- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Resin 3D Printing utilizes liquid resins to create highly accurate and detailed objects. It’s a popular additive manufacturing technique for producing complex parts and components with extraordinary detail.

Whether you’re new to resin 3D printing or looking to deepen your understanding of this method, this comprehensive guide will explore the resin 3D printing process, various types of resin 3D printers, and safety tips to remember.

What is Resin 3D Printing?

Resin 3D printing is a type of additive manufacturing technology that uses liquid resins to craft objects. This 3D printing type is also known as vat photopolymerization: the process uses short wavelength light to solidify liquid resin into 3D pieces.

In most resin 3D printers, the process starts with a build platform filled with liquid resin. The 3D printer then emits light to create each object layer. As the light passes through the vat and curing layer, it solidifies or cures the liquid resin into solid pieces. This process continues until all layers have been printed.

Over the years, several generations of resin 3D printers have emerged, each with unique features and benefits. Here are some of the most common types of resin 3D printing technology:

- Stereolithography (SLA): SLA technology is the first generation of resin 3D printing. It uses lasers to cure liquid resin into solid pieces. SLA printers have resin tanks with a build platform exposed to laser light. They’re ideal for detailed and intricate designs that require a high level of accuracy, as well as very large parts.

- Digital Light Processing (DLP): This type of resin 3D printer uses shorter wavelength light to cure the resin material, almost like a home theater projector. While it was a new generation in resin 3D printing, the speed vs quality tradeoff persists. Although the print speed may not be affected, DLP projects from a single source point. This means the light is projected at varying angles which can affect the pixel shape at different spots (i.e. round in the center but oblong at the perimeter). This makes it challenging to produce images with complex geometries and accurate build quality. Plus, DLP chips and components can be expensive.

- Masked Stereolithography (mSLA): mSLA is the latest generation of SLA 3D printing that uses masks to control where light reaches the build plate. The masked stereolithography emerged to solve the quality issues that DLP couldn’t. Masked light ensures that only specific areas are exposed to the light, allowing for highly detailed prints that can be printed faster than the traditional SLA printers. Plus, since it projects pixels straight on, it creates more consistent parts from edge to edge. Plus, the LCD panels used in this process are much more readily available than DLP chips, and at resolutions of 8k and beyond. This leads to overall faster printing speed and reduces the cost of producing objects.

Photopolymer resins have allowed 3D printers to craft complex objects that other 3D printing methods cannot. With the precision and accuracy that resin 3D printing provides, this technology has become the best choice for product designers and engineers looking to produce complex parts with intricate details.

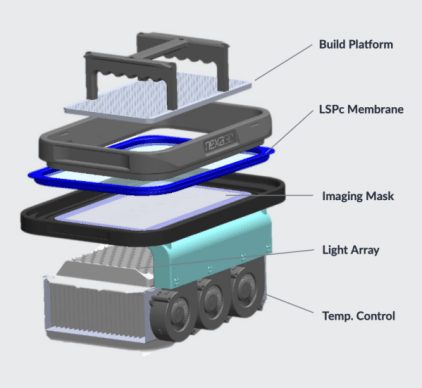

For example, Nexa3D’s Lubricant Sublayer Photo-curing (LSPc) technology, a patented mSLA variant technology, combines a light array and collimated optical lens layer to ensure light uniformity at an ultrafast speed.

Technical Review of LSPc®

Unleash your manufacturing potential with this guide, which explores the limitations of traditional SLA, offers a technical overview of Lubricant Sublayer Photo-curing (LSPc), and shows you how to achieve up to 20x productivity gains.

Nexa3D’s LSPc technology goes a step further utilizing a patented lubricated Everlast 2 membrane. This membrane significantly reduces the “peel force” imposed as each layer is lifted off of the base of the vat. It provides the fastest printer on the market with the largest build area in its class, all without sacrificing image quality.

Resin 3D Printing vs. Filament 3D Printing

Filament 3D printing is a material extrusion additive manufacturing process that uses molten plastic filament that is extruded through the nozzle of a 3D printer. Also referred to as fused deposition modeling (FDM) or fused filament fabrication (FFF), this method has been around for decades and is one of the most popular 3D printing processes.

While both resin 3D printing and filament 3D printing can produce high-quality prints, there are some notable differences between resin 3D printing and filament 3D printing. Some of the differences include:

- Print Quality: Resin 3D printing delivers finer details and a smoother surface finish than filament 3D printing. The resin material is cured or solidified in layers, allowing for greater precision when it comes to creating intricate designs, while filament printers stack extruded filament (a material limited to a more macro scale). Resin 3D printers can also print at a low 10-micron resolution which is much finer than the resolution of filament 3D printers.

- Speed: Filament 3D printers are going to be some of the slowest since they need to physically move the extruder around to draw the entire part. The evolution to DLP and now mSLA has allowed for a whole build plate of parts to be printed in the same time it might take to print a single part because full image is “projected” onto the resin with no need to draw it out.

- Materials: Resin 3D printing accommodates various materials that are formulated specifically for resin 3D printers. They can range from flexible resins to ceramic-like resins that create pressure, temperature, and chemical-resistant parts. Filament 3D printing frequently uses filaments such as PLA, ABS, and PETG. Other printing materials like Nylon, PA, PETG, TPU, PEEK, and PEI can be used, but they’re often limited to specific professional FDM printers that can support them.

- Accuracy: Resin 3D printers have higher accuracy than filament 3D printers. Because the layer thickness can be as thin as 10 microns builders can print more intricate designs with greater detail.

Resin 3D Printing Process

3D printing companies have different resin 3D printing processes and techniques that make the process easier and faster.

1. Using CAD & Slicing Software

CAD (computer-aided design )software is used to create a 3D model. The CAD file is then placed in build setup software, the build parameters are set, and this is sent to the printer.

Once the product is designed, it needs to be transferred from a (CAD) application to slicing software for printing preparations. This slicing software uses algorithms to create individual layers of the 3D model based on the chosen printing process and material. The more detailed the object, the more layers it will have.

This can be the longest part of the resin 3D printing process, especially if the 3D printer uses regular software with a slower processing time. However, 3D printer companies have developed dedicated slicing software to speed up this part of the process.

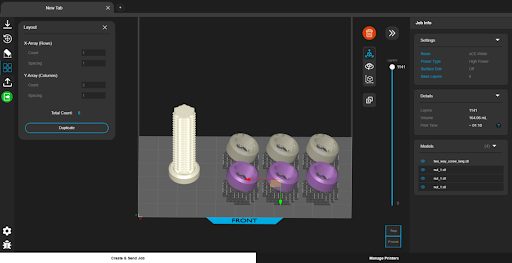

For example, Nexa3D’s NexaX software offers an intuitive user interface and advanced features like automatic support generation and remote monitoring to make the most complex tasks easier. NexaX software enables process stability and print consistency, making it easy to scale from prototyping to full-scale production by slicing thousands of layers, generating supports, simulating and validating the build process, and then creating the file for the 3D printer.

2. Print the Product

Once the slicing software is done with its job, it’s time to print and create a 3D object. This step involves pouring the resin into a vat and putting the build platform inside.

The 3D printer then uses a light source to cure the resin layer-by-layer until the desired object is printed completely. Printing is completely automatic: unlike machining and hand tooling, once you hit print, you can walk away and come back to a completed part. This greatly improves worker productivity and can remove the need for dedicated machinists or technicians.

It’s still important to know that different resin printing technologies have different curing times as well as different temperatures and pressure requirements. During printing, there may be errors in the object due to unsuitable material or other issues like too much light exposure, excessive heat, or incorrect resin formulation.

Advanced 3D printers come with built-in 3D software that spots potential issues and processing techniques can also be used to fix any problems that may arise during the 3D printing process. Other printers–particularly consumer-grade 3D printers–require manual settings to be adjusted.

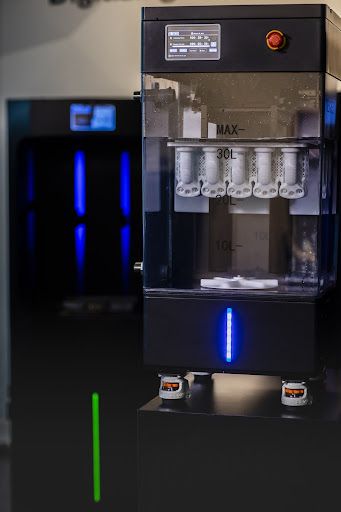

The Nexa3D XiP 3D Printer is a perfect example of a 3D printer with in-built NexaX software that virtually separates elements and generates instructions to print in a manner that drives heat into the resin tank, where it dissipates. NexaX also has validated material profiles pre-loaded, which makes the printing process much easier and more reliable.

The XiP combines a compact footprint with a large build volume and fast print speed to deliver high-quality prototypes. Builders can print objects rapidly without worries over thermally-induced quality issues.

3. Post-processing

This step involves removing any excess material from the print and ensuring it’s aesthetically pleasing. It also includes sanding off rough edges and applying paint or coatings for better durability.

This step is essential for producing an amazing 3D print but it can be time-consuming. Again, advanced technology makes the post-processing stage seamless. For example, Nexa3D’s xWash and xCure post-processing technologies integrate post-processing features so that operators no longer need to manually remove excess materials or apply special coatings after printing.

Resin 3D Printing Materials & Components

What do you need for resin 3D printing?

The Resin

Over 30 materials are available for Nexa3D’s photopolymer NXE 400.

Resin 3D printing primarily uses photopolymers which are a type of plastic that is infused with photoinitiators. It often starts as a liquid and cures into a solid form when exposed to light. Depending on the type of resin used, the end product can be rigid or flexible, and resins can vary in durability and elasticity.

The most common photopolymers used for 3D printing are epoxy resins, acrylic resins, and polyurethane. Epoxy resins produce the highest resolution 3D prints and are most suitable for prototyping. They also have superior mechanical properties, such as strength and durability, making them perfect for production-grade printing.

Acrylic resins are commonly used for producing highly detailed objects due to their low shrinkage and high print resolution. Polyurethane resins are flexible, making them ideal for printing medical devices and other high-impact parts.

These resin materials make this 3D printing technology perfect for producing complex models and intricate details.

2023 Material Guide for Ultrafast 3D Printing

Learn about the latest ultrafast 3D printing materials in 2023 and what other types of materials can be 3D printed in minutes. Check out the guide.

Design & Slicer Software

CAD software, or computer-aided design software, is used to create 3D models. This makes it easier to customize them according to the user’s needs. Slicing software then configures the 3D model and the printing parameters and produces a file that can be sent to the printer.

Most regular 3D printers use open-source slicers for resin 3D printing, including Simplify3D, Cura, PrusaSlicer, Slic3r, Chitubox, etc. Each slicer has its features and customization options to choose from, depending on the printer.

Advanced 3D printers have patented slicer software that offers sophisticated features like automatic resin optimization and auto-leveling. Nexa3D’s NexaX software is a perfect example of proprietary slicer software that simplifies the resin 3D printing process. It offers print preparation and 3D printer management software with API integration for other software to unlock new properties for printed parts while enabling process stability, higher yields, consistent product quality, production scaling, and unmatched mechanical performance.

With these programs and materials, operators can enjoy a fast, accurate, and reliable 3D printing experience with resin 3D printers.

Post-processing Materials

After a print job is finished, builders must apply a range of liquids, solvents, and abrasives for cleaning and finishing their parts. Generally, post-processing materials used with resin 3D printing include:

- Cleaning: 3D-printed parts need to be cleaned with isopropyl alcohol (IPA) or other suitable cleaning solutions. Also known as rubbing alcohol, IPA is the most common solvent used for removing uncured resin from 3D-printed parts while ensuring they still look their best.

- Support Removal: The support material in 3D printing needs to be removed to reveal the intricate parts. This can be done with hand tools, ultrasonic cleaning systems, and water-soluble support materials that dissolve over time in the water.

- Polishing: Most 3D printed parts need some polishing before they’re complete. Polishing helps improve the surface quality and increase the strength of 3D-printed parts. This post-processing step is usually done with abrasive pads, polishers, and sandpaper to achieve the desired finish.

- Smoothing Agents: The surface of 3D-printed parts can be made smoother with a smoothing agent. This is typically used for post-processing and finishing 3D prints since it helps fill in any gaps on the surface.

While these post-printing materials help achieve the desired aesthetic and mechanical properties for parts, different methods of resin 3D printing require different levels of post-processing. For example, mSLA printers have a full LED light array that projects light straight upward across the entire build plate. This prevents distortion that can occur with SLA and DLP printers.

Resin 3D Printer Types

Resin 3D printers come in different sizes, shapes, and features. Depending on the budget and application requirements, users often choose between professional and consumer-grade printers. The former is most suitable for architects, engineers, industrial designers, and many other professionals who need precise parts for their applications, while hobbyists can rely on consumer-grade printers.

Small-format (Desktop) Printers

Small-format resin 3D printers are most suitable for small businesses and creative professionals. These desktop machines offer accuracy, speed, and repeatability with smaller build volumes and can be used to make parts ranging from consumer products to small electronics.

Nexa3D’s XiP offers industrial-quality 3D printing at an affordable desktop price. The XiP combines a compact footprint with a large build volume and fast print speed to deliver high-quality prototypes right to your desktop.

Large-format Printers

Large-format printers are primarily used by large companies that need more space for their prints. These machines offer a larger build area and can be used to make parts such as furniture, automotive parts, and medical implants.

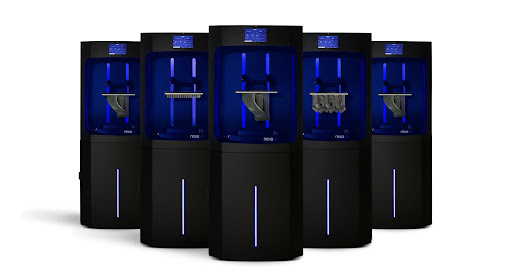

The Nexa3D NXE 400Pro is an ultrafast industrial 3D printer that boasts an unprecedented 17L build volume without compromising on accuracy or repeatability.

Resin 3D Printing Safety Notes

Just like all methods of 3D printing, it’s important to implement safety precautions. Here are a few safety tips for resin 3D printing:

- Use a Ventilated Space: Due to the materials used in the printing process, builders should set up the 3D printer in a well-ventilated area or use an enclosed 3D printer with an inbuilt ventilation system.

- Avoid Contact with Uncured Resin: Uncured resin can be harmful if it gets in contact with the skin and eyes. Always wear protective gloves, eye protection, and a mask when working with uncured resin or cleaning 3D-printed parts.

Resin 3D Printing FAQs

What is resin 3D printing used for?

Resin 3D printing has various applications including prototyping, tooling, and production parts. It offers superior mechanical properties, high accuracy, resolution, and faster turnaround times compared to other 3D printing technologies.

How expensive is resin 3D printing?

Resin 3D printing does require specialized equipment and materials to be used. The total cost depends on the type of resin and printer used and the complexity of the printed parts.

And while resin-based printers are typically more expensive up front than FDM 3D printers, they almost always provide more value to professional users. Vat polymerization delivers better part quality, smoother finishes and finer detail, greater throughput, and build chamber utilization (especially mSLA 3D printers).

How long do resin prints last?

Resin prints typically last for several years with proper care and maintenance. The lifespan of a resin print may vary depending on the resin type and exposure to light, moisture, and extreme temperatures.

What are 4K resin printers?

4K resin printers are a type of 3D printer that use a higher resolution of a 4K LCD screen, usually around 3840 x 2160 pixels. This allows for finer details and higher accuracy, making them ideal for printing highly detailed parts.

Use the Best Resin 3D Printer

Resin 3D printing is the best way to create high-quality parts with superior accuracy and resolution. But with so many types of resin 3D technologies and printers available on the market, it’s critical to choose the right one for your product.

Nexa3D XiP desktop 3D printers offer the highest precision, speed, and the easiest setup and maintenance for professionals. With its intuitive software and versatile material range, Nexa3D XiP gives the perfect combination of speed and accuracy at an affordable price.

The industrial Nexa3D NXE printer series follow the same high speed and accuracy philosophy but with a larger build volume and 4K LCD screen for incredible detail, accuracy, and resolution. These printers also offer a range of material options for an even wider range of applications.

Ready to experience it yourself?

Request a free sample part from our ultrafast resin 3D printers.