3D Printing Materials

While all of Nexa3D printers are built on an open material platform, we offer a broad and growing selection of already qualified materials for all of your resin and thermoplastic 3D printing needs.

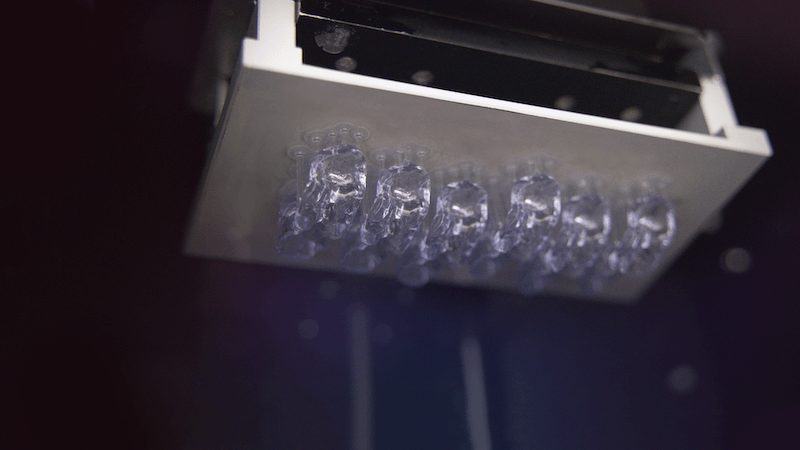

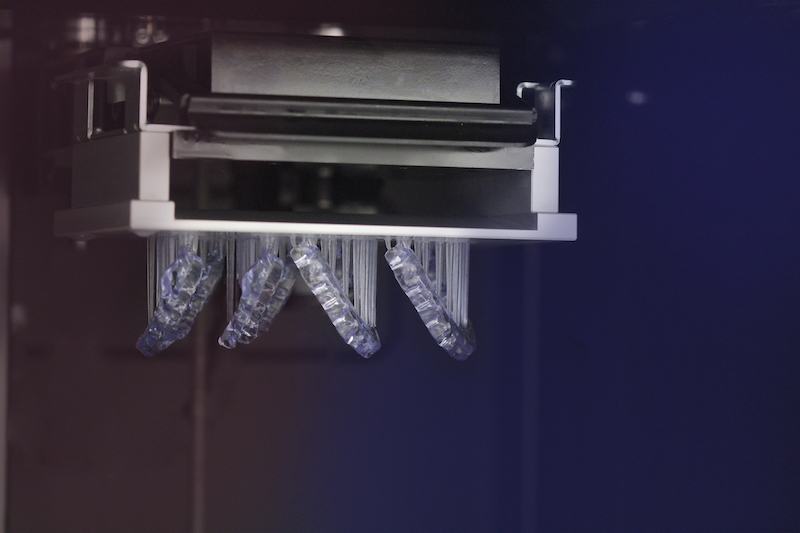

Resin 3D Printing Materials

Use with XiP Pro, NXE 400Pro, and XiP

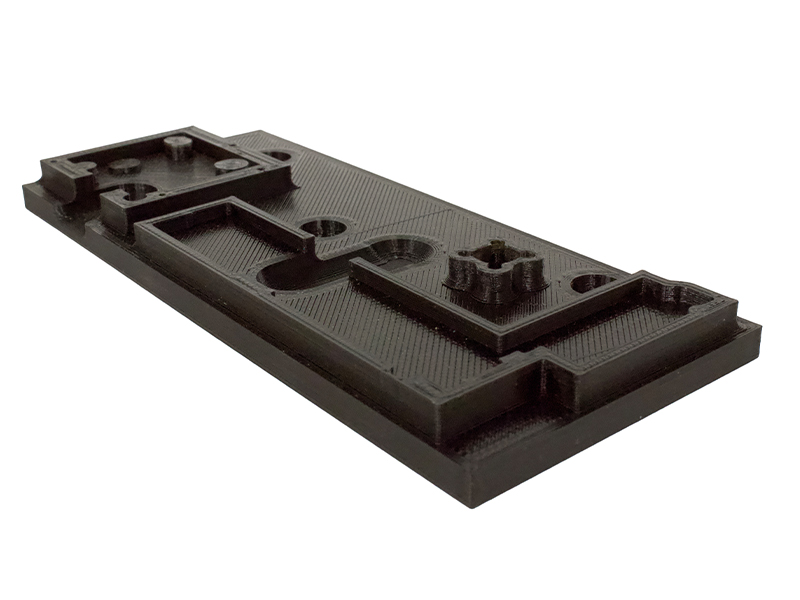

Plastic and Metal Powder Materials

Use with QLS 820, QLS 260, and QLS 230

-

9085

Industrial parts, heat-resistant components, sustainable projects, high-detail prints.Measurement Value Unit Test Method Ultimate Tensile Strength 79.5 (2.8) MPa ISO 527-2 Tensile Modulus 2.44 (0.05) GPa ISO 527-2 Strain at Break 6.9 (1.8) % ISO 527-2 Flexural Strength 125 (1) MPa ISO 178 Flexural Modulus 2.53 (0.04) GPa ISO 178 Notched Izod Impact Strength 8.4 (3.2) kJ/m2 ISO 180/A -

Essentium Altitude™

Outdoor applications, high-altitude, drones, electrical components, transformer housings.Measurement Value Unit Test Method Ultimate Tensile Strength 58.14 MPa ISO 37 Tensile Modulus 3.74 GPa ISO 37 Strain at Break 2.25 % ISO 37 Notched Izod Impact Strength 34.557 kJ/m2 ISO 180/A Flexural Strength 93.14 MPa ISO 37 Flexural Modulus 1.96 GPa ISO 37 -

Essentium Duratem™

Aerospace, defense, electrical, energy management, material handling, rail components.Measurement Value Unit Test Method Ultimate Tensile Strength 40.0 (0.8) MPa ISO 37 Tensile Modulus 465 (10) GPa ISO 37 Strain at Break 129 (15) % ISO 37 Notched Izod Impact Strength — kJ/m2 ISO 180/A -

Essentium PCTG

Handheld tools, gauges, location fixtures, general assembly fixtures, check sockets for prosthetics.Measurement Value Unit Test Method Ultimate Tensile Strength 44.0 (0.2) MPa ISO 527-2 Tensile Modulus 1.81 (0.03) GPa ISO 527-2 Strain at Break 130 (1) % ISO 527-2 Flexural Strength 72.7 (0.9) MPa ISO 178 Flexural Modulus 1.78 (0.01) GPa ISO 178 Notched Izod Impact Strength 7.5 (0.5) kJ/m2 ISO 180/A -

HTN

Jigs and fixtures, electrically insulating parts, electronic housings, low-speed gears.Measurement Value Unit Test Method Ultimate Tensile Strength 76.9 (1.0) MPa ISO 527-2 Tensile Modulus 3.18 (0.31) GPa ISO 527-2 Strain at Break 7.3 (1.3) % ISO 527-2 Flexural Strength 129 (3.0) MPa ISO 178 Flexural Modulus 3.10 (0.11) GPa ISO 178 Flexural Modulus 3.4 (0.3) kJ/m2 ISO 180/A -

HTN – CF25

Injection molds, thermoforming, blow molding, jigs and fixtures, high-strength parts, aluminum part replacements.Measurement Value Unit Test Method Ultimate Tensile Strength 148 (4) MPa ISO 527-2 Tensile Modulus 16.0 (0.35) GPa ISO 527-2 Strain at Break 1.4 (0.1) % ISO 527-2 Flexural Strength 184 (5) MPa ISO 178 Flexural Modulus 11.4 (0.5) GPa ISO 178 Notched Izod Impact Strength 9.2 (1.3) kJ/m2 ISO 180/A -

HTN-Z

Assembly aids for electronics, ESD-safe fixtures, electrical housings, part trays for electronics manufacturing.Measurement Value Unit Test Method Ultimate Tensile Strength 72.8 (0.4) MPa ISO 527-2 Tensile Modulus 3.45 (0.44) GPa ISO 527-2 Strain at Break 120 (25) % ISO 527-2 Flexural Strength 134 (2) MPa ISO 178 Flexural Modulus 3.73 (0.24) GPa ISO 178 Izod Impact Strength 3.6 (0.5) kJ/m2 ISO 178 -

INFINAM® PA 6002 P (PA 12)

Functional prototypes, Producing individualized units, Manufacturing serial partsMeasurement Value Unit Test Method Tensile Modulus 1700 MPa ISO 527 Tensile Strength 50 MPa ISO 527 Nominal Strain at Break 16 % ISO 527 -

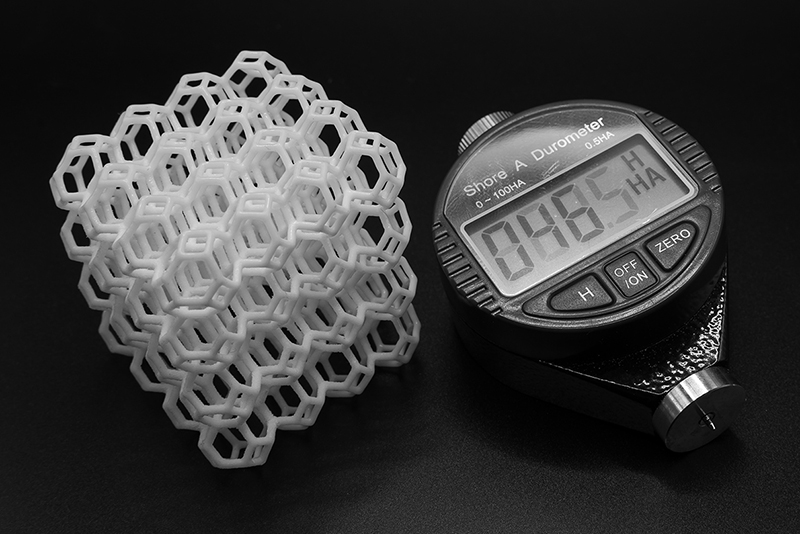

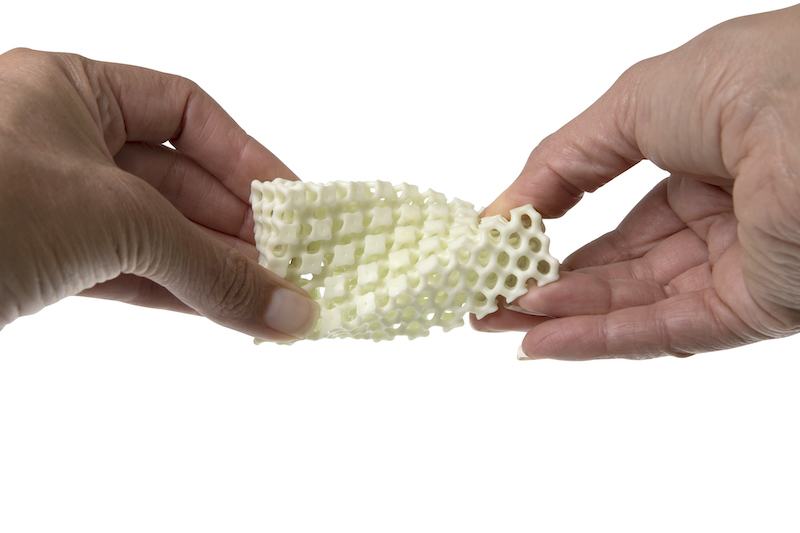

INFINAM® TPC 8008 P

Orthotic and prosthetic, thin walls, excellent chemical and abrasion resistance, good surface finishMeasurement Value Unit Test Method Tensile Modulus 131 MPa ASTM D 638 Strain at break 440 % ASTM D 638 Tear Strength 130 kN/m ASTM D 624 Taber Abrasion Resistance 117 mg/1000 cycles ASTM D 1044 DTUL @ 66 psi 85 °C ASTM D 648 Hardness (Shore D) 46 ASTM D 2240 Melt Flow Index, MFI 35.7 g/10min ASTM D 1238 Charpy impact strength, +23°C N kJ/m² ISO 179/1eU Charpy impact strength, -30°C 88 kJ/m² ISO 179/1eU -

KeyGuide

Ideal for printing transparent surgical guides for proper implant placement at a precise angle and depthMeasurement Value Unit Test Method Flex Modulus 2400 MPa ASTM D790 Flex Strength 105 MPa ASTM D790 Biocompatibility Pass /ISO 10993-5 Biocompatibility Pass /ISO 10993-10 -

KeyModel Ultra – Ivory

Dental Thermoforming, Dental Removal Die and Model ApplicationMeasurement Value Unit Test Method Tensile Modulus >1700 MPa D638 Ultimate Tensile Strength >50 MPa D638 Tensile Elongation at Break 5 % D638 Flex Modulus >1940 MPa D790 Flex Strength >70 MPa D790 -

KeyModel Ultra – Light Gray

Dental Thermoforming, Dental Removal Die and Model ApplicationMeasurement Value Unit Test Method Tensile Modulus >1700 MPa D638 Ultimate Tensile Strength >50 MPa D638 Tensile Elongation at Break 5 % D638 Flex Modulus >1940 MPa D790 Flex Strength >70 MPa D790 -

KeyOrtho IBT

Highly-Precise Indirect Bonding TraysMeasurement Value Unit Test Method Tensile Strength (MPa) 8.0 – 10.5 MPa ASTM D638 Tensile Young’s Modulus (MPa) 15.5 – 31.0 MPa ASTM D638 Elongation at Break (%) >130 % ASTM D638 Biocompatibility Pass ISO 10993-5 Viscosity @ 25°C (cP) <1000 ASTM 7867 Orthodontic Adhesive Release Pass -

KeySplint Hard

Rigid Hard SplintsMeasurement Value Unit Test Method Flexural Strength 60-65 MPa ISO 20795-2 Flexural Modulus 1510-1600 MPa ISO 20795-2 Water Sorption 18 μg/mm3 ISO 20795-2 Elongation at Break 9 % ASTM D638 Biocompatibility Pass ISO 10993 -

KeySplint Soft

Splints, Night Guards, Bleaching TraysMeasurement Value Unit Test Method Tensile Elongation at Break >110 % D638 Flex Modulus 1100 MPa ASTM D790 Flex Strength 44 MPa ASTM D790 Flex Modulus 135 MPa ISO 20795-2 Flex Strength 2.6 MPa ISO 20795-2 Hardness (Shore D) 80 ASTM D2240 HDT @0.45 MPa 32 oC ASTM D648 Sorption <18 μg/mm3 ISO 20795-2 Solubility <4.8 μg/mm3 ISO 20795-2 Free Monomer Extraction Pass ISO 20795-2 Cytotoxicity Pass ISO 10993 Irritation Pass ISO 10993 Sensitization Pass ISO 10993 -

KeyTray

Custom Impression TraysMeasurement Value Unit Test Method Tensile Modulus/ASTM D638 2056 MPa ASTM D638 Ultimate Tensile Strength 62 MPa ASTM D638 Tensile Elongation at Break 26 % ASTM D638 Flex Modulus 1913 MPa ASTM D790 Flex Strength 85 MPa ASTM D790 Hardness (Shore D) 86 ASTM D2240 -

PA

Gears, mechanisms, low-friction bearings, thrust washers, automotive partsMeasurement Value Unit Test Method Tensile Strength 55 MPa ASTM D638 Tensile Modulus 2,180 MPa ASTM D638 Flexural Strength 73 MPa ASTM D790 Flexural Modulus 1,749 MPa ASTM D790 Specific Gravity2 1.12 % ISO 1183 Moisture (50%, RH)2 3.2 % ISO 62 Moisture (Sat)2 10.5 % ISO 62 Melting Point 82 °C ISO 3164 Heat Deflection Temp 10.5 °C ASTM D648 -

PA-CF

Handheld fixtures, automotive parts, brackets, covers, high-strength jigs, and fixtures.Measurement Value Unit Test Method Ultimate Tensile Strength 55.9 (0.3) MPa ISO 527-2 Tensile Modulus 2.16 (0.15) GPa ISO 527-2 Strain at Break 18 (1) % ISO 527-2 Flexural Strength 72.8 (1.6) MPa ISO 178 Flexural Modulus 2.39 (0.05) GPa ISO 178 Notched Izod Impact Strength 48 (2) kJ/m2 ISO 180/A -

PCTG-Z

Handheld tools, general assembly fixtures for electronics, robotics and automation components, parts for explosion-proof environments, ESD part trays.Measurement Value Unit Test Method Ultimate Tensile Strength 45.0 (0.5) MPa ISO 527-2 Tensile Modulus 1.81 (0.07) GPa ISO 527-2 Strain at Break 150 (27) % ISO 527-2 Flexural Strength 74.5 (1.1) MPa ISO 178 Flexural Modulus 1.72 (0.03) GPa ISO 178 Notched Izod Impact Strength 7.0 (0.6) kJ/m2 ISO 180/A -

PEEK

Jigs and fixtures, insulating parts, electronic housings, low-speed gears.Measurement Value Unit Test Method Tensile Strength 92 MPa ASTM D638 Tensile Modulus 3250 MPa ASTM D638 Elongation at Break 15 % ASTM D638 -

PEKK

Jigs and fixtures, insulating parts, electronic housings, low-speed gears.Measurement Value Unit Test Method Ultimate Tensile Strength 82.9 (1.0) MPa ISO 527-2 Tensile Modulus 3.04 (0.38) GPa ISO 527-2 Strain at Break 75.8 (12.0) % ISO 527-2 Flexural Strength 114.3 (1.7) MPa ISO 178 Flexural Modulus 2.37 (0.10) GPa ISO 178 Izod Impact Strength, Notched 5.5 (1.3) kJ/m2 ISO 178 -

PP-CF

Low-pressure resin casting molds, glue and adhesive bonding clamps, chemical processing parts, automotive parts.Measurement Value Unit Test Method Ultimate Tensile Strength 62.0 (0.4) MPa ISO 527-2 Tensile Modulus 7.28 (0.06) GPa ISO 527-2 Strain at Break 6.8 (0.3) % ISO 527-2 Flexural Strength 95.3 (1.8) MPa ISO 178 Flexural Modulus 5.13 (0.74) GPa ISO 178 Notched Izod Impact Strength 13.7 (0.5)-H kJ/m2 ISO 178 -

PPS-CF

Injection mold tooling, expanded foam mold tooling, aerospace parts, railway parts, oil and gas.Measurement Value Unit Test Method Ultimate Tensile Strength 63.0 (5.4) MPa ISO 527-2 Tensile Modulus 7.46 (0.33) GPa ISO 527-2 Strain at Break 2.2 (0.2) % ISO 527-2 Flexural Strength 98.2 (9.5) MPa ISO 178 Flexural Modulus 6.18 (0.49) GPa ISO 178 Izod Impact Strength, Notched 3.0 (0.7) kJ/m2 ISO 178 -

Pro ABS

High-strength applications, durable and heat-resistant projects, functional prototypes, and end-use parts.Measurement Value Unit Test Method Tensile Strength, 3.2mm @ Yield 1.04 D638 Tensile Elongation, 3.2mm @ Break 0.4~0.7 % D638 Tensile Modulus, 3.2mm 23 g/10min D638 Flexural Strength, 3.2mm 1.04 D638 Flexural Modulus, 3.2mm 0.4~0.7 % D638 Rockwell Hardness, R Scale 23 g/10min D638 Izod Impact Strength, 6.4mm Notched @ 23°C (73°F) / @ -30°C (-22°F) 20/8 kg º cm/cm D256 Izod Impact Strength, 3.2mm Notched @ 23°C (73°F) / @ -30°C (-22°F) 23/8 kg º cm/cm D256 -

Pro PCTG

Handheld tools, gauges, location fixtures, general assembly fixtures, check sockets for prosthetics.Measurement Value Unit Test Method Ultimate Tensile Strength 44.0 (0.2) MPa ISO 527-2 Tensile Modulus 1.81 (0.03) GPa ISO 527-2 Strain at Break 130 (1) % ISO 527-2 Flexural Strength 72.7 (0.9) MPa ISO 178 Flexural Modulus 1.78 (0.01) GPa ISO 178 Notched Izod Impact Strength 7.5 (0.5) kJ/m2 ISO 180/A -

PRO9499 White

Measurement Value Unit Test Method Tensile Modulus 1500 MPa ASTM D638 Ultimate Tensile Strength 40 MPa ASTM D638 Tensile Elongation at Break 8 MPa ASTM D638 Flex Modulus 2164 MPa ASTM D638 Flex Strength 95 MPa ASTM D790 Hardness (3s) 77 D ASTM D790 HDT @0.45 MPa 50 °C ASTM D648 Water Absorption (24hr) 0.21 % ASTM D570 -

ROLASERIT® PB-01

Seals for windows and cars, Grippers and tubes in automation, Orthopedic shoe soles and componentsMeasurement Value Unit Test Method Tensile Modulus 1300 MPa ASTM D638 Ultimate Tensile Strength 35 MPa ASTM D638 Tensile Elongation at Break 100 % ASTM D638 Flex Modulus 1300 MPa ASTM D790 Flex Strength 45 MPa ASTM D790 HDT @0.45 MPa 53 °C ASTM D648 Notched Izod 62 J/m ASTM D256 Water Absorption 1 % ASTM D570 Hardness Shore D 75 ASTM D2240 -

Saremco Print CROWNTEC

Measurement Value Unit Test Method Depth of cure ≥ 1.5 mm DIN EN ISO 4049) Flexural strength > 130 MPa DIN EN ISO 4049) E-Modulus > 4000 MPa DIN EN ISO 4049) Barcol-Hardness > 40 -

Standard PLA+

Functional prototypes, general 3D printing, detailed prints, educational purposes.Measurement Value Unit Test Method Maximum Tensile Strength 41 MPa ASTM D638 Tensile Strength at Yield 37 MPa ASTM D638 Tensile Modulus 3.2 GPa ASTM D638 Tensile Elongation 1.8 % ASTM D638 Notched Impact 26 J/m ASTM D256 -

Tough Pro PLA+

Mold work, lost foam casting, investment casting with molds, form and fit, functional prototypes.Measurement Value Unit Test Method Tensile Strength 5,802 (40) MPa D638 Tensile Modulus 416 (2,865) MPa D638 Flexural Strength 10,588 (73) MPa D790 Flexural Modulus 350 (2,414) MPa D790 Notched Izod Impact [amorphous] 2.99 (160) J/m D256 Notched Izod Impact [crystalline] 4.37 (233) J/m D256 Heat Distortion Temperature (°C) 66 psi 75-85 0.45 MPa E2092 -

TPU 58D-AS

ESD-safe dust caps, abrasion-resistant panel covers, ESD-safe jigs and fixtures, no-fly parts, impact-rated components.Measurement Value Unit Test Method Ultimate Tensile Strength 33.0 (1.7) MPa ISO 37 Tensile Modulus 0.142 (0.004) GPa ISO 37 Strain at Break 740 (30) % ISO 37 Notched Izod Impact Strength 54 (5) kJ/m2 ISO 180/A -

TPU 74D-Z

ABS ESD replacement, electronics manufacturing jigs and fixtures, abrasion-resistant covers, snap-fit connectors, heavy load vibration isolation, impact-rated structural components.Measurement Value Unit Test Method Ultimate Tensile Strength 36.4 (1.2) MPa ISO 37 Tensile Modulus 0.318 (0.009) GPa ISO 37 Strain at Break 730 (29) % ISO 37 Notched Izod Impact Strength N kJ/m2 ISO 180/A -

TPU 80A-Z

ESD jigs, non-marring grippers, soft springs, bumpers, isolation mounts, seals, suction cups, plugs.Measurement Value Unit Test Method Tensile Strength 22 MPa ASTM D638 Elongation at Break 729 % ASTM D638 -

TPU 95A-Z

ESD jigs, vibration damping feet, grommets, bushings, protective inserts, vibration isolation, soft grips, flexible hose.Measurement Value Unit Test Method Tensile Strength 34 MPa ASTM D638 Elongation at Break 639 % ASTM D638 -

Ultrasint® PA11 (Black)

Interior car parts, Bumper components, Functional prototypes and spare paMeasurement Value Unit Test Method Tensile Strength – X/Z 45 MPa ISO 527-2 Tensile Modulus – X/Z 1150/1200 MPa ISO 527-2 Tensile Elongation at Break – X/Z 42/34 % ISO 527-2 Flexural Modulus – X/Z 1300 MPa ISO 527-2 Charpy Impact Strength (unnotched) No break/75 kJ/m² ISO 179-1 Izod Impact Strength (unnotched) No break/63 kJ/m² ISO 180 -

Ultrasint® PA11 (White)

Interior car parts, Bumper components, Functional prototypes and spare paMeasurement Value Unit Test Method Tensile Strength – X/Z 45/46 MPa ISO 527-2 Tensile Modulus – X/Z 1100/1250 MPa ISO 527-2 Tensile Elongation at Break – X/Z 45/31 % ISO 527-2 Flexural Modulus – X/Z 1250/1300 MPa ISO 527-2 Charpy Impact Strength (unnotched) 198/85 kJ/m² ISO 179-1 Izod Impact Strength (unnotched) No break/54 kJ/m² ISO 180 -

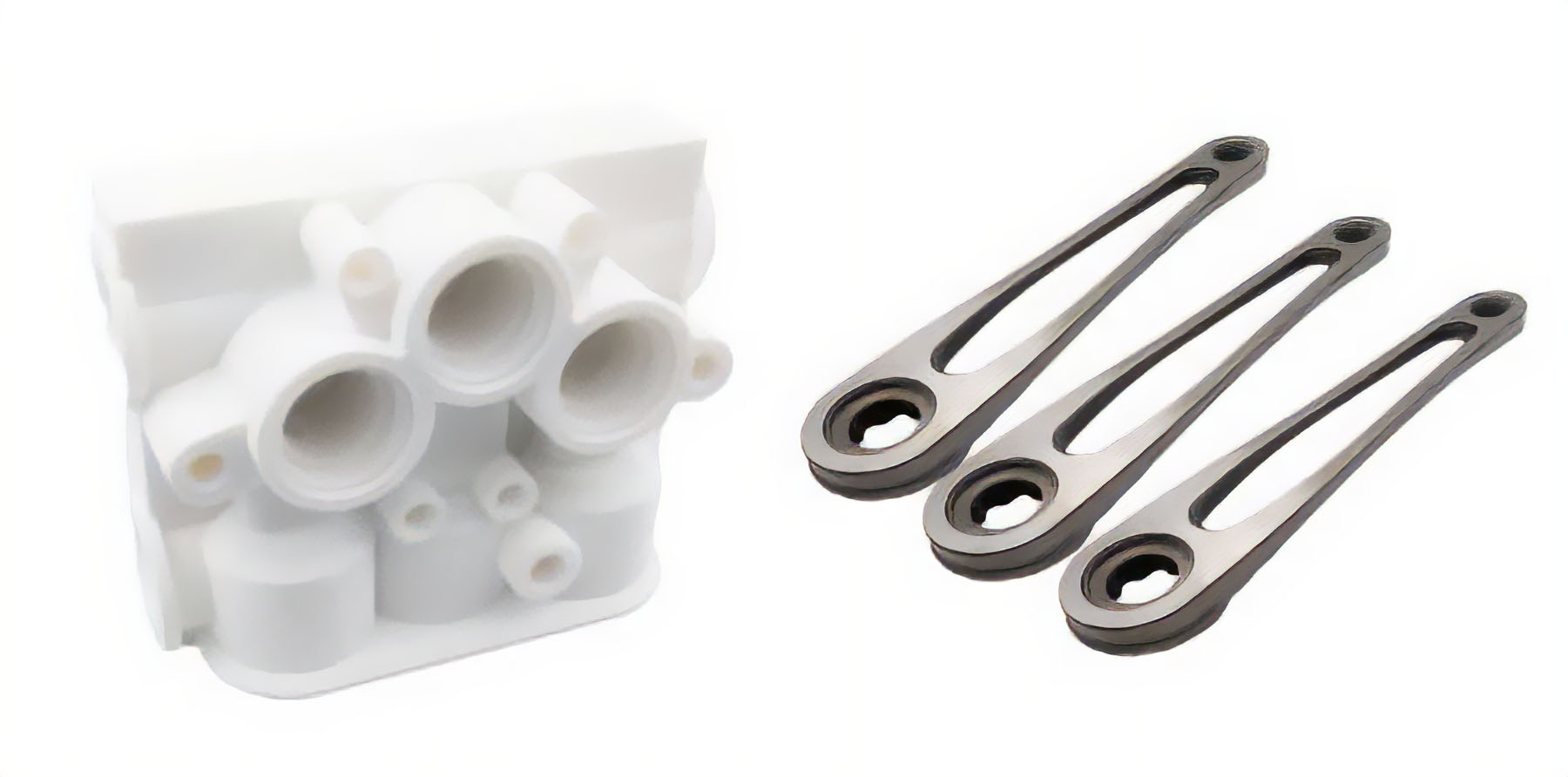

Ultrasint® PA11 Black Carbon Fiber

Individual motorsport parts, Lightweight structures, Aerodynamic components, Metal replacement partsMeasurement Value Unit Test Method Tensile Strength – X/Z 82/45 MPa ISO 527-2 Tensile Modulus – X/Z 5900/2260 MPa ISO 527-2 Tensile Elongation at Break – X/Z 7/3.6 % ISO 527-2 Flexural Modulus – X/Z 5800/2500 MPa ISO 527-2 Charpy Impact Strength (unnotched) – X/Z 54/33 J/m² ISO 179-1 Izod Impact Strength (unnotched) 48/34 J/m² ISO 180 -

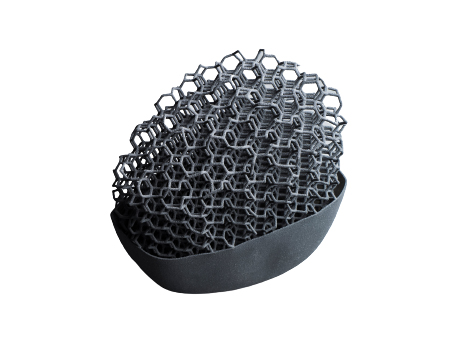

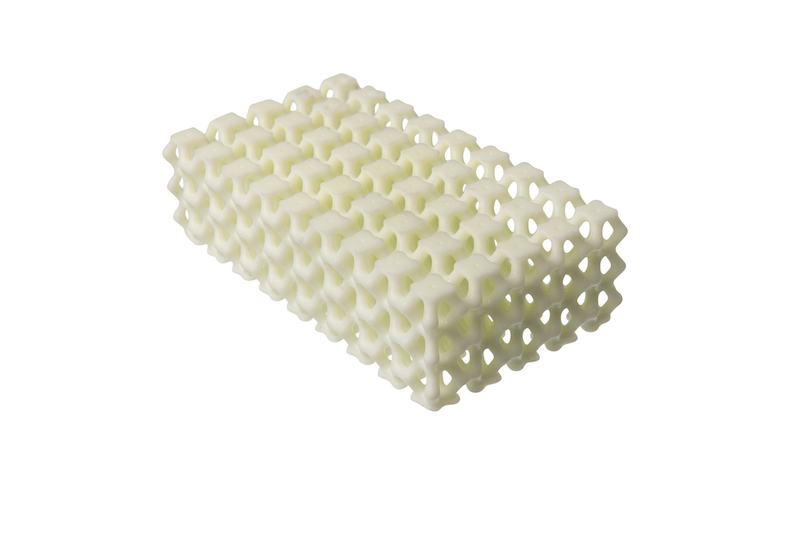

Ultrasint® TPU 88A (Black)

Sports protection equipment, Footwear, Orthopedic models, Car interior componentsMeasurement Value Unit Test Method Tensile Modulus – X/Z 85 MPa ISO 527 Ultimate Tensile Strength – X/Z 8/5 MPa DIN 53504 Elongation at Break – X/Z 360/100 % DIN 53504 Flex Modulus – X/Z 85 MPa ISO 178 Compression Set B – X/Y 24/28 % ISO 815 Rebound Resilience – X/Z 63/64 % DIN 53512 Charpy Notched, 23° No break ISO 179 Hardness Shore A 86-88 ISO 7619 -

Ultrasint® TPU 88A (White)

Sports protection equipment, Footwear, Orthopedic models, Car interior componentsMeasurement Value Unit Test Method Tensile Modulus – X/Z 75 MPa ISO 527 Ultimate Tensile Strength – X/Z 8/7 MPa DIN 53504 Elongation at Break – X/Z 280/130 % DIN 53504 Flex Modulus – X/Z 70 MPa ISO 178 Compression Set B – X/Y 24 % ISO 815 Rebound Resilience – X/Z 63 % DIN 53512 Charpy Notched, 23° No break ISO 179 Hardness Shore A 88-90 ISO 7619 -

xABS3843

Automation Machinery, Robotics, Bracket, Levers and Arms for Manufacturing Stations, Parts and AssembliesMeasurement Value Unit Test Method Tensile Modulus 1353 MPa ASTM D638 Ultimate Tensile Strength 39 MPa ASTM D638 Tensile Elongation at Break 62 % ASTM D638 Flex Modulus 1783 MPa ASTM D790 Flex Strength 30 MPa ASTM D790 Hardness (Shore D) 84 ASTM D2240 Notched Izod 53 J/m ASTM D256 HDT @0.45 MPa 63 oC ASTM D648 Water Absorption (24 hr) 1.94 % ASTM D570 -

xCERAMIC3280

High Temperature, High Speed, Wind Tunnel Testing, Consumer Products. Material data represents UV Post Cure.Measurement Value Unit Test Method Tensile Modulus 10300 MPa ASTM D638 Tensile Strength 85 MPa ASTM D638 Elongation 1.2 % ASTM D638 HDT at 0.45 Mpa 205 °C ASTM D648 Solid Density 1.73 g/cm³ ASTM D792 Shore Hardness 96 D ASTM D2240 Water Absorption 0.29 % ASTM D570 -

xDENT201-Beige

High-Resolution, Accuracy, Great Dimensional Stability.Measurement Value Unit Test Method Tensile Stress at Break 54.92 MPa ASTM D638 Young’s Modulus 2366.65 MPa ASTM D638 Elongation at Failure 4.03 % ASTM D638 Shore Hardness (solid) 80 Shore D ASTM D2240 Viscosity @ 25°C (77°F) 350 mPa*s (cP) Cone/Plate Rheometer Liquid Density 1.05~1.1 g/cm3 ASTM D4052-18a -

xDENT201-Gray

High-Resolution, Accuracy, Great Dimensional Stability.Measurement Value Unit Test Method Tensile Stress at Break 54.92 MPa ASTM D638 Young’s Modulus 2366.65 MPa ASTM D638 Elongation at Failure 4.03 % ASTM D638 Shore Hardness (solid) 80 Shore D ASTM D2240 Viscosity @ 25°C (77°F) 350 mPa*s (cP) Cone/Plate Rheometer Liquid Density 1.05~1.1 g/cm3 ASTM D4052-18a -

xDENT341-Beige

High-Resolution, Accuracy, Great Dimensional Stability.Measurement Value Unit Test Method Tensile Stress at Break 40.83 MPa ASTM D638 Young’s Modulus 1860.28 MPa ASTM D638 Elongation at Failure 2.69 % ASTM D638 Shore Hardness (solid) 84 Shore D ASTM D2240 Viscosity @ 25°C (77°F) 100-200 mPa*s (cP) Cone/Plate Rheometer Liquid Density 1.05~1.1 g/cm3 ASTM D4052-18a -

xESD

Nano-engineered ESD resin for Isotropic Static Dissipative PerformanceMeasurement Value Unit Test Method Tensile Strength 68.1 MPa ASTM D 638-14 Tensile Modulus 2.6 GPa ASTM D 638-14 Yield Strength 40.6 MPa ASTM D 638-14 Elongation at Break 3.8 % ASTM D 638-14 Flexural Strength 97.4 MPa ASTM D 790-15* Flexural Modulus 1.8 GPa ASTM D 790-15* Notched IZOD 24 J/m ASTM D 256-10 Shore “D” 87 ASTM D 2240-15 Heat Deflection @1.8MPa 91.4 ºC ASTM D 648-16 Heat Deflection @0.45MPa 91.3 ºC ASTM D 648-16 Surface Resistance 107 Ω ASTM D 257 Water Absorption 0.9 % ASTM D 570-98 Density 1.1 g/cm3 25°C Viscosity 878.1 cps 25°C -

xFLEX402-Black

Semi-Firm, Rubberlike Elastomer, Prototypes and Production PartsMeasurement Value Unit Test Method Ultimate Tensile Strength 5.3 MPa ASTM D638 Young’s Modulus 54.6 MPa ASTM D638 Elongation at Break 236 % ASTM D638 Energy Return 30 – 35 % Proprietary Shore Hardness (5s) 83 A ASTM D648 Water Absorption (24hr) 3.62 % ASTM D570 -

xFLEX475-Black

Pipes and Manifolds, Handles and Grips, Seals and Gaskets, Sportswear and Footwear MidsolesMeasurement Value Unit Test Method Young’s Modulus 1.8 MPa ASTM D638 Ultimate Tensile Strength 2.2 MPa ASTM D638 Tensile Elongation at Break 162 % ASTM D638 Energy Return 47 % Internal Tear Strength 6.07 kN/m ASTM D624 Hardness (shore A) 40 A ASTM D2240 -

xFLEX475-White

Pipes and Manifolds, Handles and Grips, Seals and Gaskets, Sportswear and Footwear MidsolesMeasurement Value Unit Test Method Young’s Modulus 3.8 MPa Ultimate Tensile Strength 3.2 MPa ASTM D638 Tensile Elongation at Break 163 % ASTM D638 Energy Return 39.13 % Internal Tear Strength 8.9 kN/m ASTM D624 Hardness (shore A) 65 A ASTM D2240 -

xMODEL15-Black

High Accuracy, Fast Printing Photopolymer Serves Wide Variety of Modeling ApplicationsMeasurement Value Unit Test Method Modulus of Elasticity 1800 MPa ASTM D638 type4 Tensile Strength 55 MPa ASTM D638 type4 Elongation at Break 10 % ASTM D638 type4 Density 1.09 – 1.10 g/cc GB/T 4472 Viscosity 200 – 300 MPA.s GB/T 22235 Hardness 78 – 80 Shore D ASTM D2240 Heat Deflection Temperature 50 °C GB/T 1634 Water absorption 0.7 % Immersion after 24 hrs -

xMODEL15-Gray

High Accuracy, Fast Printing Photopolymer Serves Wide Variety of Modeling ApplicationsMeasurement Value Unit Test Method Modulus of Elasticity 1800 MPa ASTM D638 type4 Tensile Strength 55 MPa ASTM D638 type4 Elongation at Break 10 % ASTM D638 type4 Density 1.09 – 1.10 g/cc GB/T 4472 Viscosity 200 – 300 MPA.s GB/T 22235 Hardness 78 – 80 Shore D ASTM D2240 Heat Deflection Temperature 50 °C GB/T 1634 Water absorption 0.7 % Immersion after 24 hrs -

xMODEL17-Clear

High-Clarity, Prototyping, Feature Fine Detail, Product PackagingMeasurement Value Unit Test Method Young’s Modulus 1358 MPa ASTM D638 Ultimate Tensile Strength 37 MPa ASTM D638 Tensile Elongation at Break 28 % ASTM D638 Flex Modulus 1467 MPa ASTM D790 Flex Strength 57 MPa ASTM D790 HDT at 0.45 MPa 47 °C ASTM D648 Notched Izod 47 J/m ASTM D256 Water Absorption 0.24 % ASTM D570 -

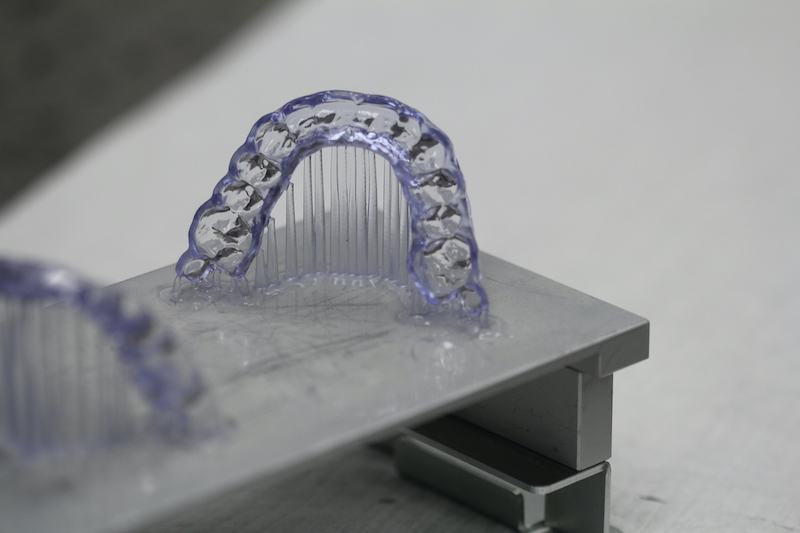

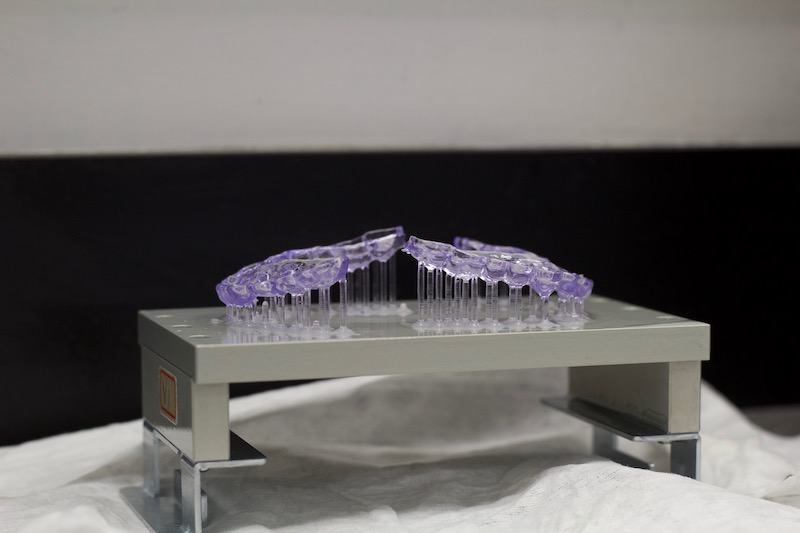

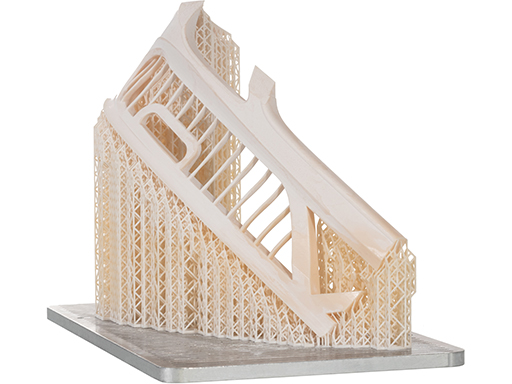

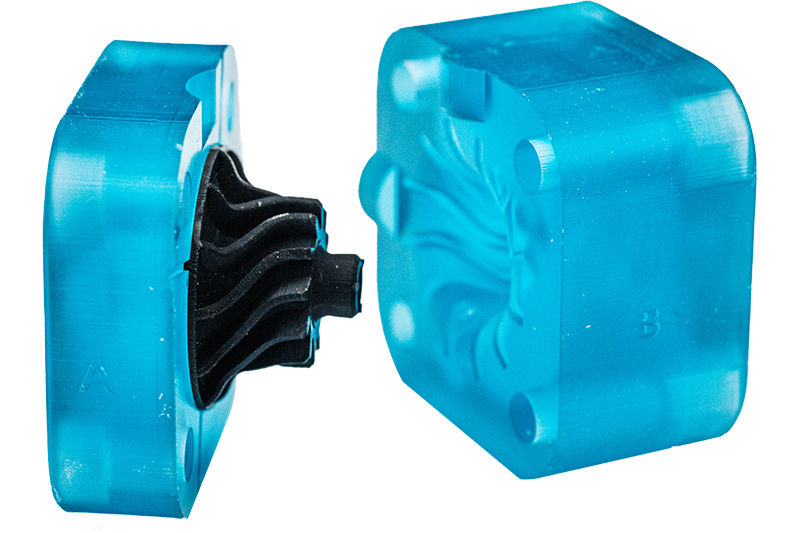

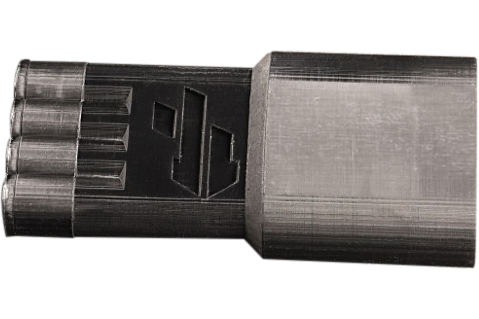

xMOLD

xMOLD is a high-performance dissolvable resin developed for Freeform Injection Molding (FIM).Measurement Value Unit Test Method Ultimate tensile strength 38 ± 3 MPa ASTM D638 Young’s Modulus 1152 ± 284 MPa ASTM D638 Tensile stress at break 31 ± 2 MPa ASTM D638 Hardness (Post-cure) Shore D 80 ASTM D2240 Toughness 18 ± 4 MPa ASTM D638 Thermal conductivity 0.187 W/m K ISO 22007-2 (2015) Dissolvability Fully dissolvable Submerged in demolding solvent Color Transparent blue Visual -

xPEEK147

Production Parts, Tooling and MoldingMeasurement Value Unit Test Method Tensile Modulus 2820 MPa ASTM D638 Ultimate Tensile Strength 65 MPa ASTM D638 Tensile Elongation at Break 3 % ASTM D638 Flex Modulus 3491 MPa ASTM D790 Flex Stress 134 MPa ASTM D790 Hardness (Shore D) 94 ASTM D2240 Notched Izod 15 J/m ASTM D256 HDT @0.45 MPa 222 oC ASTM D648 Water Absorption (24hr) 0.24 % ASTM D570 -

xPP405-Black

Packaging, Piping, Consumer and Industrial ApplicationsMeasurement Value Unit Test Method Tensile Modulus 1300 MPa ASTM D638 Ultimate Tensile Strength 35 MPa ASTM D638 Tensile Elongation at Break 100 % ASTM D638 Flex Modulus 1383 MPa ASTM D790 Hardness (Shore D) 76 ASTM D2240 Notched Izod 62 J/m ASTM D256 HDT @0.45 MPa 53 oC ASTM D648 Water Absorption 1.00 % ASTM D570 -

xPRO1100-Black

Automotive components: connectors, brackets, and housings, aerospace prototypes, engineering parts, consumer productsMeasurement Value Unit Test Method Tensile Modulus 3010 MPa ASTM D638 Tensile Strength at break 71 MPa ASTM D638 Elongation 4 % ASTM D638 Flex Modulus 2790 MPa ASTM D790 Flexural Stress 125 MPa ASTM D790 Hardness (Shore D) 84 ASTM D2240 IZOD Impact (Notched) 21 J/m ASTM D256 HDT @0.45 MPa 112 °C ASTM D648 Water Absorption (24hr) 0.14 % ASTM D570 -

xPRO9400-FR

Measurement Value Unit Test Method Tensile Modulus 4060 MPa ASTM D638 Ultimate Tensile Strength 78 MPa ASTM D638 Elongation 2.5 % ASTM D638 HDT at 0.45 MPa >236 °C ASTM D648 HDT at 1.82 Mpa 141 °C ASTM D648 Flammability V0 UL94 (2mm) Glass Transition Temperature (DMA, tan(d)) 175 °C ASTM D4065 Viscosity at 30°C (86°F) 350 cP ASTM D7867 Shore Hardness 88 D ASTM D570 Water Absorption (24hr) 0.65 % ASTM D570 -

Xyon

Jigs, fixtures, tooling, functional prototypes, brackets, automotive parts, component housings.Measurement Value Unit Test Method Ultimate Tensile Strength 70.7 (5.1) MPa ISO 527-2 Tensile Modulus 9.38 (0.28) GPa ISO 527-2 Strain at Break 1.3 (0.2) % ISO 527-2 Flexural Strength 131 (1) MPa ISO 178 Flexural Modulus 8.06 (0.10) GPa ISO 178 Notched Izod Impact Strength 5.6 (0.4) kJ/m2 ISO 180/A

NEW!

Download 2024 Resin Material Guide

Latest and greatest resin materials in 2024 featuring xMOLD, xESD, FR, xDENT, and more.