customized Medical Devices: In the healthcare industry, SLS is often used to create customized medical devices and like custom orthotics and surgical guides that must fit precise specifications.

- Aerospace Components: The aerospace industry benefits from SLS’s ability to fabricate lightweight, strong, and complex parts that meet flame retardancy standards and can withstand the extreme conditions of aerospace applications.

- Art and Fashion: SLS is popular in the art and fashion industries for creating intricate designs, sculptures, jewelry, and accessories that would be difficult to manufacture through traditional methods.

- Small to Medium Production Runs: SLS is the technology of choice for cost-effective, small to medium production runs, as it doesn’t require molds or tooling and can produce multiple parts in a single build.

- Manufacturing with Diverse Materials: SLS flexibility in material choice can be invaluable for projects requiring various materials, from neat and composite nylons to polypropylene, TPUs, and even high temperature materials like PEEK. QLS printers can even manufacture metal parts in alloys like SS 17-4 and Titanium.

Read the ultimate guide to SLS 3D Printing

Best SLS 3D Printers

When it comes to SLS 3D printing, the choice of printer can significantly affect the quality, speed, and efficiency of production. Here are some of the best SLS 3D printers:

- Nexa3D QLS 820: With the highest part throughput in its class, the QLS 820 thermoplastic 3D printer is a quad laser system offering unprecedented production capabilities designed with automation and scalability. The QLS 820 takes 3D printing to a new level, producing up to 4x the throughput of traditional laser sintering 3D printers and other polymer powder bed technologies.

- Nexa3D QLS 230: QLS 230 is the most affordable open platform SLS 3D printer for industrial use. It provides a 24-hour cycle speed using a single 30 Watt CO2 laser to produce prototypes with robust mechanical and thermal properties.

- Nexa3D QLS 236: QLS 236 is an open platform SLS 3D printer with an unrivaled 21-hour cycle speed. It uses a single 60 Watt CO2 laser to produce prototypes and production parts with robust mechanical and thermal properties.

- Formlabs Fuse 1: Fuse 1 brings SLS technology to an affordable price point without sacrificing quality, making it ideal for small businesses and startups.

- EOS P 396: This industrial-grade machine is well-suited for high-volume manufacturing. With excellent precision and a wide range of compatible materials, it’s a staple in the aerospace, automotive, and medical industries.

- 3D Systems SLS 380: This printer offers an algorithm that helps manage thermal uniformity, material quality centers for powder management, compatibility with multiple materials, and integration with 3D Sprint software.

- EOS INTEGRA P450: Designed to bridge the gap between rapid prototyping and mass production through a scalable, module design, key features of the P450 3D printer include a broad material range, a heating chamber with eight independent heating zones, and a 120 watts CO2 laser.

Review all of Nexa3D’s SLS 3D printers.

MJF 3D Printing

Multi Jet Fusion (MJF) 3D printing has been promoted as a notable advancement in additive manufacturing. Developed by HP, MJF offers an alternative approach to prototyping and batch production, but it’s important to evaluate its capabilities.

How It Works

MJF 3D printing creates three-dimensional objects by applying a fusing agent to a bed of powder material, followed by detailing agents to somewhat control the fusing at the boundaries. The process is completed using an energy source (often an infrared light) to fuse the powder particles.

The MJF process involves:

- Laying down a thin layer of powder material across the build plate to act as a base for the object being printed

- Adding the first agent, a fusing agent, which is applied to the sections where the powder is to be fused

- Applying the second agent, which are detailing agents used to improve surface quality, add colors, or other aesthetic features.

- Fusing the particles using an energy source

- Repeating these steps layer by layer until the object is complete

Pros

MJF 3D printing over some advantages, including:

- Speed: MJF competes with other 3D printing technologies by fusing larger areas in one pass.

- Attempts at Precision: The use of detailing agents aims for sharp edges and details.

- Material Reusability: Unfused powder can partially be reused in MJF 3D printing (though there are some restrictions and recyclability is typically lower than the SLS process).

- Strength and Durability: The objects produced are typically strong and can be used for functional parts.

Cons

MJF has certain limitations and challenges that must not be overlooked. Acknowledging these limitations can provide a clearer perspective and can lead some manufacturers to choose alternative printing technologies like SLS as more efficient options.

- Cost: MJF printers often come with high initial investment.

- Limited Material Range: MJF mainly supports Nylon 12, Nylon 11, and Thermoplastic Polyurethane (TPU), which limits its applications.

- Excessive Post-Processing Requirements: MJF parts typically require elaborate post-processing to achieve an acceptable surface finish. After breakout and media blasting, parts are often dyed to give a uniform finish.

- Powder Management: Handling the powder is not only messy but demands caution.

MJF 3D Printing Use Cases

MJF 3D printing can be an option in various 3D applications. However, SLS 3D printers can also be used in any of the following cases:

- Rapid Prototyping: MJF’s speed and precision make it work for creating functional prototypes in a short amount of time.

- Production of Detailed Parts: When manufacturing parts with intricate details or complex geometries, MJF’s high-resolution printing capabilities can be advantageous.

- Customized Consumer Goods: MJF allows for levels of customization when producing consumer goods such as phone cases, fashion accessories, or household items.

- Automotive Components: In the automotive industry, MJF can be used for producing durable and lightweight parts such as brackets, fixtures, and interior components.

- Production Runs: MJF can be cost-effective for high-volume production since it can produce multiple parts in a single build with consistency and reliability.

Best MJF Printers

Here is a curated list of some of the top MJF 3D printers available for small and larger projects.

- HP Jet Fusion 580: Works for small- to medium-sized projects with color printing options.

- HP Jet Fusion 5200: Targets industrial-scale production but can also require substantial investment.

- HP Jet Fusion 4200: A good balance between the 5200 and 580, offering industrial capabilities at a more affordable price.

MJF vs SLS 3D Printing

While both MJF and SLS are powder-based 3D printing technologies, they have distinct characteristics, advantages, and limitations.

Workflows

MJF and SLS have different workflows. While MJF operates by applying fusing agents and heat, SLS uses a precise laser to melt powder layers. However, the laser technology in SLS allows for greater control and often results in better-defined parts. Additionally, SLS’s longer-standing history has led to more refined workflows.

Materials Used

MJF, predominantly focused on polymers, is more limited in material diversity but excels in producing high-strength and detailed polymer parts. Since SLS has been around longer, it has a broader range of materials available, including polymers and metals. This makes SLS more adaptable to a diverse range of applications.

Surface Finish Quality

While MJF often has a smoother surface finish right out of the printer compared to SLS, SLS parts can achieve unparalleled finishes through post-processing. The nature of the SLS process ensures that intricacies and details are better preserved even at higher packing densities, making it ideal for production applications.

Customization Opportunities

Both technologies are used for production manufacturing applications, however they differ significantly when it comes to fine-tuning the printing process for the best outcome.

With MJF, there are three print modes: fast, balanced, and mechanical. The fast mode prints parts quickly, while sacrificing the mechanical performance of the part. The mechanical setting sacrifices speed in lieu of higher mechanical performance. The balanced mode tries to create a happy medium between these other two build modes. Other than that, many other print settings are locked down.

For the experienced user, SLS offers a whole host of parameter sets that a user can augment to ensure their parts come out exactly the way they want. This can include laser power, scan speed, contouring, infill, temperature, and more. With over 25 parameters at your fingertips, a fantastic part is within reach.

Dimensional Accuracy

Although MJF is known for its precision due to its jetting process, SLS’s laser technology can fine-tune details with more control, rendering it superior for high dimensional accuracy while maintaining mechanical strength.

3D Printer Cost

SLS technologies are traditionally more expensive, but with advancements and a broader range of options, they are becoming far more accessible. MJF printers can be cost-competitive and are known for their speed, which can be a factor in high-volume production scenarios. Furthermore there is a significant amount of consumables one must account for in MJF printing like print heads, detailing and fusing agents, and cleaning rolls. These consumables can add thousands to your cost of operation each month.

Print Speed

MJF is renowned for its rapid production capabilities, which can be a significant advantage in high-volume or time-sensitive scenarios. While some SLS 3D printers aren’t as fast as MJF, SLS balances speed, and quality. The added time in SLS is a worthy trade-off for applications where precision and material properties are paramount.

Production Throughput

MJF’s quick printing speed allows for high production throughput. However, SLS can provide similar levels of output with greater control over the printing process as well as wider material options.

This adaptability makes SLS a reliable choice for specialized production, where quality can’t be compromised.

Sustainability

MJF requires a higher ratio of ‘virgin’ to recycled powder mix, which creates more waste than SLS platforms. It uses an optical sensor to verify powder quality and discoloration, however this powder is often still usable even when deemed “waste” in the MJF process.

Nexa3D’s QLS series, for instance, allows for higher powder recyclability rates, making it a more sustainable option for material usage. Additionally the QLS series can print in 100% HP waste powder, turning SLS in a virtually zero-waste process. SLS’s commitment to sustainability is an invaluable asset for environmentally-conscious operations.

MJF vs SLS: Choose the Right 3D Printer For Your Needs

MJF and SLS technologies each boast unique strengths and limitations. Ultimately, the decision between MJF and SLS should be rooted in the specific requirements of your projects. With its versatility, precision, and sustainability, SLS is often the superior choice, especially for applications requiring detailed features and diverse materials. However, MJF’s rapid printing speeds should not be overlooked.

If you’re looking for a versatile, sustainable, and precise 3D printing solution, Nexa3D’s range of SLS printers is an exceptional choice. The Nexa3D QLS series exemplifies the best SLS technology with its high speed, accuracy, and scalability. The ability to reuse materials and the detailed control over printing processes make it an invaluable tool for professionals who demand the best. Nexa3D’s commitment to innovation and quality ensures that you invest in a solution that consistently delivers superior results.

Don’t compromise on your 3D printing needs—embrace the future of additive manufacturing with the precision, versatility, and sustainability of Nexa3D’s SLS technology.

Learn more about Nexa3D SLS printers

Or read our complete guide to SLS 3D printing.