- Markforged Onyx Filament Review & Alternatives [2024] - December 11, 2024

- 17 Best Professional 3D Printers: Commercial, Desktop, & Industrial [2024] - December 10, 2024

- Best 3D Printers (Industrial, Desktop, & More) [2024 Guide] - July 20, 2024

Whether you’re an engineer, professional builder, or hobbyist, 3D printing technology offers a fast and cost-effective solution for creating precise models, parts, and products.

Of course, when considering using 3D printing technologies, a common question arises: how much does a 3D printer cost?

This article will look at the different types of 3D printers available on the market today and explore their various price points so that you can make an informed decision when choosing your 3D printer.

Is it Expensive to 3D Print?

Material types, the complexity of a design, labor requirements, and other factors all impact costs. The largest expense, of course, is the initial purchase of the 3D printer.

But there’s more to consider than just the purchasing cost. For example, while resin-based printers are typically more expensive upfront than FDM 3D printers, they almost always provide more value to professional users. Vat polymerization delivers better part quality, smoother finishes and finer detail, greater throughput, and build chamber utilization (especially mSLA 3D printers).

So depending on the 3D printing technology being used, 3D printing can be very cost-effective. A fully functional and efficient 3D printer can help you scale a business, bring a concept to reality, and create more sustainable manufacturing practices.

Average 3D Printer Price by Type

The average prices for different types of 3D printers vary depending on the functions and capabilities of each machine.

Here are some of the average 3D printer prices by type:

3D Printers for Beginners

Cost range: $100-$500

These are the most basic 3D printers. They’re easy to use and good for printing smaller objects.

Beginner 3D printers are often DIY or kit-based machines, meaning the users must assemble them before they can start printing. They generally aren’t suitable for larger print jobs since they have limited build capacities.

Beginner 3D printers are best for learning the basics of 3D printing and are not designed for professional or industrial applications. Users shouldn’t expect high accuracy, quick print times, or extremely smooth surface finishings.

Elegoo, Flash Forge, and Creality all offer beginner 3D printers.

Hobbyist 3D Printers

Cost range: $500 – $1,500

Hobbyist 3D printers are designed for users who want to make their own products at home. These printers come both as kits and ready-made.

Hobbyist 3D printers are suitable for a wide range of projects and offer better print resolution and faster printing speed than entry-level 3D printers. Some hobbyist-grade machines even feature auto-leveling functions, which improve the accuracy of prints.

Users can expect high-quality prints at decent speeds. The print size is usually small to medium, and some machines can print objects larger than ten inches. They can also support materials like PLA and ABS for various projects. However, these printers are not for professional use.

3D printing companies Creality, PRUSA, and Flashforge make hobbyist 3D printers.

Professional Desktop 3D Printers

Cost range: $1,000 – $10,000

Professional desktop 3D printers have industrial-quality construction and high-end printing capabilities. They’re best suited for professional use, such as for rapid prototyping and industrial-level productions. Professional users invest in desktop 3D printers because they’re portable (compared to the footprint of the factory-sized 3D printers), durable, and more affordable.

Professional 3D printers are designed to be extremely precise and accurate and offer larger build plates, dual extruders for multi-material prints (in FDM printers) , and advanced slicing software. These machines can typically print materials like PLA, ABS, PETG, Nylon, TPE/TPUs, and more.

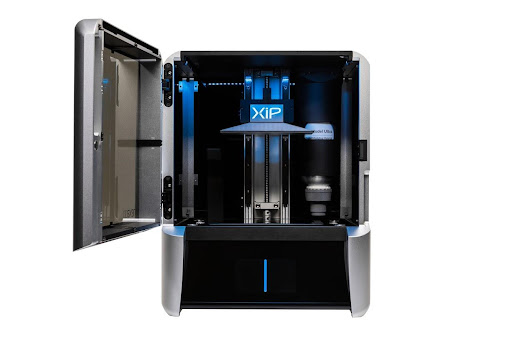

An example of a professional desktop 3D printer is Nexa3D’s XiP 3D printer which offers industrial-quality 3D printing at an incredible desktop price. It’s compact but with a large build volume and fast print speeds for high-quality prototypes as well as low-volume production parts.

Large Industrial 3D Printers

Cost range: $10,000 – $100,000+

Industrial 3D printers can have five, six, and seven-figure prices due to their advanced features, material range, and build quality. They’re designed for large-scale production with high precision, accuracy, speed, and reliability. The cost of maintenance, repairs, and labor can also be higher for these machines in comparison to other 3D printers.

Industrial 3D printers use various 3D printing methods including SLA, DLP, FDM, and SLS to enable users to produce parts with the highest precision and accuracy. They’re extremely durable and capable of printing various materials, including metals.

Advanced industrial 3D printers like Nexa3D’s NXE Pro series are fast, have large build volumes, and have 4K LCD screens for incredible detail, accuracy, and resolution. The NXE Pro printers offer a range of material options for a wide range of applications.

What Impacts 3D Printer Pricing and Costs?

While the 3D printer is the bulk of the cost, there are additional factors that impact the price.

Materials

Over 30 materials are available for Nexa3D’s photopolymer NXE 400.

- Thermoplastics: Thermoplastics are highly durable, moldable, and lightweight. The most common types of thermoplastics used in 3D printing are polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polylactic acid (PLA). Thermoplastics also include various resin and filament materials.

- Metals: Metal materials are one of the most expensive materials in 3D printing. Some types of metals used in 3D printing include stainless steel, titanium, brass, aluminum, and copper alloys. The process of 3D printing metal is quite different from other materials. It involves using a high-powered laser to melt the metal powder into the desired shape (this process is referred to as Direct Metal Laser Sintering).

- Photopolymers: Photopolymers are polymers that solidify when exposed to light. Shorter wavelength light causes a reaction that changes a photopolymer’s structure and mechanical and chemical buildup. Photopolymers are more versatile than other materials and can create complex objects that other methods cannot. Therefore, resin 3D printers (which use photopolymers) have faster prints, better surface finishes, accuracy, and precision.

- Composites: Composite materials comprise two or more different 3D materials. Usually, composites are made up of a thermoplastic base material and other reinforcing elements like carbon fiber, nylon, fiberglass, graphene, or Kevlar. Composites are commonly used in selective laser sintering 3D printing.

Material costs depend on the type of 3D printer used. Generally, FDM 3D printers use filaments, while resin 3D printers use resins or other consumables. The average filament costs between $20 and $50 per kilogram, but the cost may vary depending on the material used for printing. And, though Filament 3D printing can use materials like Nylon, PA, PETG, TPU, PEEK, and PEI can be used, they’re often limited to specific professional FDM printers that can support them.

For SLA printers, resins cost around $50 for a 500mL bottle, while the PLA nylons for SLS printers may cost around $60 per kilogram.

Size

Generally, larger-sized objects require more materials, a longer time to finish a print job, and a larger (more expensive) printer.

Complexity

Complex designs are more expensive to produce because they require a higher density infill rate, more materials, and often a longer printing time.

Software

Some 3D printers come with proprietary software while others use open-source software like Cura or Slic3r. Although proprietary software can be more expensive than open-source, it often offers a better range of features and capabilities.

Electricity

The electrical usage of 3D printers is an essential factor a user considers when purchasing. The electricity usage of a 3D printer varies depending on the material and the print size. So while the average consumer-grade 3D printers use around 0.5kWh, industrial 3D printers can use a lot of electricity and can require higher voltage outlets.

Advanced 3D printers will factor in electrical usage and ensure that it produces high-quality prints without consuming much electricity.

Post-processing

Industrial post-processing requires additional materials (such as paint, adhesives, and coatings), post-processing accessories, additional time to completion, and even skilled technicians to ensure the best yield.

However, Nexa3D’s xWash and xCure post-processing technologies integrate post-processing features so that operators can save on both labor and material costs.

Labor

Labor includes the cost of assembly, training, accessories, maintenance, and repair of 3D printers. Maintenance costs include the replacement of parts, the calibration of the machine, and other technical services.

The best 3D printers come with a warranty or technical support; however, some may require additional labor costs for upkeep.

Outsourced vs. In-house 3D Printing

Outsourcing 3D printing means longer new product development cycles and lead times. You often need to pay per part and there are more transportation costs and fees.

Purchasing an in-house printer offers more reliability, an easier implementation of designs, and more control. Instead of relying on a service provider and their capabilities, you can improve turnaround times and get your product to market faster.

You don’t need a large industrial printer to do this. High-quality professional desktop 3D printers provide the same resolution, layer thickness, accuracy, and print speeds while being both accessible and affordable.

Nexa3D’s XiP offers industrial-quality 3D printing at an affordable desktop price. The XiP combines a compact footprint with a large build volume and fast print speed to deliver high-quality prototypes right to your desktop.

3D Printer Cost FAQs

How do 3D printers work?

3D printers take a 3D model created in a computer-aided design (CAD) program and turn it into a physical object. The printer is fed with materials such as plastic filament, resin, metals, etc., which are melted using heat or light layer by layer. Of course, the specific process depends on what 3D technology is used.

For example, SLA 3D printers use a laser beam and a set of programmable mirrors to aim and trace every layer part and cure the resin as it passes. However, its mSLA counterpart uses a high-resolution LCD to generate a “mask” of the layer image sitting between an LED array and a resin vat at ultrafast speeds.

What is the average cost of a 3D printer?

Entry-level beginner 3D printers are the most affordable option among other technologies and can range from $250 to $3,000. Professional desktop 3D printers range from $1,000 and $10,000 while industrial printers can start at $10,000 and reach in the millions.

How much does 3D printing cost per hour?

3D printing operations usually cost around $0.40 per hour, but varies depending on the amount of power required. Software packages like CASTOR help determine more accurate metrics on KWh/hour usage.

Benefits of 3D Printing

While 3D printing does have upfront costs, the benefits almost always outweigh the initial investment.

Reduced Operational Costs

The operational cost of 3D printing is significantly lower than traditional fabrication methods because it requires lesser labor and tooling. Plus, 3D printing is an additive process. In subtractive manufacturing, parts are created by cutting away materials from a block until the desired shape is achieved.

Additive manufacturing builds objects layer-by-layer, resulting in less waste and reduced need for materials. This makes it a cost-effective option for businesses producing high-quality parts at a fraction of the cost.

Flexible Use-cases

3D printing technology can make a variety of products including medical implants, consumer electronics, and industrial parts. With the help of 3D printing, companies can quickly produce custom parts and explore creative constructions with intricate details.

For instance, Williams Racing F1 adopted 3D innovation in the auto industry. The company utilizes Nexa3D’s NXE 400 Pro to manufacture prototype high-performance parts and testing operations. Williams Racing F1 uses NXE400’s ultrafast printing to achieve fast iteration and facilitate a rapid print/check/modify/print/repeat cycle. This provides a standard level of refinement in a limited timeframe.

Freedom of Design

3D printing allows for the creation of products and shapes that can’t be made through other manufacturing processes. Whether it’s internal channels, organic shapes, or extremely complex features, 3D printing provides an entirely new world of design and production capabilities.

Improved Sustainability

3D printing saves materials, eliminates the need for tooling, and helps reduce waste. As an additive manufacturing technology, 3D printing typically requires fewer resources and is an ideal solution for companies looking to reduce their environmental impact.

3D printing also offers great flexibility and optimization of the supply chain. Businesses can print customized parts on demand, eliminating the need for overproduction or inventory storage.

3D Printing Costs: Are They Worth It?

Although 3D printing has some upfront costs, the benefits are worth it. With improved sustainability, faster product development cycles, and reduced operational costs, businesses can leverage this technology to become more efficient and profitable.

Plus, businesses can choose from various 3D printers that work within their budget. To make 3D printing more accessible for professionals, Nexa3D is building a sustainable digital supply chain of the fastest high-quality 3D printers in the industry at an affordable price.

Nexa3D printers have the largest build area in their class with incredible image quality, enabling businesses and professionals to print quickly and affordably–without compromises.

Experience it yourself with a free sample part from our resin 3D printers.

Or, learn about the latest 3D printing materials for ultrafast 3D printing.