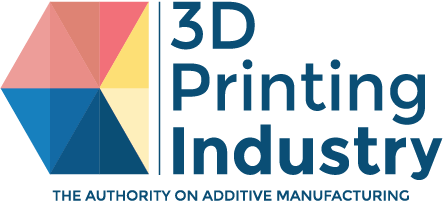

MotoCilino Discovers New Standard of Desktop 3D Printing

Engineering services firm accelerates design iteration and validation with the help of XiP

Paul Cilino is an engineer, designer, and inventor. In 2017 he opened his own engineering consulting firm—MotoCilino. The firm, which specializes in 3D modeling using CAD, 3D scanning for reverse engineering, and 3D printing for prototyping, and one-off production, is one example of a growing global trend of individual entrepreneurial engineering consultants.

Cilino cut his teeth working in his family machine shop before going to school for mechanical engineering at University of Texas. It was there that Cilino first got exposed to additive manufacturing. “I was familiar with the machining process, and the idea that [with additive] you could go and make something without having to worry about fixturing and programming toolpaths – it was an amazing thing.” After school he had stints at Raytheon and Georgia Tech but realized in 2016 that with tools like desktop 3D printers, and his knowledge of CAD, he could start his own business designing and engineering products for all sorts of clients.

Customer

MotoCilino

Industry

Engineering Services

Products

- XiP Desktop 3D Printer

- xPRO 410 Resin

- xABS 3843 Resin

Application

Prototyping for New Product Development

Advantages

- Able to print more advanced geometries

- Reduced support structures

- Superior build quality for reliability

- Adopt a less conservative approach to iteration

- Reduced barrier to print iterations thanks to high speed

3rd-Party Engineering Report on the XiP Desktop 3D Printer

Engineer’s Report – November 2022 by 3D Printing Industry Prepared by: Maël DUPORTAL

What’s in the Report?

- Packaging, Hardware, and Slicer Reaction

- Use of Printer

- Basic Printing Tests (Dimensional Accuracy, Repeatability, etc)

- Real Application Printing Tests (includes gearing, bike pedal, ULA rocket bracket, and generative design bottle holder)

- Post-Processing

- Conclusions

Download the Full 56 Page Report

Challenge

Limited by Desktop 3D Printing Speed and Quality

Cilino operates in a wide range of industries including motorsport, biomedical, consumer electronics, and defense – really any company that needs help developing a hardware product. He swears by the power of 3D printing when it comes to working with his customers. “Some customers respond much more effectively when holding a physical part – screen captures, renders, animations are all useful, but there’s no substitute for a physical part.”

Cilino has grown his fleet of desktop 3D printers since opening up his consulting business. Up until recently he had three FDM 3D printers and one SLA machine from Formlabs, but as he contemplated offering more complex, generative style geometries he realized that he needed something different. “The Form 2 was a bit of a disappointment because of my misplaced expectations,” recalls Cilino. “I thought the process would be faster, I thought the level of details would be better than what I was experiencing, and it also donned on me that because of the way the platform is built, it’s just not that capable of producing advanced geometries because of the force that is imposed as each layer is advanced – or at least not without a tremendous amount of supports.” When the next evolution of that 3D printer came to the platform (the Form3), he could see that the core issues had not been resolved, and decided to hold out for something different.

Solution

Next-Gen Geometries on a Next-Gen Desktop 3D Printer

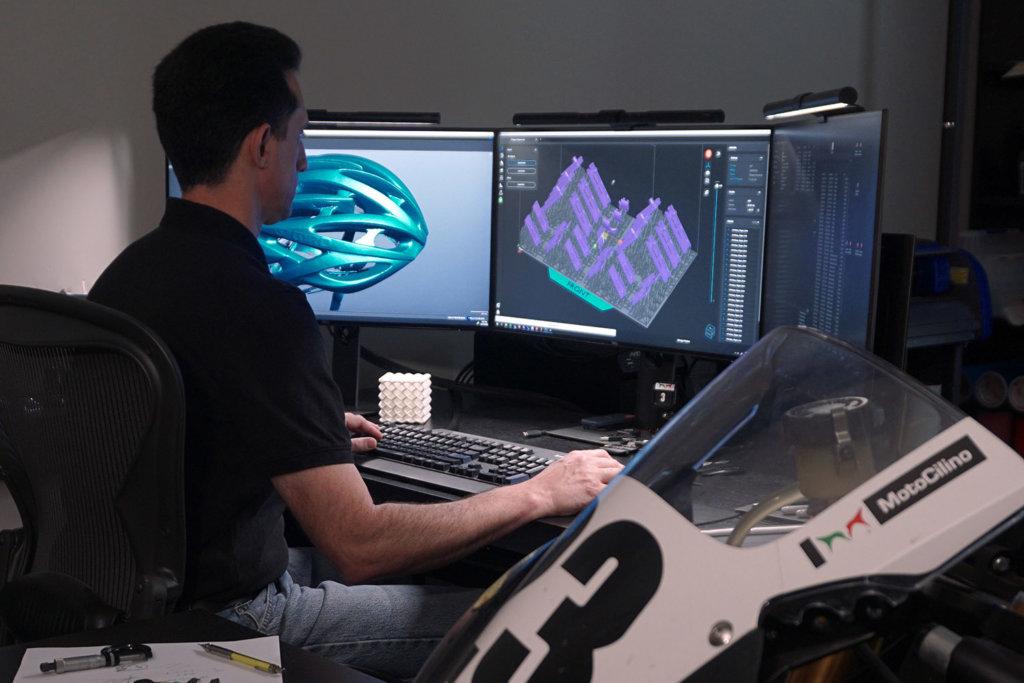

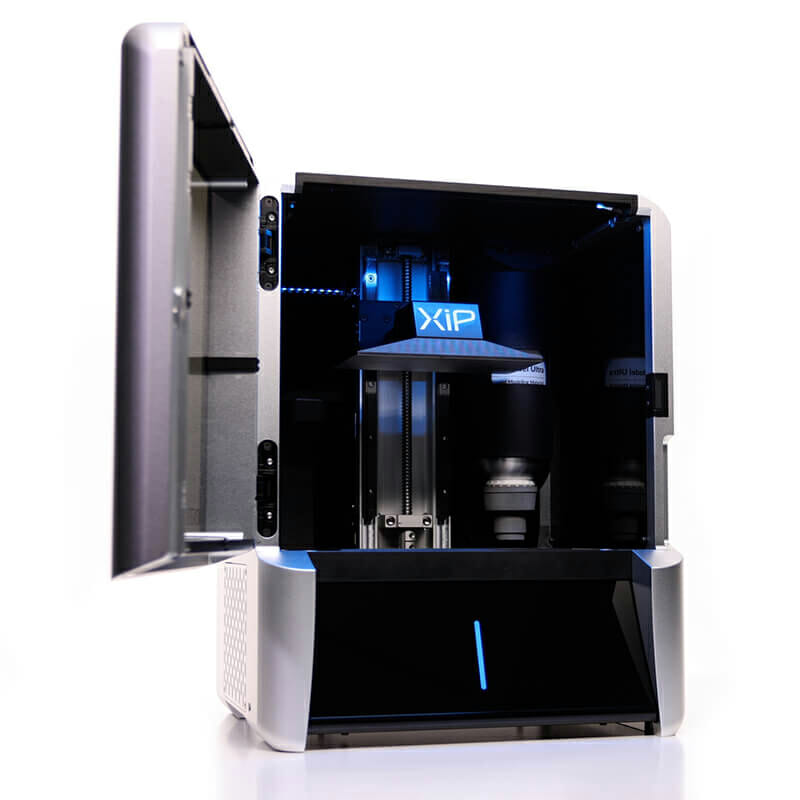

Cilino learned about Nexa3D through the NXE 400 industrial 3D printer, but the price put it out of range for what he could afford. When XiP was announced in late 2021, Cilino didn’t skip a beat and became one of the first pre-order customers for the platform. “The ability of XiP to print with reduced forces in the process was the best fit for achieving these next generation geometries.”

The proprietary technology behind NXE 400 (and now XiP) that caught Cilino’s eye allows for very low forces to be imposed on the print as each layer moves up – Nexa3D calls it Lubricated Sublayer Photocuring or LSPc for short. Cilino has clearly done his homework as he describes the pros and cons of today’s inverted resin 3D printers and how LSPc is a game changer. “The original SLA 3D printers required a massive vat of resin because of how they operated with the printer part moving down into the resin. Now with these inverted systems, all you need is a thin pool of resin, but the downside is that you create a force on the part as it’s printing which you need to shear off from the bottom of the vat which can really damage a complex part unless it is loaded with supports. [LSPc] overcomes that by using a lubricated membrane that allows the part to release with much less force (and more quickly).”

While Cilino’s focus was primarily on complex geometries, he has also noticed a tremendous reduction in print time compared to the other 3D printers in his fleet.

“It removes this cognitive weight of ‘well it’s going to take 13 hours to process this part and I really don’t want to invest this kind of time and effort on a throwaway shot’. On [XiP] that really doesn’t happen, it takes you a step closer to printing out a sheet of paper. You can just iterate rapidly without being punished for forgetting to put a hole in the part or make the boss the right size – you can just fire off another print and it doesn’t really matter.”

“With XiP’s large build volume, fast print speed, and easier post processing due to less supports, I’m able to iterate faster and validate new designs in hours versus days.”

Paul Cilino, Mechanical Engineer and Owner

A Desktop 3D Printer Built to CNC Standards

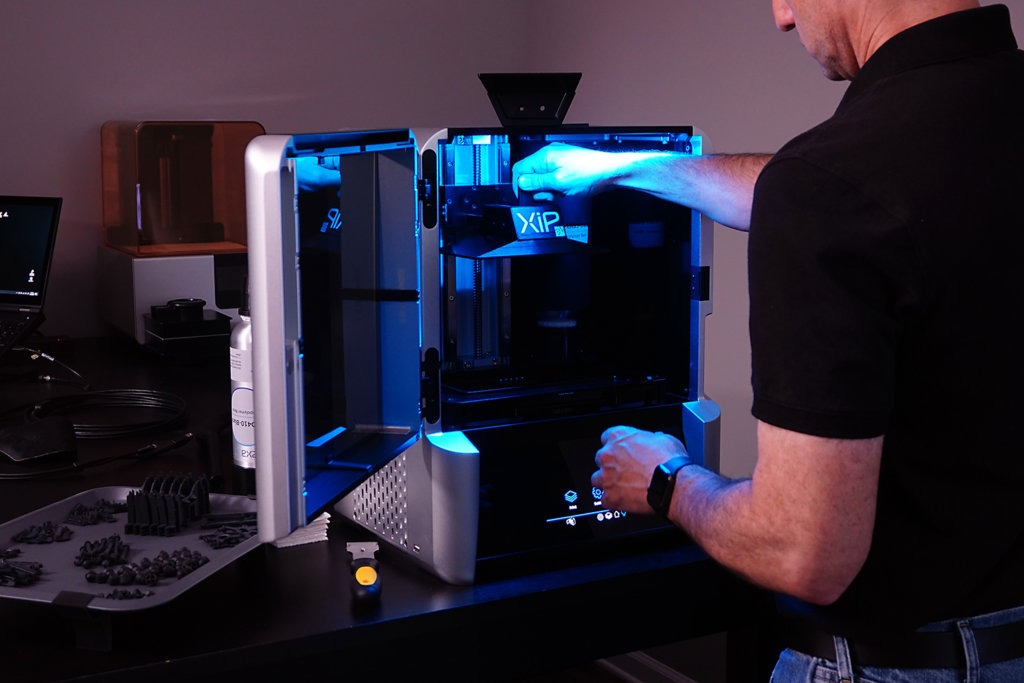

Revolutionary tech is great, but sometimes with new products (and especially in the desktop 3D printer space) you see corners cut when it comes to build quality, but Cilino could tell right when he received his XiP that it was built different. “That machine when it came boxed, packaged, and on the pallet the way it did – there was no corner cut, as professional and industrial as I’ve seen any piece of CNC equipment or lab equipment packaged. This is truly professional-grade – it’s second to none.”

The presentation of packaging aside, Cilino was blown away by the many machined components. “As an ex-machinist I can tell you that the part, fit, and finish of [XiP] is quality in every way, shape, and form, and it deserves to get recognized for that. One thing that really impressed me was the solid aluminum build vat. I looked at the tool marks, I looked at all that stuff, it’s truly something special.”

In the burgeoning space of the work from home, design / engineering consultant, it’s clear that the desktop 3D printer plays an invaluable role – bringing a bit of the workshop into the home office. With the advent and growth in popularity of the next generation of high speed desktop 3D printers – like XiP – there is a new professional standard enabling exceedingly complex parts to be manufactured in less time, and, as Cilino points out, with unprecedented reliability, “I will say this, I’ve been using XiP for four months now, and I have yet to have a failed build so far.”